Crucible cover plate for polycrystalline silicon ingot casting

A crucible cover, polycrystalline silicon technology, applied in the direction of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problems of accelerated melt convection, damage to the heater cover, small thermal shock, etc., to improve the thermal shock resistance. performance, improved impact resistance, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

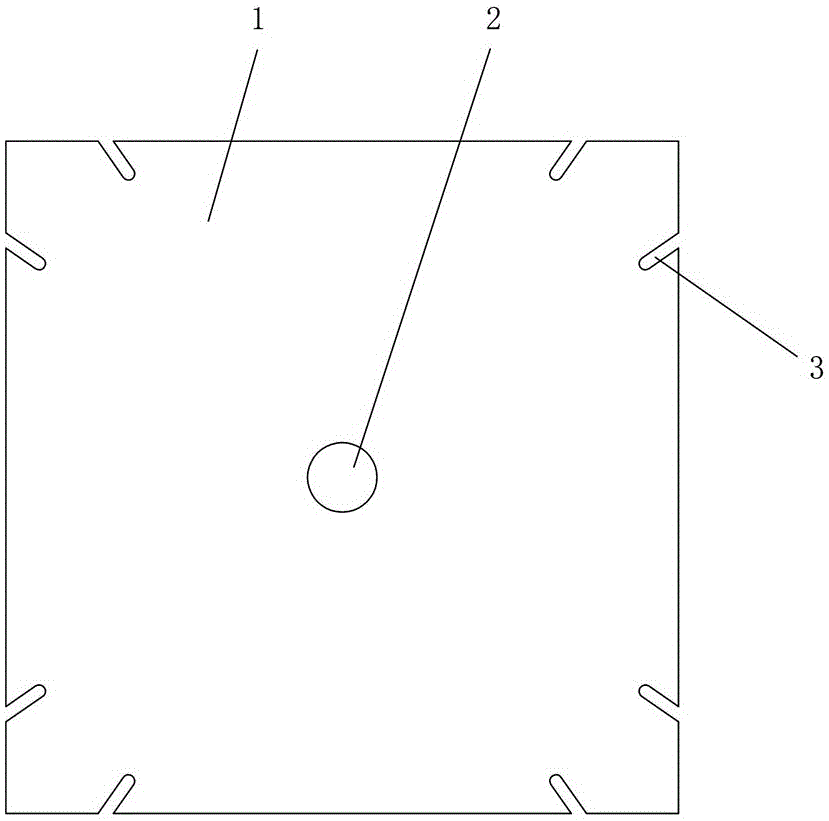

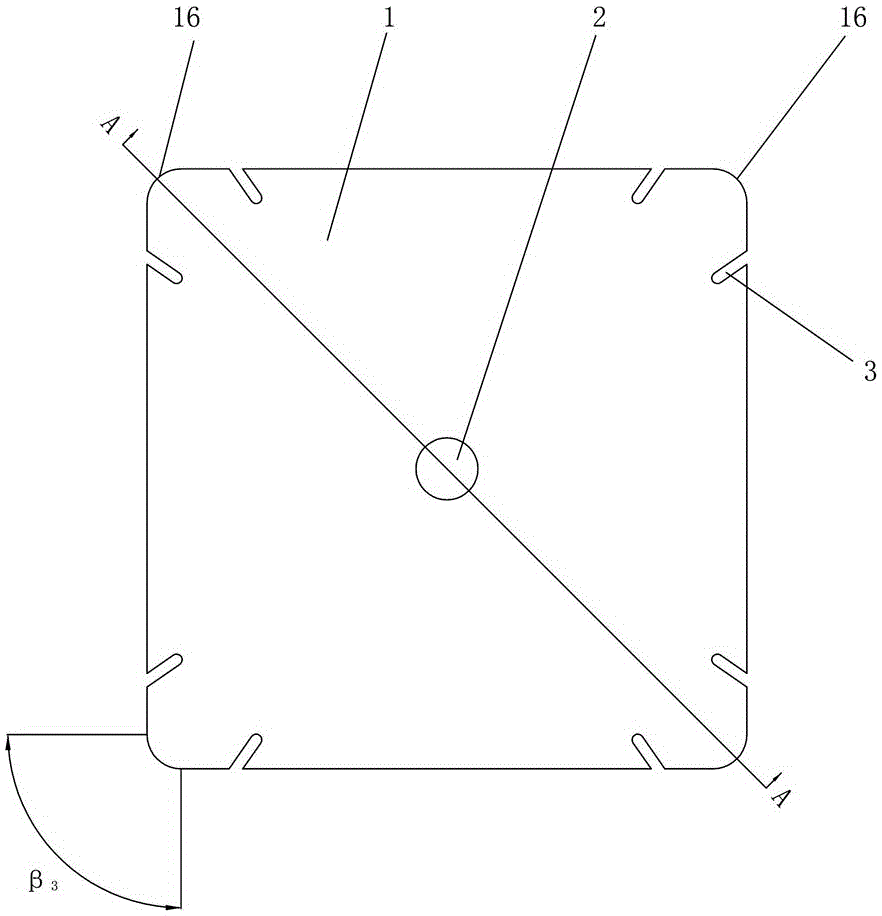

[0031] Such as Figure 3 to Figure 6 As shown, the crucible cover plate for polysilicon ingot in this embodiment includes a cover plate body 1, and a first transition arc surface 13 is provided between the side surface 11 of the cover plate body 1 and the upper surface 12 of the cover plate body 1, and the side surface 11 and the lower surface 14 of the cover body 1 is provided with a second transition arc surface 15, and the central angle corresponding to the first transition arc surface 13 is β 1 , 0°1 2 , 0°2 <180°, the width of the cover body 1 is D, 0mm<D<20mm; the crucible cover plate for polycrystalline silicon ingots has a simple structure, which improves the thermal shock resistance of the section of the cover body 1, and is not prone to corrosion and pulverization or fall off, which improves the quality of the product and prolongs the service life of the cover plate; it also reduces the stress at the section and improves the impact resistance.

[0032] Specific as ...

Embodiment 2

[0037] Specific as Figure 7 As shown, the structure of the crucible cover plate for polysilicon ingot in this embodiment is basically the same as that of Embodiment 1, the difference is that the first transition arc surface 13 and the second transition arc surface 15 are smoothly connected, in this embodiment , β 1 =β 2=90°, and the first transition arc surface 13 and the second transition arc surface 15 form a complete semi-arc surface, and in other embodiments, the transition arc surface can also be additionally set to realize the first transition arc surface 13 and The smooth connection of the second transitional arc surface 15; the structural forms of the fourth transitional arcuate surface 17 and the fifth transitional arcuate surface 18 can remain the same as in Embodiment 1, and can also be the same as the first transitional arc in this embodiment. The surface 13 is the same as the second transition arc surface 15 , that is, the fourth transition arc surface 17 and t...

Embodiment 3

[0039] Specific as Figure 8 As shown, in this embodiment, the third transitional arc surface 16 includes three segments 161, and each segment 161 is smoothly connected sequentially. The structural form of the first transition arc surface 13 and the second transition arc surface 15, the first The structures of the four transition arc surfaces 17 and the fifth transition arc surface 18 are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com