Method for preparing ordered mesoporous strontium titanate

A strontium titanate and mesoporous technology, applied in the field of preparation of ordered mesoporous strontium titanate, can solve the problems of low specific surface area and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the ordered mesoporous strontium titanate of the present invention comprises the following steps:

[0021] (1), dissolve the surfactant in absolute ethanol, stir to form a transparent solution; then dropwise add the ethanol solution of the phenolic resin, the amount of the phenolic resin corresponding to every 1g of the surfactant ranges from 1 to 1.5g, stir uniform, spare;

[0022] (2) Adjust the pH of absolute ethanol to <1 with HCl solution, then add tetra-n-butyl titanate and strontium acetate, and stir to obtain a solution; set aside;

[0023] (3), add the solution obtained in step (2) dropwise to the solution obtained in step (1), the amount of tetra-n-butyl titanate corresponding to 1g of surfactant is in the range of 1.5-2g, stir to make it Mix well to obtain an orange solution;

[0024] (4) Transfer the solution prepared in step (3) to a flat-bottomed container, conduct solvent evaporation at 25° C. to induce self-assembly for at lea...

Embodiment 1

[0033] (1) 1g polyoxyethylene / polyoxypropylene / polyoxyethylene amphiphilic block copolymer F127 (purchased from Sigma-Aldrich Company) and 1.25g phenolic resin ethanol solution (phenolic resin mass fraction 20%) were dissolved in 6ml In absolute ethanol, stir for 1 h to form a transparent solution A;

[0034] (2) Add 1ml of concentrated HCl solution (10mol / L) to 3ml of absolute ethanol, adjust the pH<1, then slowly add 1.7g of tetra-n-butyl titanate and 1.05g of strontium acetate, and magnetically stir to obtain a transparent solution B;

[0035] (3) Then add solution B to solution A dropwise, stir for 1 h to make it evenly mixed, thereby obtaining an orange-yellow solution;

[0036] (4) Transfer the orange-yellow solution to a flat-bottomed container, induce self-assembly by solvent evaporation at 25°C for 24h, and then thermally polymerize at 100°C for 12h to form an orange-yellow film;

[0037] (4) Put the orange-yellow film into a porcelain boat, heat-treat it in an atmo...

Embodiment 2

[0041] (1) 1g polyoxyethylene / polyoxypropylene / polyoxyethylene amphiphilic block copolymer F127 (purchased from Sigma-Aldrich Company) and 1g ethanol solution of phenolic resin (phenolic resin mass fraction 20%) were dissolved in 6ml without In water and ethanol, stir for 1 hour to form a transparent solution A;

[0042] (2) Add 1ml of concentrated HCl solution (10mol / L) to 3ml of absolute ethanol, adjust the pH<1, then slowly add 2g of tetra-n-butyl titanate and 1.24g of strontium acetate, and magnetically stir to obtain a transparent solution B ;

[0043] (3) Then add solution B to solution A dropwise, stir for 1 h to make it evenly mixed, thereby obtaining an orange-yellow solution;

[0044] (4) Transfer the orange-yellow solution to a flat-bottomed container, induce self-assembly by solvent evaporation at 25°C for 24h, and then thermally polymerize at 80°C for 24h to form an orange-yellow film;

[0045] (4) Put the orange-yellow film into a porcelain boat, heat-treat it in...

PUM

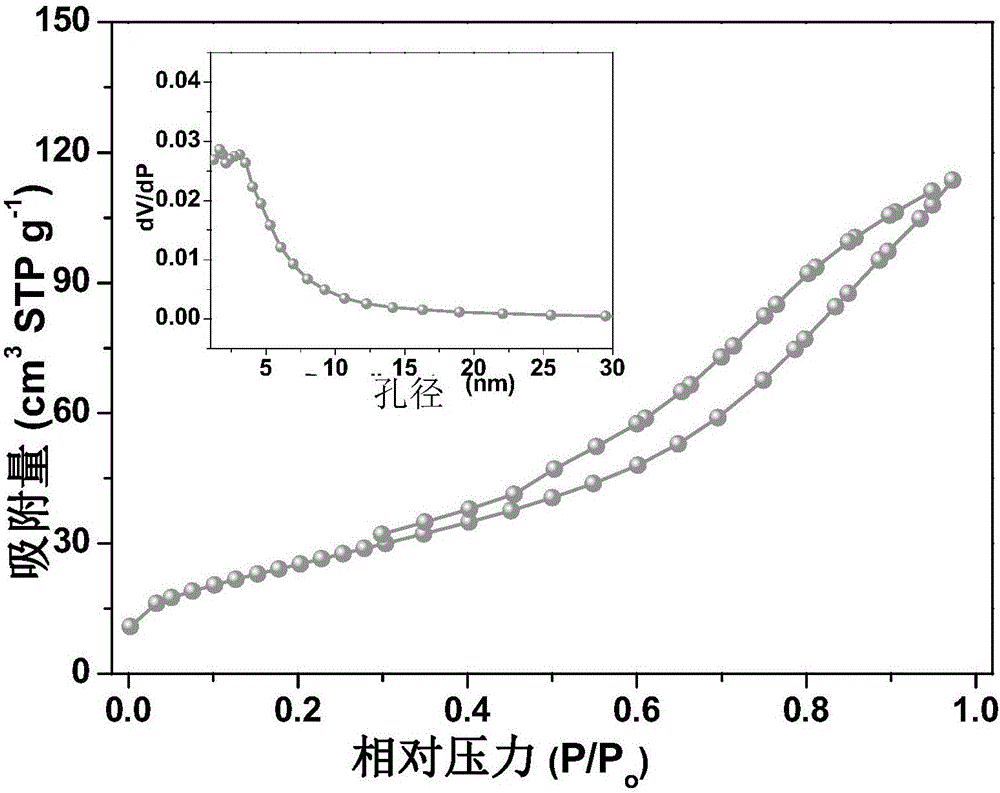

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com