A kind of microorganism immobilization agent and its preparation method and application

A microbial immobilization and biochar technology, which is applied in the field of environmental engineering and pollution treatment engineering, can solve the problems of treatment technology reports, etc., and achieve the effects of wide sources, increased adhesion area, and improved specific surface and adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

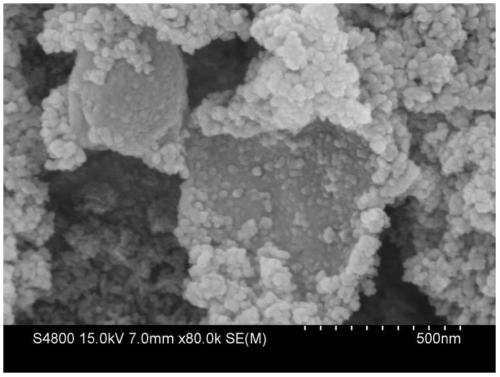

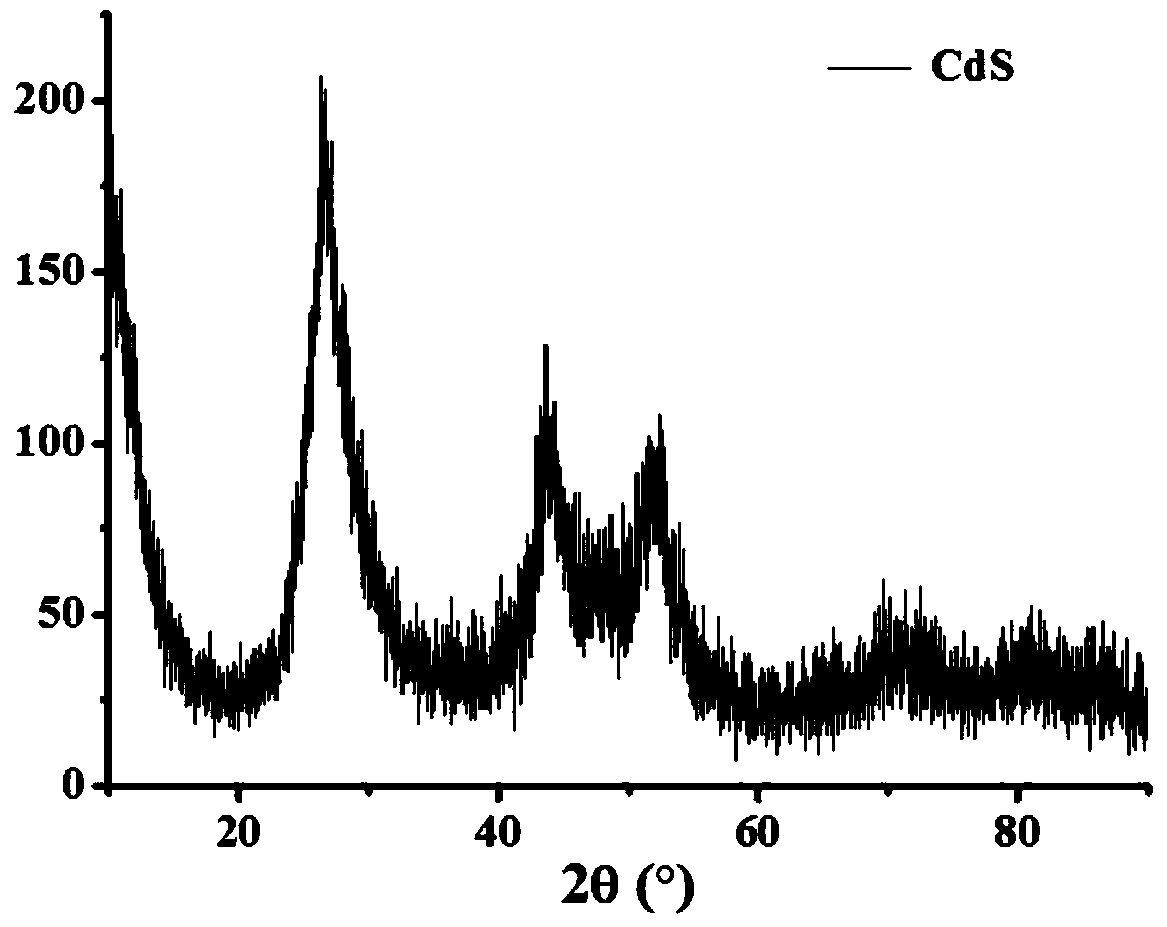

[0045] One, the preparation method of microorganism immobilization agent

[0046] (1) Preparation of biochar: Take the straw, wash it, air dry it, crush it, pass it through a 2mm sieve, and pyrolyze it under anaerobic conditions at 600°C for 2 hours, and then carbonize it; after the carbonized product is naturally cooled, grind it and take 200-400 mesh The retentate between the sieves was treated with 1mol / L hydrochloric acid for 2 hours to remove ash, washed with distilled water until the washing liquid was neutral, and dried at 80°C to obtain biochar.

