Preparation method and use of cadmium sulfide-immobilized tetra(4-carboxyphenyl)ferriporphyrin catalysis material

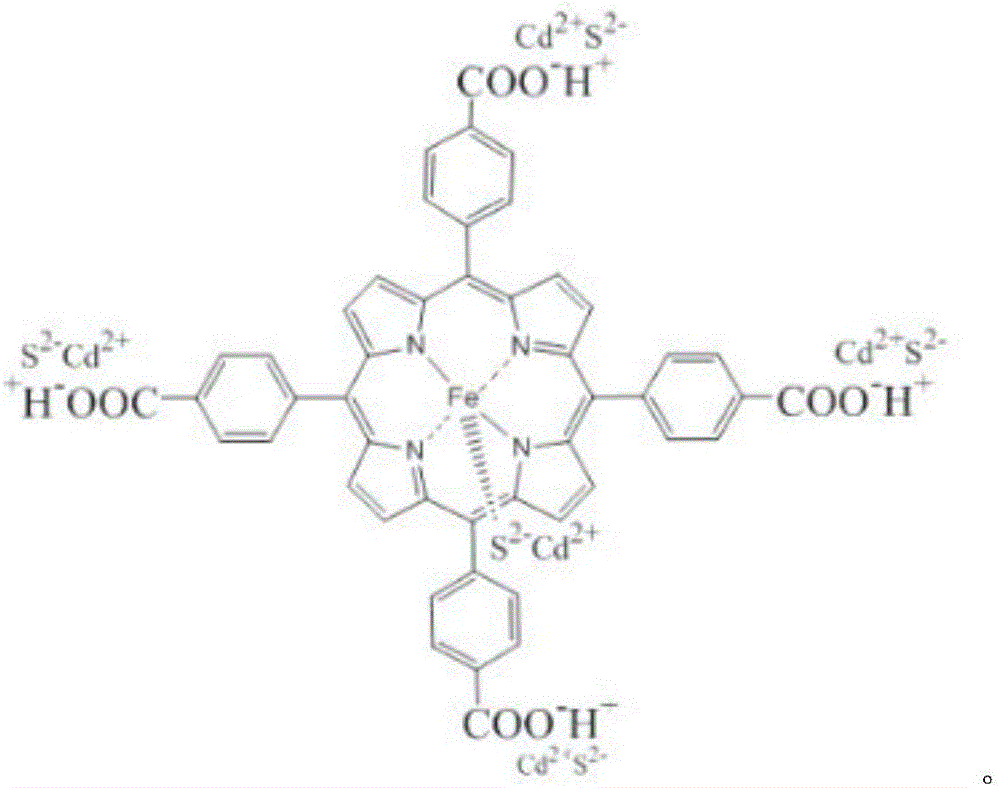

A porphyrin catalytic material, carboxyphenyl technology, applied in the field of preparation of cadmium sulfide-immobilized tetrairon porphyrin catalytic material, can solve the problems of no significant reduction in catalytic efficiency, low catalytic efficiency of metalloporphyrin, and many times of repeated use , to achieve the effects of less metalloporphyrin dosage, improved metalloporphyrin performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

