Tricholoma matsutake tofu and method thereof

A technology of matsutake and tofu, which is applied in the field of food processing and matsutake tofu, which can solve the problems of insufficient nutrients and achieve the effects of improving texture and taste, helping digestion, and enhancing human immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

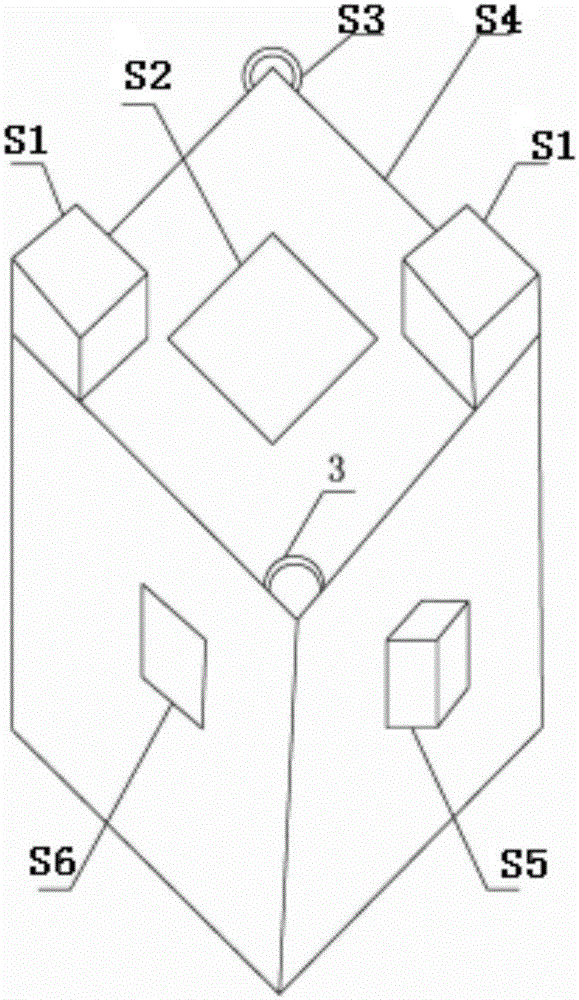

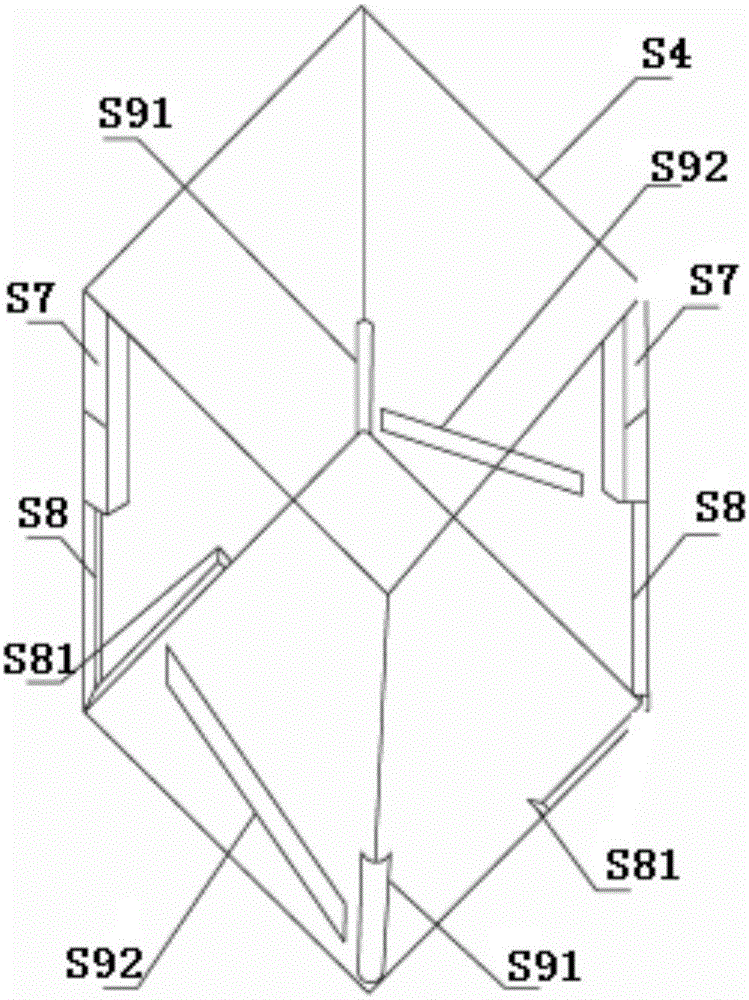

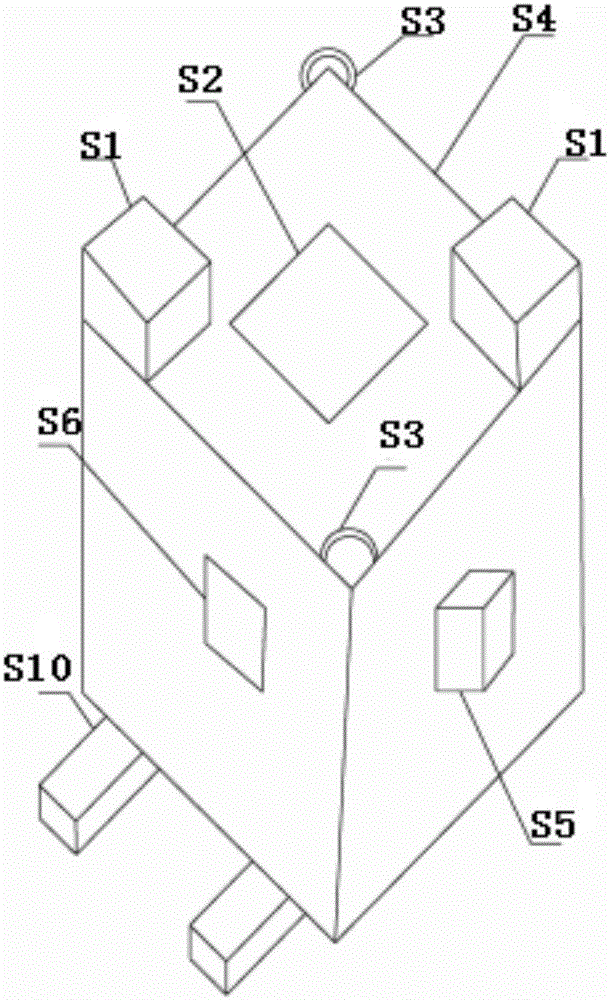

Image

Examples

Embodiment 1

[0044] The preparation method of matsutake tofu comprises the following steps:

[0045] (1) Take fresh matsutake and clean it; put it into a drying oven and bake at 40°C for 5 hours; send the dried matsutake into a grinder for crushing, and then put the crushed Matsutake is passed through a 80-mesh sieve to obtain matsutake powder;

[0046] (2) Add the matsutake powder obtained in step (1) into water and ferment for 2 hours, then add edible salt, starch, I+G, white granulated sugar, yeast powder and natamycin to it, and stir evenly to obtain a seasoning slurry;

[0047] (3) Chopping and emulsifying soy protein isolate and water for 10 minutes, then adding edible oil and TG enzyme to it to emulsify into a slurry, continuing to add soybean textured protein and the seasoning slurry obtained in step (2), and stirring until completely emulsified To obtain an emulsion, wherein the emulsification temperature is 10° C.; the emulsification pH value is 6;

[0048] (4) Add the emulsion...

Embodiment 2

[0054] The preparation method of matsutake tofu comprises the following steps:

[0055] (1) Take fresh matsutake and clean it; put it into a drying oven and bake at a temperature of 50°C for 7 hours; send the dried matsutake into a grinder for crushing, and then put the crushed Matsutake is passed through a 100-mesh sieve to obtain matsutake powder;

