Method for preparing TiO2/g-C3N4 quantum dot composite catalyst

A composite catalyst and titanium dioxide technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of high catalytic efficiency, simple preparation process, and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Use a graduated cylinder to measure 35mL of absolute ethanol into a clean beaker A, slowly add 10mL of n-butyl titanate under strong stirring, and then stir vigorously for 20 minutes to obtain a mixed solution of ethanol and tetra-n-butyl titanate a.

[0018] 2) Measure 35mL of absolute ethanol into a clean beaker B, add 4mL of glacial acetic acid and 10mL of deionized water into the beaker of B, and stir vigorously for 20min to obtain a mixed solution B of ethanol, glacial acetic acid and deionized water. Add an appropriate amount of concentrated hydrochloric acid dropwise to adjust the pH.

[0019] 3) Place beaker B in a water bath at 25°C and stir vigorously, suspend solution A and slowly drop into beaker B.

[0020] 4) After the dropwise addition, continue to stir at a low speed until a gel is formed. And stand in a 40°C water bath until the gel is complete

[0021] 5) Dry the obtained gel at 80°C for 12 hours. The dried samples were ground.

[0022] 6) Calc...

Embodiment 2

[0028] In step (7), add 98ml deionized water, and in step (8), add g-C 3 N 4 Quantum dot solution 2ml, other steps are the same as in Example 1.

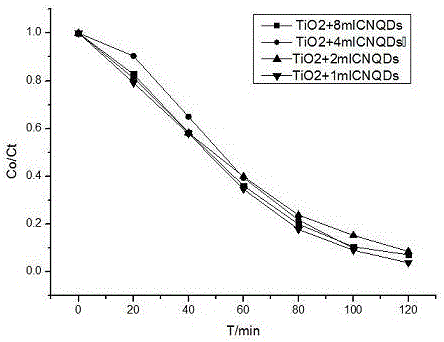

[0029] The resulting product is TiO 2 -CNQDs2.0ml, used to degrade 50ml, 10PPm methyl orange solution under simulated sunlight, after 100min, the degradation rate reached 90.15%.

Embodiment 3

[0031] In step (7), 96ml of deionized water was added, and in step (8), 4ml of g-C3N4 quantum dot solution was added, and other steps were the same as in Example 1.

[0032] The resulting product is TiO 2 -CNQDs4.0ml was used to degrade 50ml 10PPm methyl orange solution under simulated sunlight, and the degradation rate reached 91.38% after 120min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com