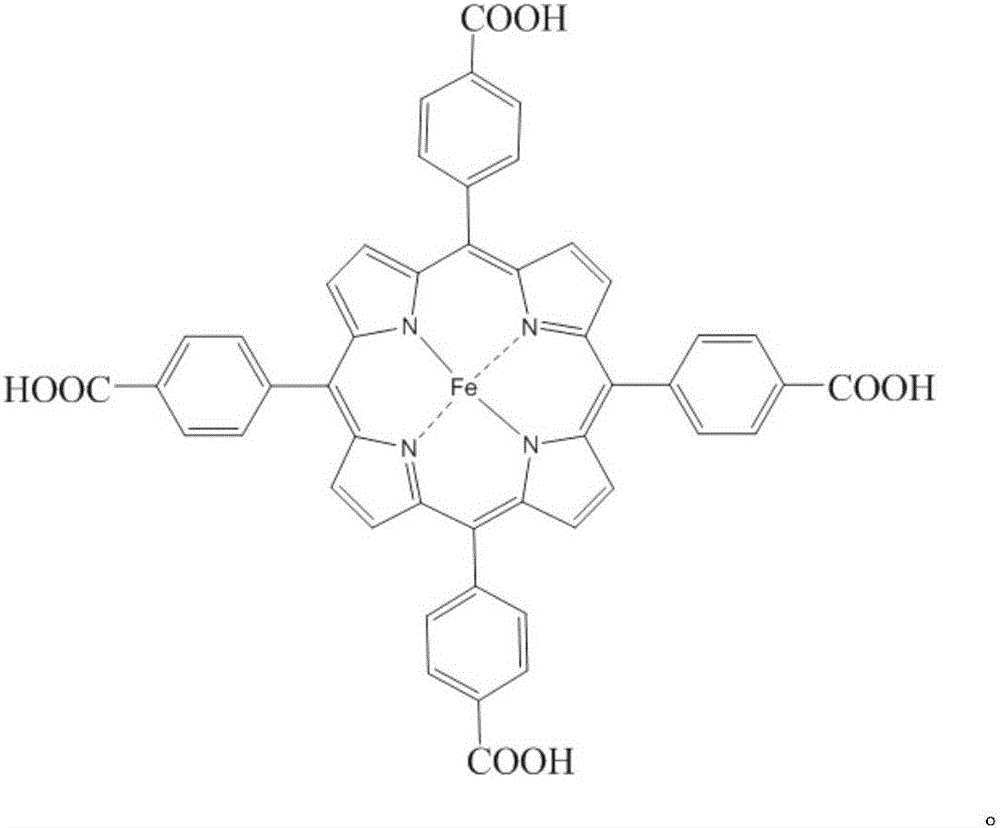

[0026] A cadmium sulfide immobilized tetrakis (4-carboxyphenyl) iron porphyrin catalytic material is composed of the following raw materials in parts by weight: 124 parts of cadmium nitrate tetrahydrate, 30 parts of thioacetamide, 1780 parts of ethylene glycol, tetra( 0.030 parts of 4-carboxyphenyl) iron porphyrin, 240 parts of absolute ethanol, 118 parts of cyclohexane and 200 parts of deionized water.

[0027] The preparation method of described cadmium sulfide immobilized tetrakis (4-carboxyphenyl) iron porphyrin catalytic material comprises the following steps:

