Off-ground treatment technology for waste drilling fluid

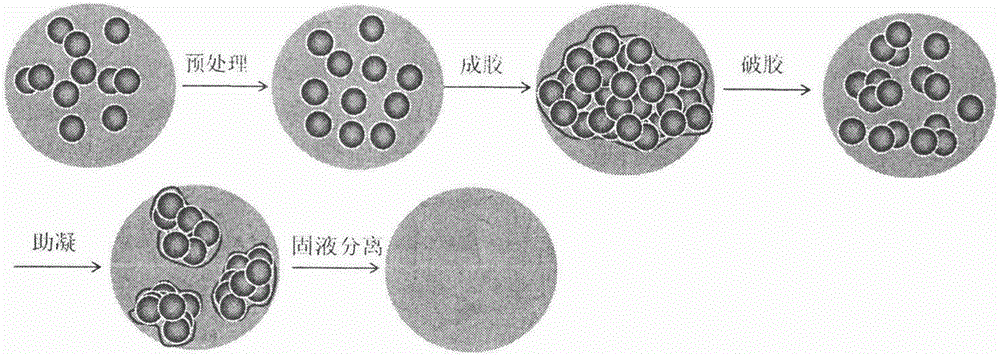

A technology for drilling mud and waste mud, which is applied in sludge treatment, mining wastewater treatment, water/sludge/sewage treatment, etc. It can solve the problems of high operating conditions, high treatment costs, environmental pollution, etc., and solve the treatment costs high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take the oilfield waste drilling water-based mud with a solid content of 44.5% as an example. Take 1000mL of mud, stir at a stirring speed of 200r / min for 20min, then add 70g of polyacrylamide with a concentration of 3%, an appropriate amount of sulfuric acid as an acidulant, 10g of aluminum chloride with a concentration of 3% of an inorganic coagulant and 10g of aluminum chloride with a concentration of 2 % sodium dodecylsulfonate 1g, fully stirred until all the flocs are clustered, and the flocs are centrifuged with a centrifuge at a speed of 2000-3000r / min, and the centrifugation time is 5-10min. The solid content of the mud cake after solid-liquid separation was 85.2%.

Embodiment 2

[0024] Take the oilfield waste drilling water-based mud with a solid content of 24.6% as an example. Take 1000mL of mud and stir for 20min at a stirring speed of 200r / min; then add 45g of polyacrylamide with a concentration of 5%, an appropriate amount of acidulant acetic acid, 15g of calcium chloride with a concentration of 2% of inorganic coagulant aid and 2% of Polyethylene oxide 1g, fully stirred until all flocs are grouped together, and mechanically separated by plate and frame filter press, the separation time is 35min. The solid content of the mud cake after solid-liquid separation is 91.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com