Safe and stable medicine rubber plug material and preparing method thereof

A safe, stable, rubber stopper technology, applied in the field of medical materials, can solve the problems of film hanging and powder hanging, affecting drug efficacy, falling debris, etc., and achieve the effect of good medicinal compatibility, good sealing and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

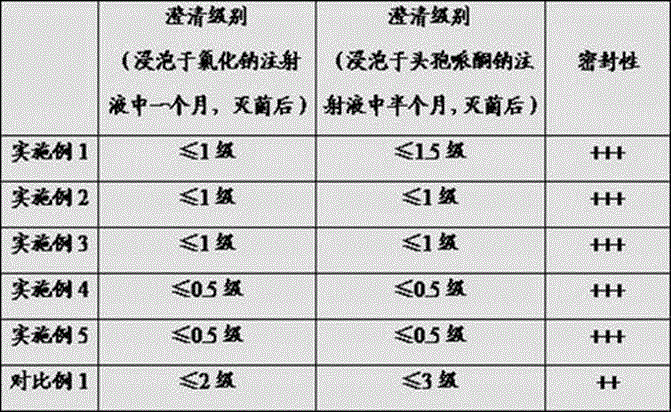

Examples

Embodiment 1

[0020] A method for preparing a safe and stable medical rubber stopper material, comprising the following preparation steps:

[0021] Step 1. Weigh each raw material by mass parts: 42 parts of butyl rubber, 14 parts of silicone rubber, 6 parts of polyether ketone, 4 parts of methyl succinic anhydride, 4 parts of sodium styrene sulfonate, 3 parts of fucose, 4 parts of aspartic acid, 6 parts of 1,5-pentanedithiol, 2 parts of 2-(2-ethoxycarbonylallyloxy) ethylphosphonic acid, 3 parts of tetrabenzylthiuram disulfide, poly 3 parts of methyl hydrogen siloxane, 4 parts of vitamin A palmitate, 5 parts of benzoyl peroxide, 4 parts of nano zinc oxide, 15 parts of glycerin;

[0022] Step 2. Add butyl rubber and aspartic acid to the internal mixer, first banbury at 105°C for 10 minutes; then add silicone rubber, and then banbury at 125°C for 10 minutes to obtain the banbury;

[0023] Step 3, mix the banburying material of step 2 with polyether ketone, methyl succinic anhydride, sodium st...

Embodiment 2

[0026] A method for preparing a safe and stable medical rubber stopper material, comprising the following preparation steps:

[0027] Step 1. Weigh each raw material in parts by mass: 56 parts of butyl rubber, 20 parts of silicone rubber, 11 parts of polyether ketone, 9 parts of methyl succinic anhydride, 8 parts of sodium styrene sulfonate, 7 parts of fucose, 8 parts of aspartic acid, 13 parts of 1,5-pentanedithiol, 6 parts of 2-(2-ethoxycarbonylallyloxy) ethylphosphonic acid, 7 parts of tetrabenzylthiuram disulfide, poly 6 parts of methyl hydrogen siloxane, 8 parts of vitamin A palmitate, 9 parts of benzoyl peroxide, 8 parts of nano zinc oxide, 23 parts of glycerin;

[0028] Step 2. Add butyl rubber and aspartic acid to the internal mixer, first banbury at 128°C for 20 minutes; then add silicone rubber, and then banbury at 140°C for 30 minutes to obtain the banbury;

[0029] Step 3, mix the banburying material of step 2 with polyether ketone, methyl succinic anhydride, sodi...

Embodiment 3

[0032] A method for preparing a safe and stable medical rubber stopper material, comprising the following preparation steps:

[0033] Step 1. Weigh each raw material according to parts by mass: 49 parts of butyl rubber, 17 parts of silicone rubber, 8 parts of polyether ketone, 6 parts of methyl succinic anhydride, 6 parts of sodium styrene sulfonate, 5 parts of fucose, 6 parts of aspartic acid, 10 parts of 1,5-pentanedithiol, 4 parts of 2-(2-ethoxycarbonylallyloxy) ethylphosphonic acid, 5 parts of tetrabenzylthiuram disulfide, poly 4 parts of methyl hydrogen siloxane, 6 parts of vitamin A palmitate, 7 parts of benzoyl peroxide, 6 parts of nano zinc oxide, 19 parts of glycerin;

[0034] Step 2. Add butyl rubber and aspartic acid to the internal mixer, first banbury at 116°C for 15 minutes; then add silicone rubber, and then banbury at 132°C for 20 minutes to obtain the banbury;

[0035] Step 3, mix the banburying material of step 2 with polyether ketone, methyl succinic anhydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com