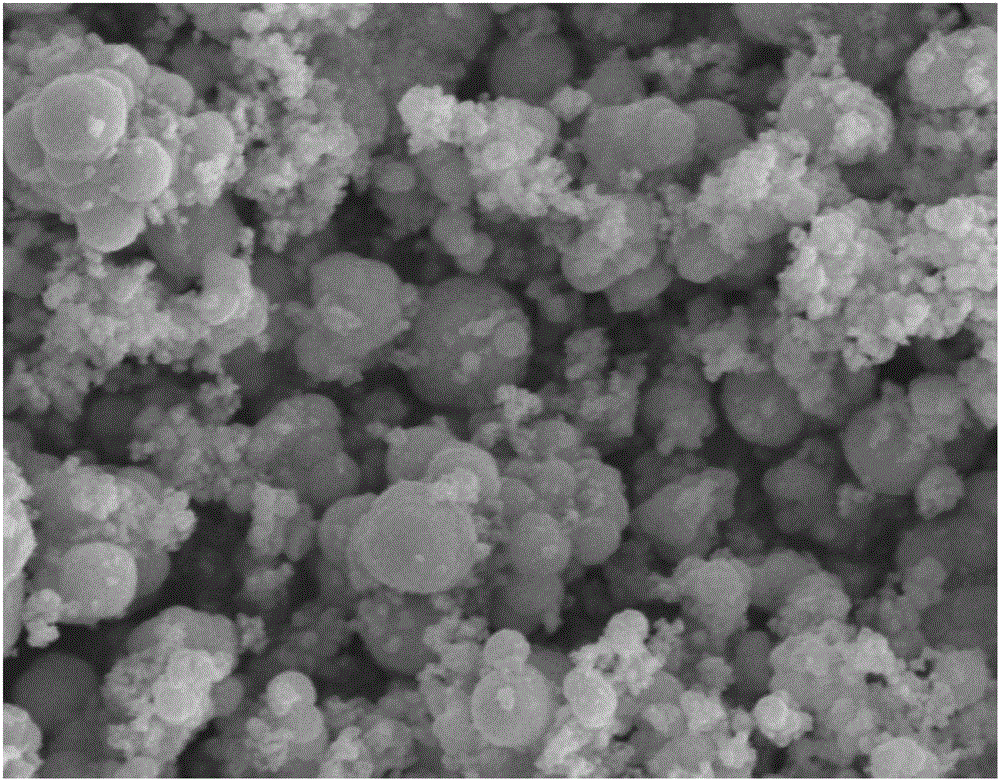

[0028] (1) Preparation of cadmium sulfide: Weigh 124 parts of cadmium nitrate tetrahydrate and 30 parts of thioacetamide respectively, dissolve them in 1780 parts of ethylene glycol, stir magnetically for 4 minutes, heat with microwave for 20 seconds, stop 60s, reheated for 20s, stopped for 60s, repeated heating cycle 19 times, cooled naturally to room temperature, put it in a centrifuge with a rotating speed of 9...

Embodiment 2

[0034] A cadmium sulfide immobilized tetrakis (4-carboxyphenyl) iron porphyrin catalytic material is composed of the following raw materials in parts by weight: 123 parts of cadmium nitrate tetrahydrate, 31 parts of thioacetamide, 1778 parts of ethylene glycol, tetra( 0.032 parts of 4-carboxyphenyl) iron porphyrin, 254 parts of absolute ethanol, 116 parts of cyclohexane and 210 parts of deionized water.

[0035] The preparation method of described cadmium sulfide immobilized tetrakis (4-carboxyphenyl) iron porphyrin catalytic material comprises the following steps:

[0036] (1) Preparation of cadmium sulfide: Weigh 123 parts of cadmium nitrate tetrahydrate and 31 parts of thioacetamide respectively, dissolve them in 1778 parts of ethylene glycol, stir magnetically for 3 minutes, heat with microwave for 21 seconds, stop 61s, reheat for 21s, stop for 61s, and repeat the heating cycle for 18 times, naturally cool to room temperature, put it into a centrifuge with a rotation speed...

Embodiment 3

[0041] A cadmium sulfide immobilized tetrakis(4-carboxyphenyl)iron porphyrin catalytic material is composed of the following raw materials in parts by weight: 125 parts of cadmium nitrate tetrahydrate, 32 parts of thioacetamide, 1779 parts of ethylene glycol, tetra( 0.031 parts of 4-carboxyphenyl) iron porphyrin, 247 parts of absolute ethanol, 120 parts of cyclohexane and 205 parts of deionized water.

[0042] The preparation method of described cadmium sulfide immobilized tetrakis (4-carboxyphenyl) iron porphyrin catalytic material comprises the following steps:

[0043] (1) Preparation of cadmium sulfide: Weigh 125 parts of cadmium nitrate tetrahydrate and 32 parts of thioacetamide respectively, dissolve them in 1779 parts of ethylene glycol, stir magnetically for 5 minutes, heat with microwave for 22 seconds, stop 62s, reheat for 22s, stop for 62s, repeat the heating cycle for 20 times, cool down to room temperature naturally, put it in a centrifuge with a rotation speed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com