Reaction kettle for phenyl chloroformate

A technology of phenyl chloroformate and reactors, which is applied in the field of reactors, can solve problems such as reducing the service life of reactors, uneven heating of materials, and affecting product quality, so as to avoid excessive local temperature, speed up the reaction process, and prevent side effects. The effect of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

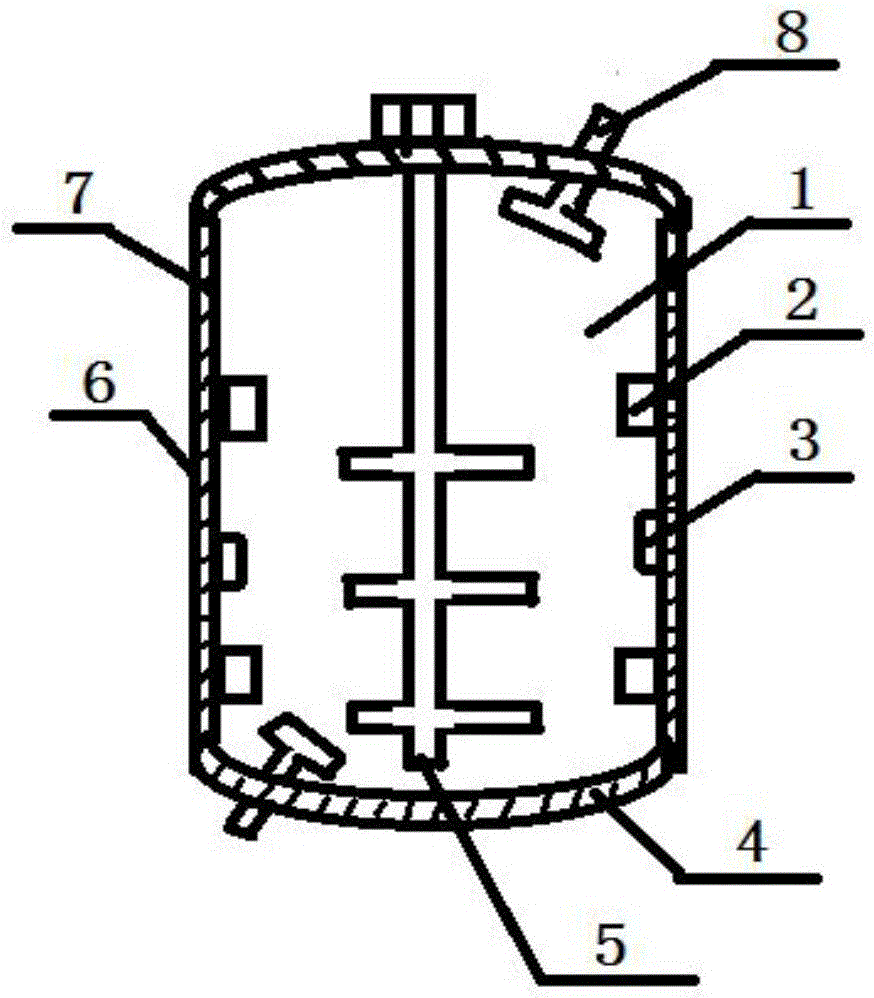

[0015] A reaction kettle for phenyl chloroformate, comprising a reaction kettle body 1, a heating device 2, a temperature measuring device 3, a stirrer 5, and a fan 8. The reaction kettle body 1 is cylindrical, and the heating device 2 There are four, which are located on the left and right walls of the reactor, and are symmetrical to each other; the outer wall of the reactor is coated with a thermal insulation coating 6, which has a weight ratio of 2:1:3 : 2:1 diatomaceous earth, calcium silicate, perlite, foamed concrete and red phosphorus thermal insulation materials are mixed uniformly, then mixed into a solution, and then loaded into the spray gun for spraying; the inner wall of the reactor is coated with high temperature anticorrosive coating Layer 7, high temperature resistant and anticorrosive coating 7 is made by mixing quartz sand, clay, and nano-polyphenylene sulfide powder with a weight ratio of 1:1:3, then ultrasonic water dissolution, viscosity adjustment, and dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com