Adjustable picosecond laser

A laser and naughty technology, applied in the laser field, can solve problems such as low output power spontaneous radiation of oscillators, degradation of pulse signal-to-noise ratio, etc., achieve high average power and meet application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

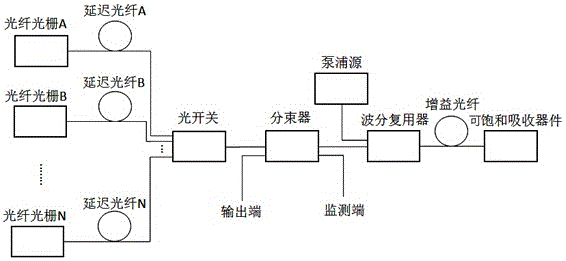

[0012] like figure 1 Shown is a schematic diagram of the structure of a tunable picosecond laser. The tunable picosecond laser is composed of all polarization-maintaining fiber devices connected in sequence, and a saturable absorber is used to achieve passive mode locking. One end of the laser is a saturable absorption device, and then a gain fiber, a wavelength division multiplexer, a beam splitter, an optical switch, several delay fibers and corresponding fiber gratings connected to the delay fibers one by one are sequentially connected. The other input port of the wavelength division multiplexer is connected with a pump source. The other two ports of the beam splitter are used as the output end and the monitoring end respectively.

[0013] The output wavelength of the tunable picosecond laser is determined by the parameters selected by the optical switch and the reflection wavelength of the fiber grating oscillated by the laser. The pulse width is determined by the parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com