Heavy metal adsorbent and preparation method and application thereof

A heavy metal and adsorbent technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, special forms of dry distillation, etc., can solve problems such as limited treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

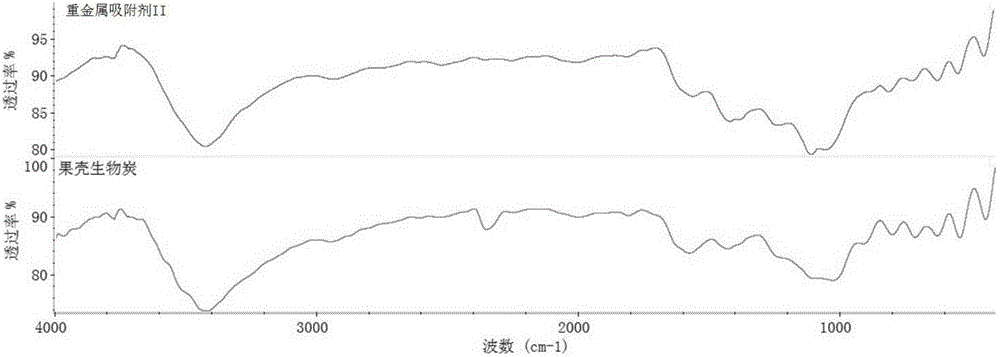

[0022] The discarded mustard collected from the vegetable market was air-dried naturally, and biochar was prepared by pyrolysis under the protection of nitrogen. The equipment used was a tubular muffle furnace. The pyrolysis temperature control program was as follows: 1. Increase the temperature from room temperature to 350°C, ② keep the temperature at 350°C for 30 minutes, ③ increase the temperature from 350°C to 650°C at a heating rate of 500°C / h, ④ keep the temperature at 650°C for 120 minutes, and ⑤ cool down naturally; use a ball mill to grind the fired biochar until the particle size is less than 1 micron, to obtain the heavy metal adsorbent I.

Embodiment 2

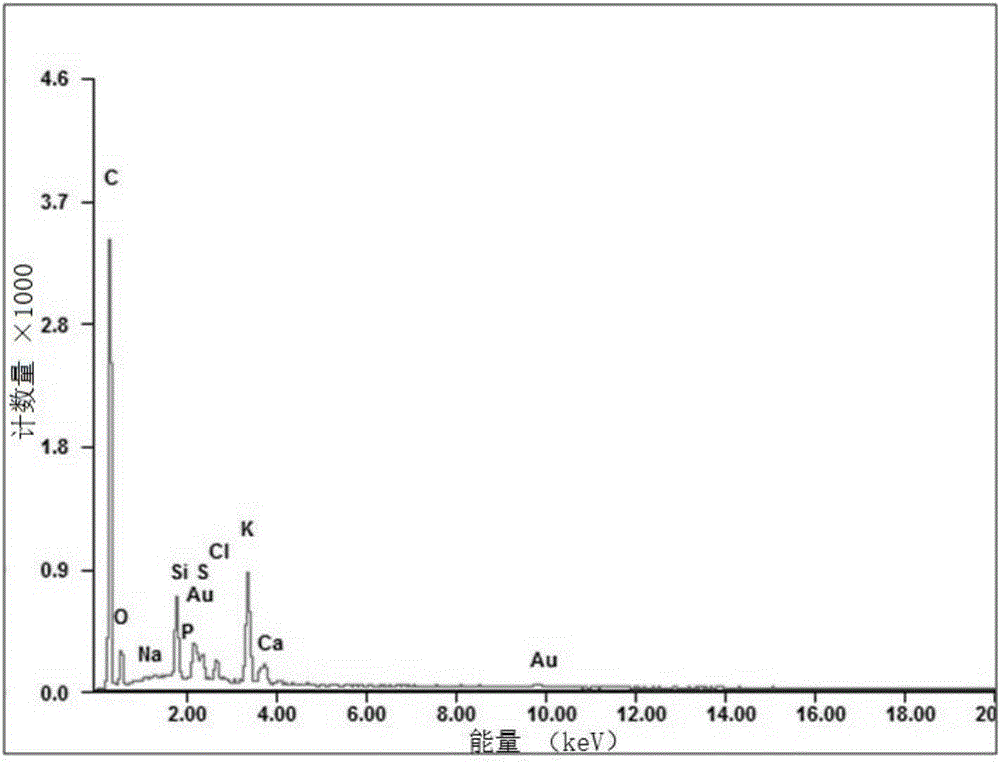

[0024] The discarded rapeseed will be collected and air-dried naturally, and the air-dried rapeseed will be pyrolyzed under the protection of nitrogen to prepare biochar. The equipment used is a tubular muffle furnace. The pyrolysis temperature control program is: 1. The temperature was raised from room temperature to 350°C, ②at 350°C for 30 minutes, ③at a heating rate of 500°C / h from 350°C to 650°C, ④at 650°C for 120 minutes, and ⑤naturally cooling down; If the diameter is less than 1 micron, the heavy metal adsorbent II is obtained.

Embodiment 3

[0026] The discarded cabbage will be collected and air-dried naturally, and the air-dried cabbage will be pyrolyzed under the protection of nitrogen to prepare biochar. The equipment used is a tubular muffle furnace. The pyrolysis temperature control program is: 1. Raise the temperature from room temperature to 400°C, ② keep the temperature at 400°C for 20 minutes, ③ raise the temperature from 400°C to 600°C at a heating rate of 300°C / h, ④ keep the temperature at 600°C for 180 minutes, and ⑤ cool down naturally; If the diameter is less than 1 micron, the heavy metal adsorbent III is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com