A device detecting NO through chemiluminescence and a detecting method thereof

A chemiluminescence method, chemiluminescence technology, applied in the direction of chemiluminescence/bioluminescence, measurement device, test sample preparation, etc., can solve problems affecting NO measurement, achieve stable NO response value, accurate detection, gas detection tube road stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

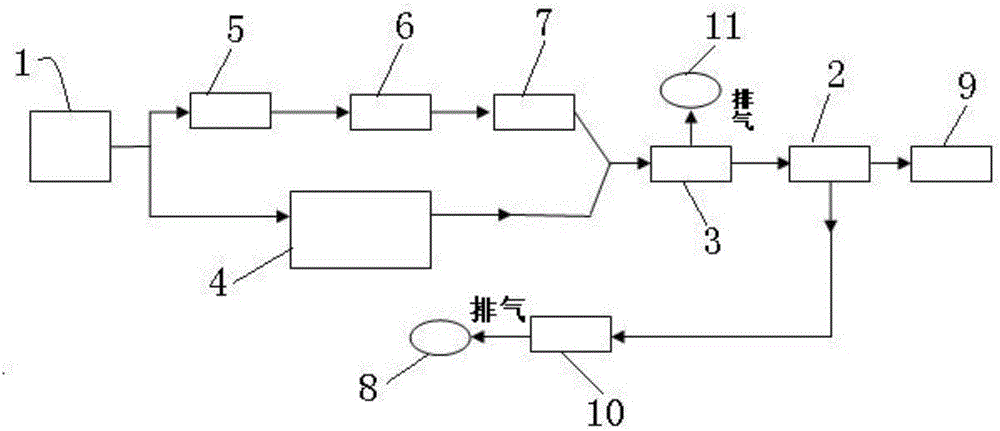

Method used

Image

Examples

Embodiment 1

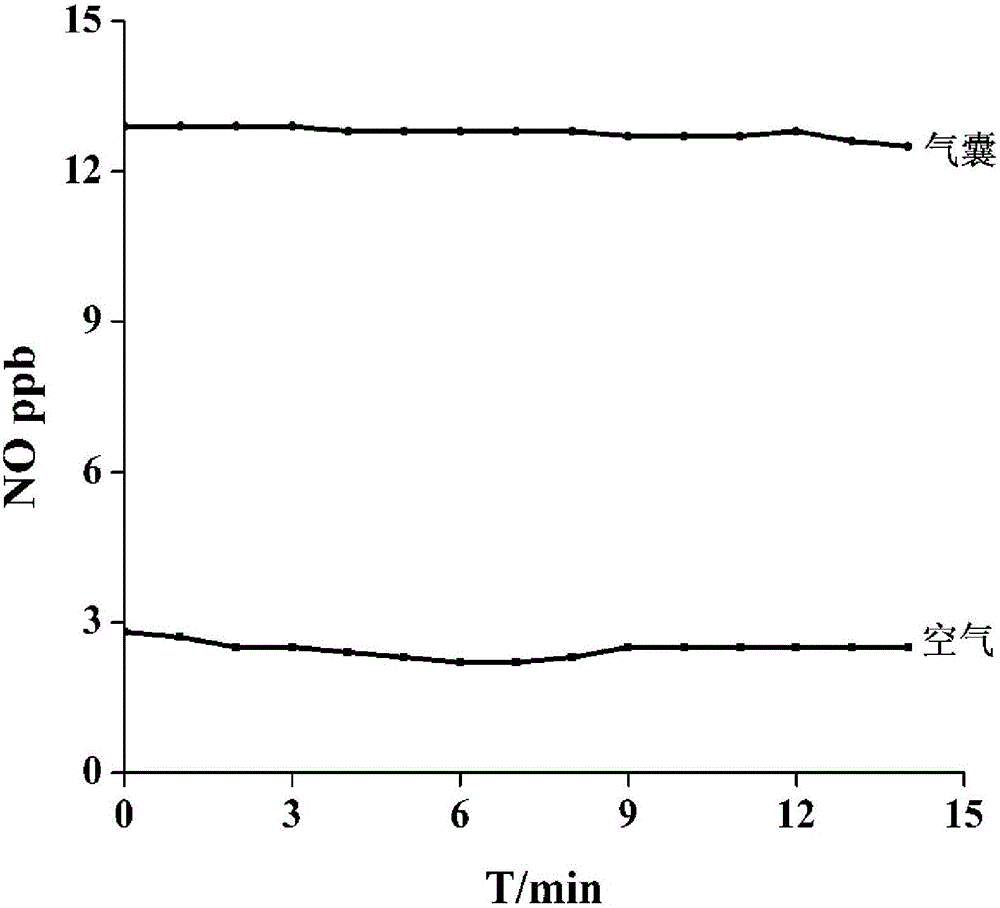

[0044] Example 1. The interference of other gases volatilized from polymer airbags on NO detection

[0045] The nitrogen oxide chemiluminescence analyzer was used as the detector to detect the ambient air and the air filled into the airbag respectively. It was found that the detected value of NO after the air was filled into the airbag made of polyethylene or polyvinyl chloride was much higher than the concentration of NO in the air. , the experimental results are as figure 1 shown. From the experimental results, it can be concluded that other gases volatilized from the polymer airbag interfere with the detection of NO, that is, other gases interfere with the chemiluminescence detection of NO.

