Manufacturing method of middle density fiberboard for enhancing board soundproof effect

A production method and medium density technology, applied in the field of building materials, can solve the problems of backward application technology and narrow application field, and achieve the effect of reducing noise pollution, improving sound insulation effect, improving production level and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

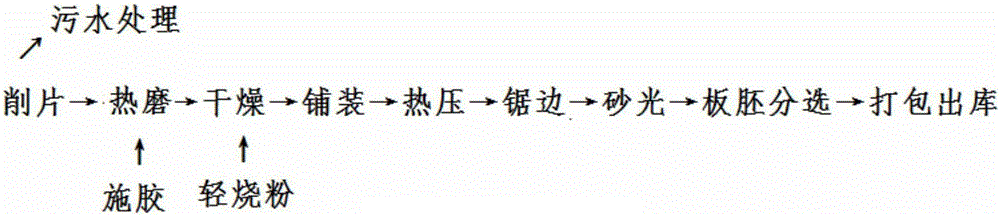

[0030] Process flow of the present invention such as figure 1 Shown, the present invention is specifically described below according to accompanying drawing;

[0031] (1) Definition of glass wool:

[0032] Glass wool is a category of glass fiber and is a man-made inorganic fiber. Natural ores such as quartz sand, limestone, dolomite are used as main raw materials, and some chemical raw materials such as soda ash and borax are used to melt into glass. In the melted state, it is blown into floc fine fibers with the help of external force. In addition to maintaining the unique characteristics of heat preservation and heat insulation, it also has excellent fire prevention, shock absorption and sound absorption characteristics, which is conducive to reducing noise pollution and improving the working environment.

[0033] (2) main component of the present invention (by weight fraction ratio)

[0034] name

effect

scale range

wood fiber

Substrate

85...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com