Production method and application of glass microscale aspirator

A pipette and micro-volume technology, applied in the field of micromanipulation and molecular biology, to achieve the effect of simple method and simple collection of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

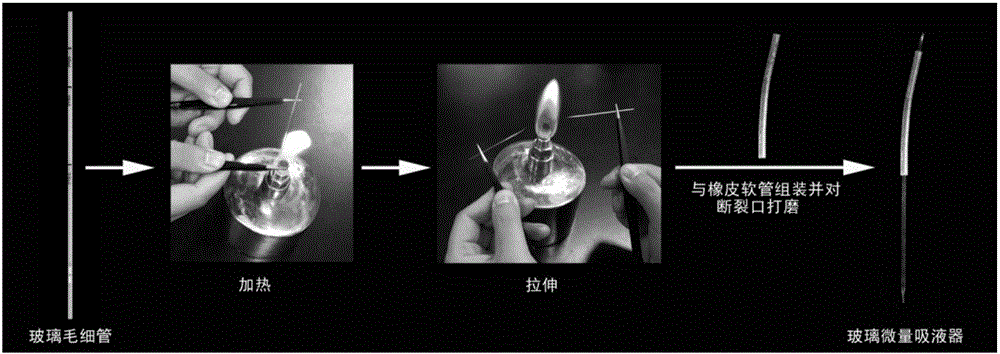

[0039] A preparation method of a glass micropipette, comprising:

[0040] The 1mm glass capillary is heated on the flame of an alcohol lamp. After the heated area of the capillary becomes soft, it is slowly pulled away from both ends of the capillary. The capillary finally breaks and forms a very thin tip. The formed tip is polished to form an opening with a diameter of 25-30 μm. One end of the tip is connected with a rubber hose, and the end of the rubber hose is sealed with a glass stopper to obtain a glass micropipette ( figure 1 ).

[0041] The glass stopper is capillary fired.

Embodiment 2

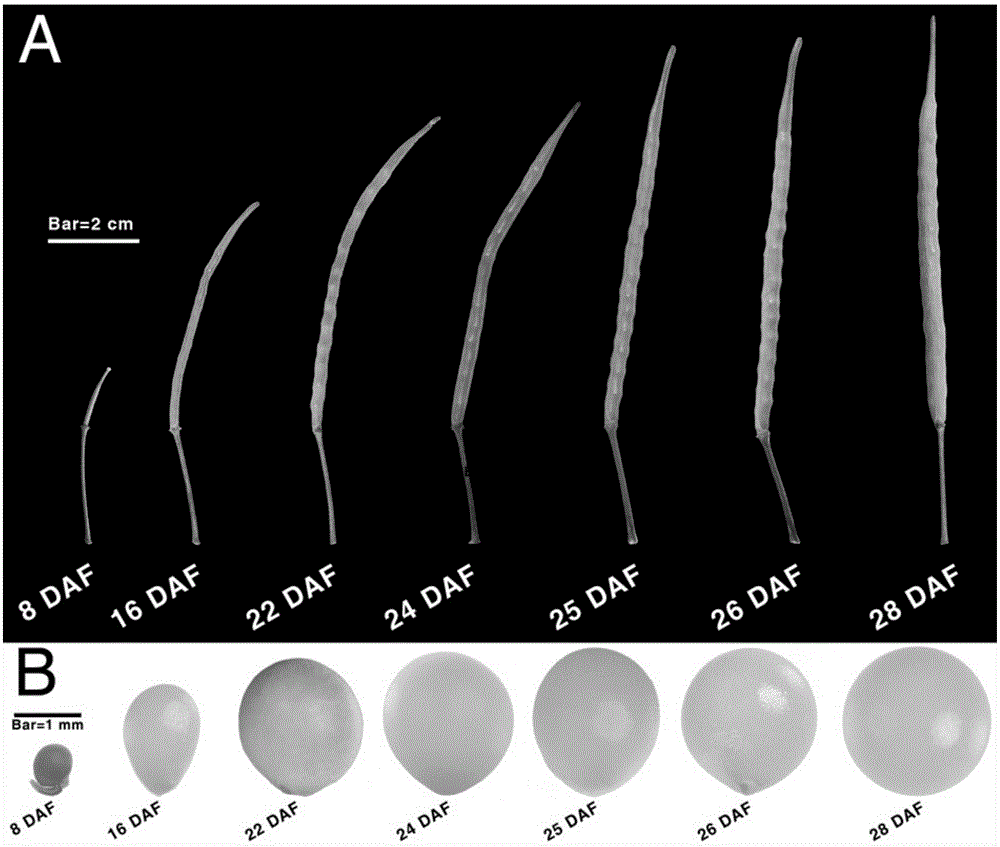

[0043]Determining the stage of development of ovules for isolation of liquid endosperm

[0044] In this example, the flowers of Brassica napus ZY036 that are blooming are marked with a thin line. Subsequently, the siliques of 8 days, 16 days, 22 days, 24 days, 25 days, 26 days and 28 days after flowering were taken respectively for observation, and it was found that the length of the siliques was approximately finalized in 25 days after flowering ( figure 2 Middle A). In addition, the ovules of different time periods were separated under a dissecting microscope, and then observed under a stereomicroscope, it was found that the volume of the ovules changed the fastest from 8 days to 22 days after flowering, and the volume of the ovules was basically finalized on the 25th day ( figure 2 Medium B). Therefore, the ovules 25 days after flowering were finally selected as the material for separating the endosperm, which was used in the following examples.

Embodiment 3

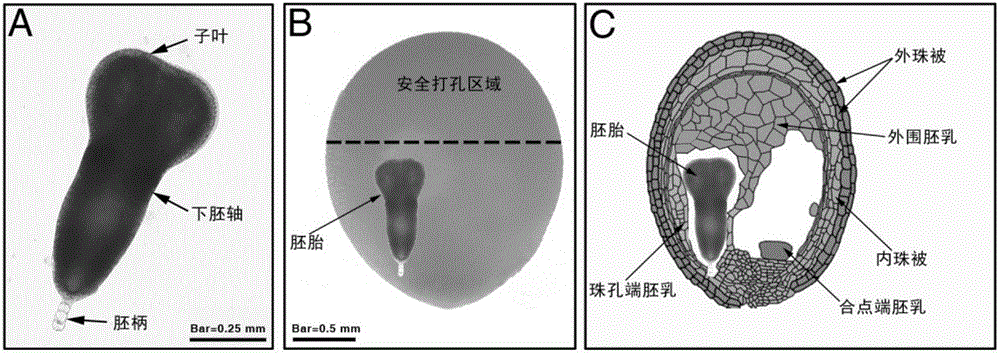

[0046] Selection of the Best Perforation Position on the Ovule Surface of Brassica napus ZY036

[0047] The embryos in ZY036 25DAF ovules were separated under an inverted microscope (OLYMPUS IX71) by stripping needles, and their morphology was observed. It was clear that the embryos of 25DAF ZY036 were torpedo stage embryos (torpedo stage) ( image 3 Middle A); according to the size and morphological structure characteristics of ZY036 25DAF ovules and embryos, the position and occupied space of 25DAF embryos in the whole ovule were simulated by Photoshop ( image 3 Medium B and image 3 Middle C), it is clear that on the surface of the ovule far away from the embryo is the best reasonable position for punching ( image 3 Above the black dotted line shown in B is the punching safe area).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com