Embodiment 2

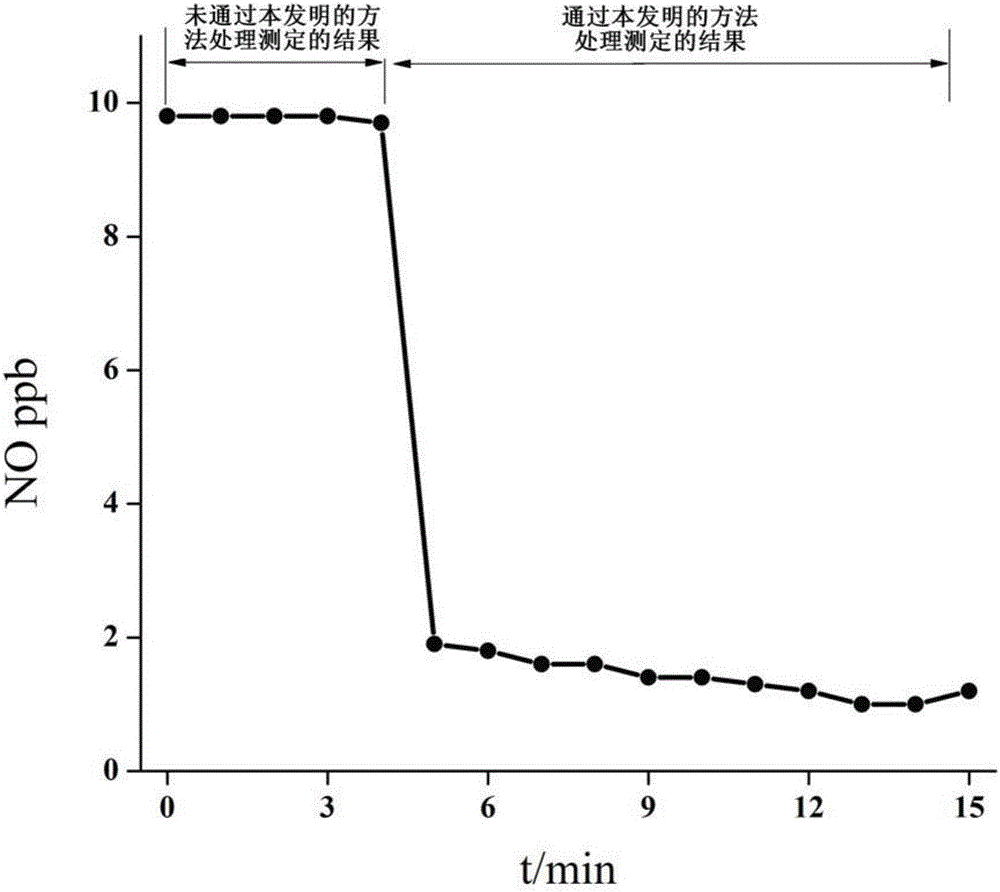

[0046] Example 2. Using NaA molecular sieve membrane to eliminate impurity gas interference and detect NO

[0047] 1) First use high-purity nitrogen to purge the ceramic tube sealing assembly loaded with NaA molecular sieve membrane for 1.5h to activate the NaA molecular sieve membrane. The membrane diameter of the NaA molecular sieve membrane is 0.3nm;

[0048] 2) Then build the pipeline system, and add the activated NaA molecular sieve membrane into the pipeline system, the temperature and relative humidity of the test environment are respectively 25°C and 60%, and the constant temperature and humidity conditions are maintained;

[0049] 3) Open the gas production system and the mass flow control branch, and at the same time close the gas source branch to be detected, adjust the gas production system, and control the gas flow rate of the pipeline system by controlling the mass flow control branch to 700mL / min. The gas in the gas production system is passed into the pipeline ...

Embodiment 3

[0052] Example 3. Utilize hydrophilic modified molecular sieve to eliminate impurities and detect NO

[0053] 1) First activate the hydrophilic modified zeolite molecular sieve in an electric heating constant temperature blast drying oven at a temperature of 100°C for 5 hours;

[0054] 2) Then build a pipeline system, and add 110g of activated hydrophilic modified zeolite molecular sieve into the pipeline system. The temperature and relative humidity of the test environment are respectively 20°C and 80%, and constant temperature and humidity conditions are maintained;

[0055] 3) Open the gas production system and the mass flow control branch, and at the same time close the gas source branch to be detected, adjust the gas production system, and control the gas flow of the pipeline system by controlling the mass flow control branch to 900mL / min. The gas in the gas production system is passed into the pipeline system, the pipeline is purged for 10 minutes, and the nitrogen oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com