RTD diode of indium gallium nitride emitting electrode ohmic contact layer and manufacturing method thereof

An ohmic contact layer and manufacturing method technology, applied in the field of electronics, can solve the problems of In precipitation, reduce output power, large leakage, etc., and achieve the effects of high peak current, large output power, and small leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

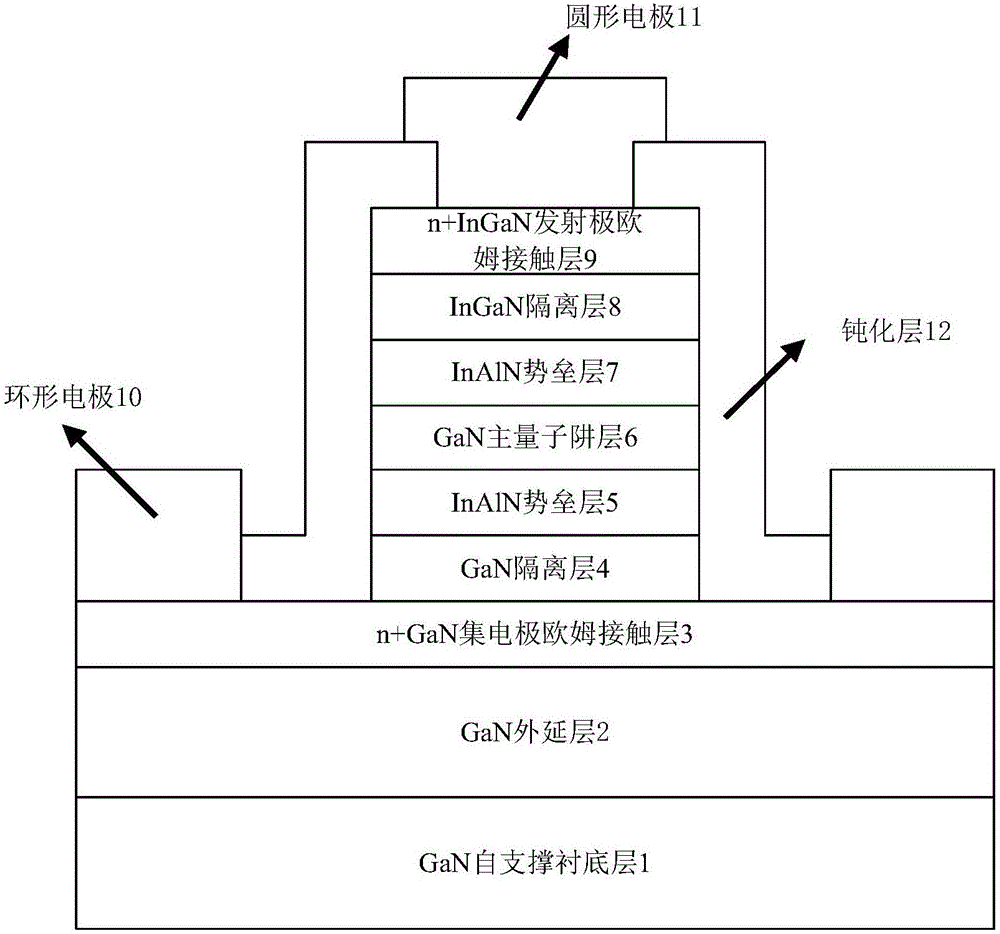

Embodiment 1

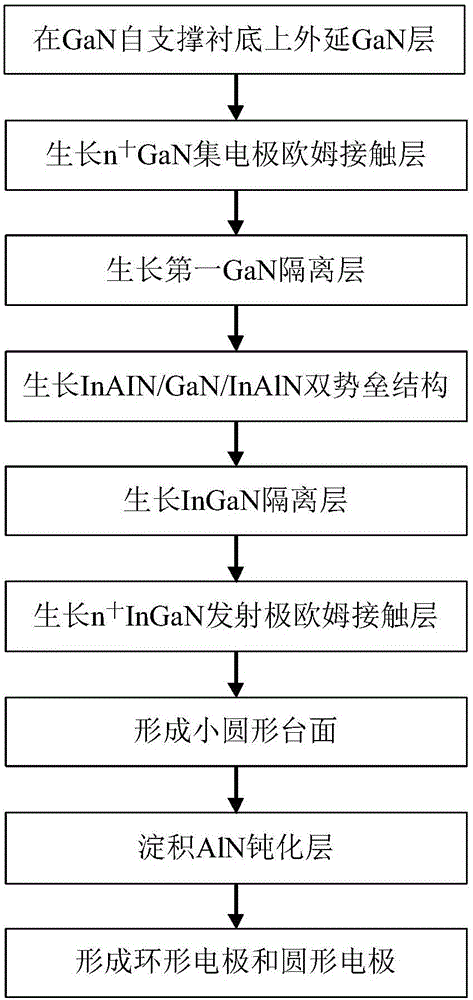

[0113] Example 1: The production thickness is 80nm, the In composition is 3%, and the doping concentration is 1x10 19 n 十 InGaN emitter ohmic contact layer.

[0114] Step 1: Epitaxial GaN layer on GaN free-standing substrate.

[0115] The GaN epitaxial layer 2 is grown on the substrate 1 by the molecular beam epitaxy MBE method.

[0116] The specific steps of the molecular beam epitaxy MBE method are as follows.

[0117] Prepare sources, using high-purity nitrogen and gallium as nitrogen and gallium sources, respectively.

[0118] Put the substrate 1 into the ultra-high vacuum chamber.

[0119] Raise the gallium furnace to a temperature of 850°C.

[0120] The nitrogen source and the gallium source are sprayed from the jet furnace, the flow rate of nitrogen gas is controlled to be 1.6mL / min, the plasma input power is 400W, and the reflected power is 5W.

[0121] Molecular streams ejected by different sources grow GaN layers on the substrate.

[0122] Step 2: Grow n 十 Ga...

Embodiment 2

[0187] Example 2: The production thickness is 100 nm, the In composition is 5%, and the doping concentration is 5×10 19 n 十 InGaN emitter ohmic contact layer.

[0188] Step A: Epitaxial GaN layer on GaN free-standing substrate.

