Integrated system based on film generating, energy storage and luminescence

An integrated system and thin film technology, which is applied in the field of new energy development and application, can solve the problems of high energy consumption in the preparation process, high manufacturing cost, inflexibility of inorganic solar devices, etc., and achieve the effect of avoiding the loss of light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

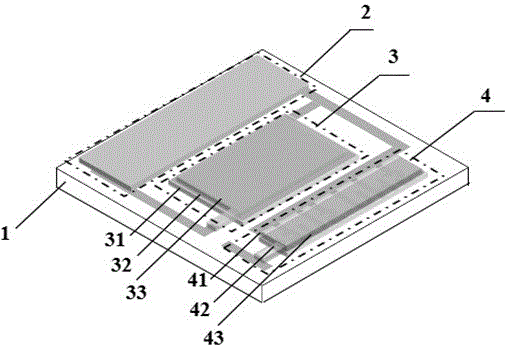

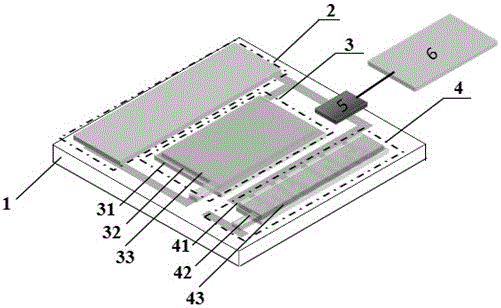

[0022] refer to figure 1 , an integrated system based on thin film power generation, energy storage, and light emission, including: substrate (1), capacitor (2), OPV device (3), super and OLED light emitting device (4). It is characterized in that: the substrate (1), the supercapacitor (2), the OPV device (3) and the OLED light-emitting device (4) are integrated on the same plane of the same substrate.

Embodiment 2

[0024] This embodiment is basically the same as Embodiment 1, and the special features are as follows: the substrate (1) is a glass substrate or a PET flexible substrate. The OPV device (3) uses thin-film technology, and the substrate (1) is sequentially composed of an OPV anode (31), an OPV organic functional layer (32), and an OPV cathode (33) from inside to outside. The OPV device (3) selects one or more of ITO, ZnO, FTO, GZO, graphene, and graphene / carbon nanotube composite film as a transparent anode, and selects one of Au / Ag alloy, Al, and ITO One or more as a transparent or translucent cathode. The supercapacitor (2) uses thin film technology, which is made by inkjet printing, printing and other processes. The OLED light-emitting device (4) uses thin-film technology, and consists of an OLED anode (41), an OLED organic functional layer (42), and an OLED cathode (43) sequentially from the inside to the outside of the substrate. The OLED light-emitting device (4) is a fl...

Embodiment 3

[0026] In this example, see figure 1 , an integrated system based on thin film power generation, energy storage, and light emission, including a glass substrate (1), a supercapacitor (2), an OPV device (3), an OPV anode (31), an OPV organic functional layer (32), and an OPV cathode (33), OLED light-emitting device (4), OLED anode (41), OLED organic functional layer (42), OLED cathode (43).

[0027] In this embodiment, an integrated system based on thin-film power generation, energy storage, and light emission includes: a substrate, an OPV device on the same plane as the substrate, an OLED light-emitting device, and a supercapacitor connecting the OPV device and the OLED light-emitting device. The OPV device adopts an upright structure, from the inside to the outside of the substrate, there are OPV anode, OPV organic functional layer, and OPV cathode. The OLED light-emitting device adopts a bottom emission structure, and the OPV device and OLED light-emitting device adopt a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com