[0056] (2) adding the matsutake powder obtained in step (1) into water and fermenting for 2.5 hours, then adding edible salt, starch, I+G, white granulated sugar, yeast powder and natamycin to it, and stirring evenly to obtain a seasoning slurry;

[0057] (3) Chopping and emulsifying soy protein isolate and water for 13 minutes, then adding edible oil and TG enzyme to it to emulsify into a slurry, continuing to add soybean textured protein and the seasoning slurry obtained in step (2), and stirring until completely emulsified To obtain an emulsion, wherein the emulsification temperature is 30° C.; the emulsification pH value is ...

Embodiment 3

[0064] The preparation method of matsutake tofu comprises the following steps:

[0065] (1) Take fresh matsutake and clean it; put it into a drying box and bake at 60°C for 8 hours; send the dried matsutake into a grinder for crushing, and then put the crushed Matsutake is passed through a 120-mesh sieve to obtain matsutake powder;

[0066] (2) adding the matsutake powder obtained in step (1) into water and fermenting for 3 hours, then adding edible salt, starch, I+G, white granulated sugar, yeast powder and natamycin to it, and stirring evenly to obtain a seasoning slurry;

[0067] (3) Chop and emulsify the soybean protein isolate and water for 15 minutes, then add edible oil and TG enzyme to it to emulsify into a slurry, continue to add soybean textured protein, the seasoning slurry obtained in step (2), and stir until completely emulsified To obtain an emulsion, wherein the emulsification temperature is 50° C.; the emulsification pH value is 7;

[0068] (4) the emulsion t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com