A kind of production technology of polyglycerol fatty acid ester

A technology of fatty acid ester and polyglycerin, which is applied in the field of emulsifier preparation, can solve the problems of imperfect manufacturing technology, poor product quality, high production cost, etc., and achieve the effects of avoiding residue and side effects, improving color and rational structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

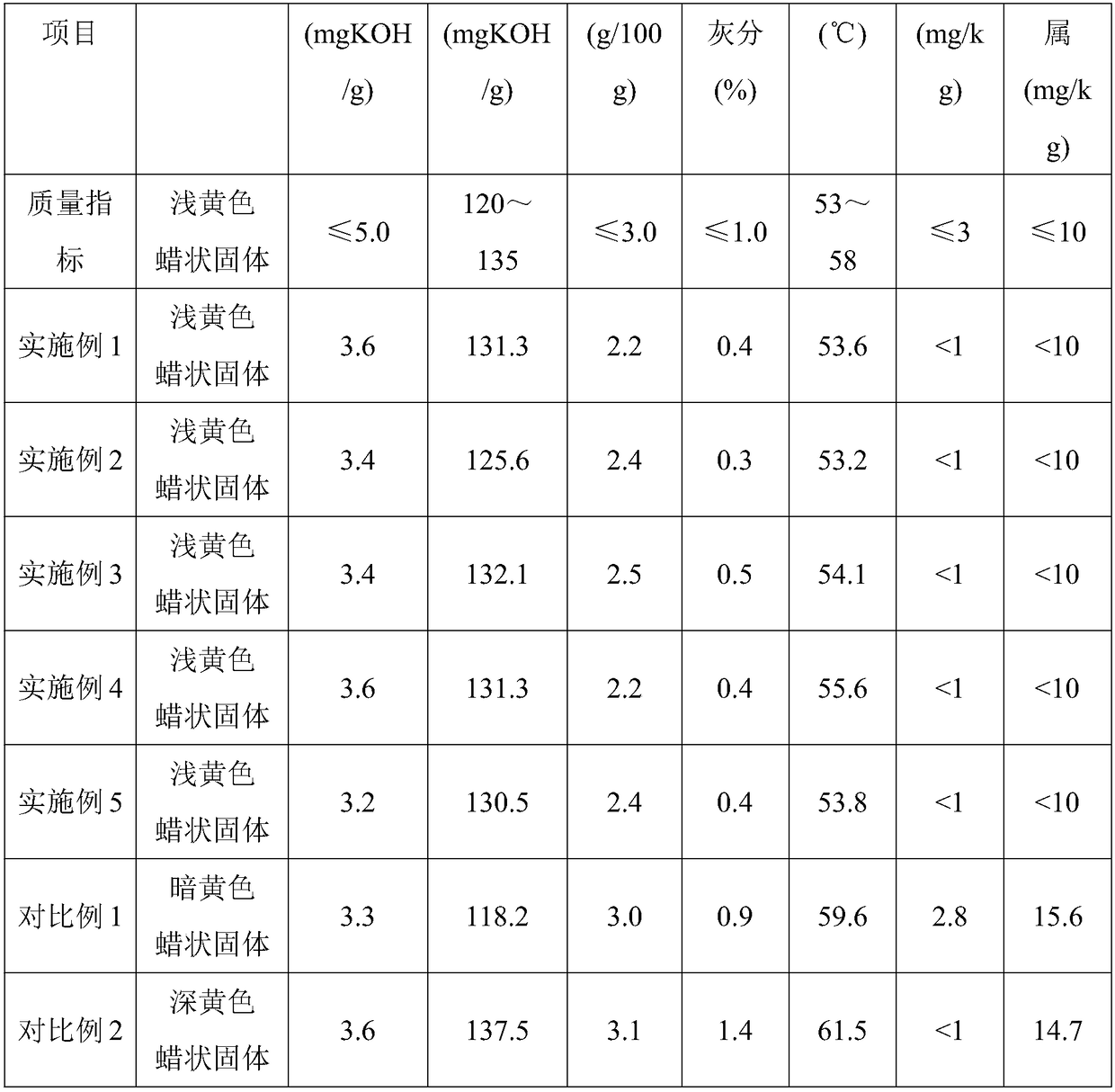

Embodiment 1

[0022] Embodiment 1 A kind of production method of polyglycerol fatty acid ester

[0023] Raw materials: glycerin 900kg, stearic acid 1000kg, catalyst 12.5kg. The catalyst described therein is a compound of sodium hydroxide and calcium hydroxide, and its molar ratio is 1:0.5.

[0024] The preparation method of described polyglycerol ester comprises the steps:

[0025] 1. Pump accurately weighed glycerin into the reaction kettle, turn on the heating device and stirring device, and control the temperature of the material at about 80°C; slowly add 1 / 3 of the catalyst into the reaction kettle, feed nitrogen, and turn on the water circulation pump (vacuum degree Control at 0.01MPa), gradually increase the temperature; raise the temperature of the material to 220-240°C, control the vacuum at 0.07Mpa, keep stirring for 150 minutes; stop heating, open the cooling water valve, adjust the vacuum to 0.03Mpa, under the protection of nitrogen , When the temperature of the materia...

Embodiment 2

[0028] Embodiment 2 A kind of production method of polyglycerol fatty acid ester

[0029] Raw materials: glycerin 1200kg, stearic acid 1200kg, catalyst 14.5kg. The catalyst described therein is a compound of sodium hydroxide and calcium hydroxide, and its molar ratio is 1:0.7.

[0030] The preparation method of described polyglycerol ester comprises the steps:

[0031] 1. Pump accurately weighed glycerin into the reaction kettle, turn on the heating device and stirring device, and control the temperature of the material at about 80°C; slowly add 1 / 3 of the catalyst into the reaction kettle and pass in nitrogen, and turn on the water circulation pump ( The vacuum degree is controlled at 0.02MPa), and the temperature is gradually raised; the temperature of the material is raised to 230-250°C, the vacuum degree is controlled at 0.07Mpa, and the temperature is kept and stirred for 180 minutes. Stop heating, open the cooling water valve, adjust the vacuum to 0.03Mpa, unde...

Embodiment 3

[0034] Embodiment 3 A kind of production method of polyglycerol fatty acid ester

[0035] Raw materials: glycerin 1400kg, stearic acid 1300Kg, catalyst 15.0kg. The catalyst described therein is a compound of sodium hydroxide and calcium hydroxide, and its molar ratio is 1:0.9.

[0036] The preparation method of described polyglycerol ester comprises the steps:

[0037] 1. Pump accurately weighed glycerin into the reaction kettle, turn on the heating device and stirring device, and control the temperature of the material at about 80°C; slowly add 1 / 3 of the catalyst into the reaction kettle, feed nitrogen, and turn on the water circulation pump (vacuum temperature is controlled at 0.03MPa), and the temperature is gradually raised; the temperature of the material is raised to 240-260°C, the vacuum degree is controlled at 0.06Mpa, and the temperature is kept and stirred for 240 minutes. Stop heating, open the cooling water valve, adjust the vacuum to 0.03Mpa, under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com