[0189] The GaN epitaxial layer 2 is grown on the substrate 1 by the molecular beam epitaxy MBE method.

[0190] The specific steps of the molecular beam epitaxy MBE method are as follows.

[0191] Prepare sources, using high-purity nitrogen and gallium as nitrogen and gallium sources, respectively.

[0192] Put the substrate 1 into the ultra-high vacuum chamber.

[0193] Raise the gallium furnace to a temperature of 850°C.

[0194] The nitrogen source and the gallium source are sprayed from the jet furnace, the flow rate of nitrogen gas is controlled to be 1.6mL / min, the plasma input power is 400W, and the reflected power is 5W.

[0195] Molecular streams ejected by different sources grow GaN layers on the substrate.

[0196] Step B: Grow n 十 ...

Embodiment 3

[0261] Example 3: The fabrication thickness is 120 nm, the In composition is 7%, and the doping concentration is 1×10 20 n 十 InGaN emitter ohmic contact layer.

[0262] Step 1: Epitaxial GaN layer on GaN free-standing substrate.

[0263] The GaN epitaxial layer 2 is grown on the substrate 1 by the molecular beam epitaxy MBE method.

[0264] The specific steps of the molecular beam epitaxy MBE method are as follows.

[0265] Prepare sources, using high-purity nitrogen and gallium as nitrogen and gallium sources, respectively.

[0266] Put the substrate 1 into the ultra-high vacuum chamber.

[0267] Raise the gallium furnace to a temperature of 850°C.

[0268] The nitrogen source and the gallium source are sprayed from the jet furnace, the flow rate of nitrogen gas is controlled to be 1.6mL / min, the plasma input power is 400W, and the reflected power is 5W.

[0269] Molecular streams ejected by different sources grow GaN layers on the substrate.

[0270] Step 2: Grow n 十...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com