[0047] (2) Fe 2 o 3 , Fe 3 o 4 load of:

[0048] a: Take 100g of biochar obtained in step (1) and add it to 1L biochar containing 0.25mol FeCl 3 In the aqueous solution, add NaOH solution again, after stirring for 4h, collect the precipitate; Fe 3+ The molar ratio with NaOH is 1:7;

[0049] b: Wash the precipitate with deionized water for 6 times, mix the precipitate with NaOH solution and place it in a hydrothermal ke...

Embodiment 2

[0085] In recovery example 1, the modified biochar IV loaded with nano-CdS after the treatment of heavy metal and organic waste water was washed 5-6 times with deionized water, dried at 80°C, and used to treat Cr(VI): 85.2 mg / L, 4-chloroaniline: 27.9mg / L, 4-chlorophenol: 31.8mg / L, rhodamine B dye: 25.3mg / L, waste water with a pH of 6.5. The material dosage is 15g / L.

[0086] Under the condition of stirring, the removal rates of Cr(VI), 4-chloroaniline, 2,4-chlorophenol and rhodamine B dyes were 99.1%, 99.2%, 98.2% and 96.8% respectively after light reaction for 8 hours.

Embodiment 3

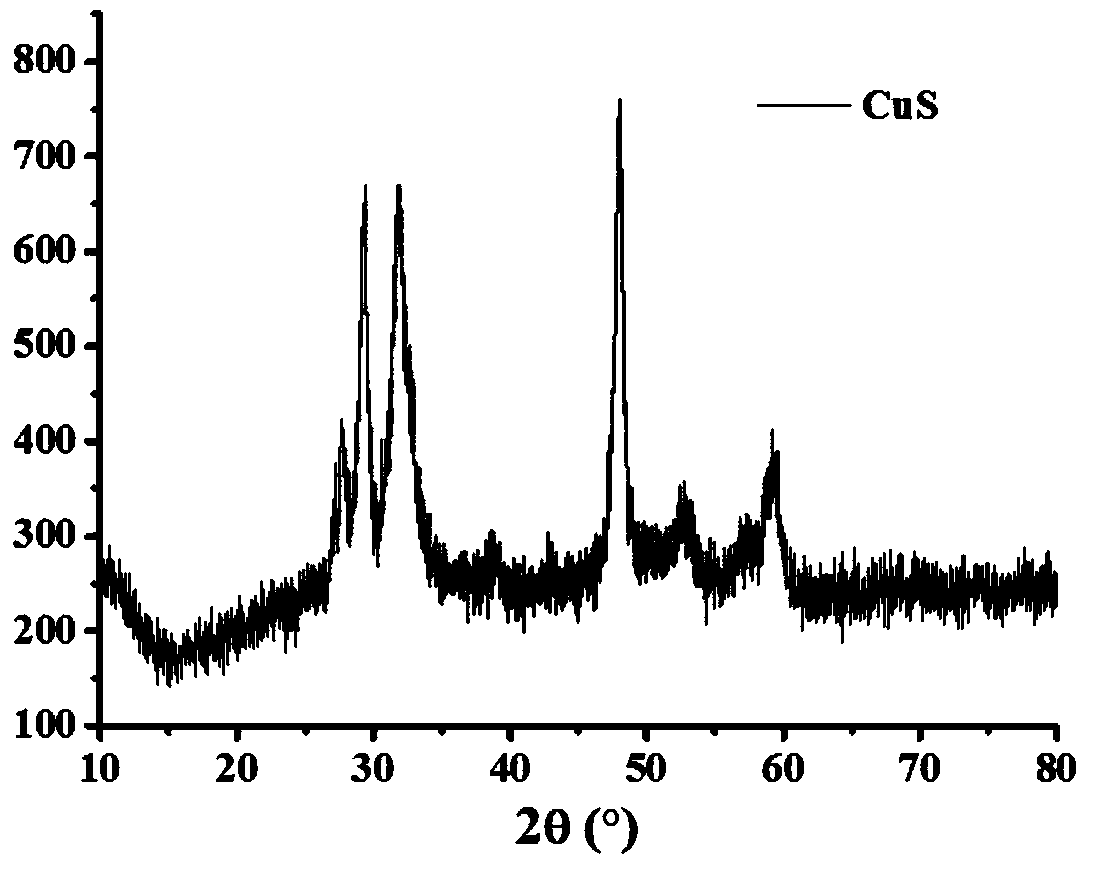

[0092] One, the preparation method of microorganism immobilization agent

[0093] (1) Preparation of biochar: Take the straw, wash it, air dry it, crush it, pass it through a 2mm sieve, and pyrolyze it under anaerobic conditions at 600°C for 2 hours, and then carbonize it; after the carbonized product is naturally cooled, grind it and take 200-400 mesh The retentate between the sieves was treated with 1mol / L hydrochloric acid for 2 hours to remove ash, washed with distilled water until the washing liquid was neutral, and dried at 80°C to obtain biochar.

[0094] (2) Fe 2 o 3 , Fe 3 o 4 load of:

[0095] a: Take 100g of biochar obtained in step (1) and add it to 1L biochar containing 0.3125mol FeCl 3 In the aqueous solution, add NaOH solution again, after stirring for 4h, collect the precipitate; Fe 3+ The molar ratio with NaOH is 1:7;

[0096] b: Wash the precipitate with deionized water for 6 times, mix the precipitate with NaOH solution and place it in a hydrothermal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com