Construction method for surface coat of wooden article

A construction method and technology for wood products, which can be applied to the device for coating liquid on the surface, pretreatment surface, coating and other directions, which can solve the problem that hardness, wear resistance, high temperature resistance, acid and alkali resistance cannot meet the performance requirements of traditional paints and other problems, to achieve the effect of improving anti-ultraviolet aging performance, good stability and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

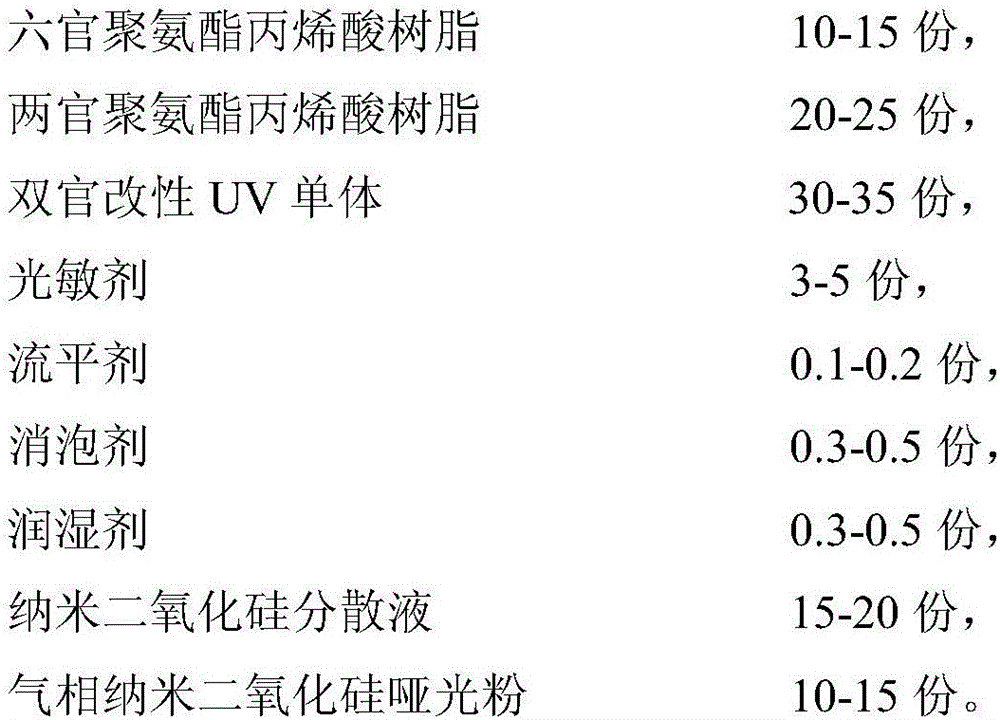

[0052] A kind of UV wooden original paint, comprises the component of following parts by weight:

[0053]

[0054]Preparation method of UV Kihara paint: (1) Put 15 parts of hexafunctional urethane acrylic resin, 25 parts of difunctional urethane acrylic resin, 30 parts of bifunctional modified UV monomer, 4 parts of photosensitizer, 0.2 1 part of leveling agent, 0.3 part of defoamer, 0.5 part of wetting agent, under the mixer speed of 2000RPM, stir for 20 minutes, make the mix evenly, and obtain clear and transparent component A; (2) under the mixer speed of 400RPM, Stir component A, and add 15 parts of nano-silica dispersion liquid at the same time, stir for 10 minutes, mix evenly, and obtain component B; (3) adjust the speed of the mixer to 800PRM, stir component B, and add 10 parts of Gas-phase nano-silica matt powder, stirred for 20 minutes, and mixed uniformly, the UV Kihara paint of the present invention was obtained.

[0055] A construction method for wood product s...

Embodiment 2

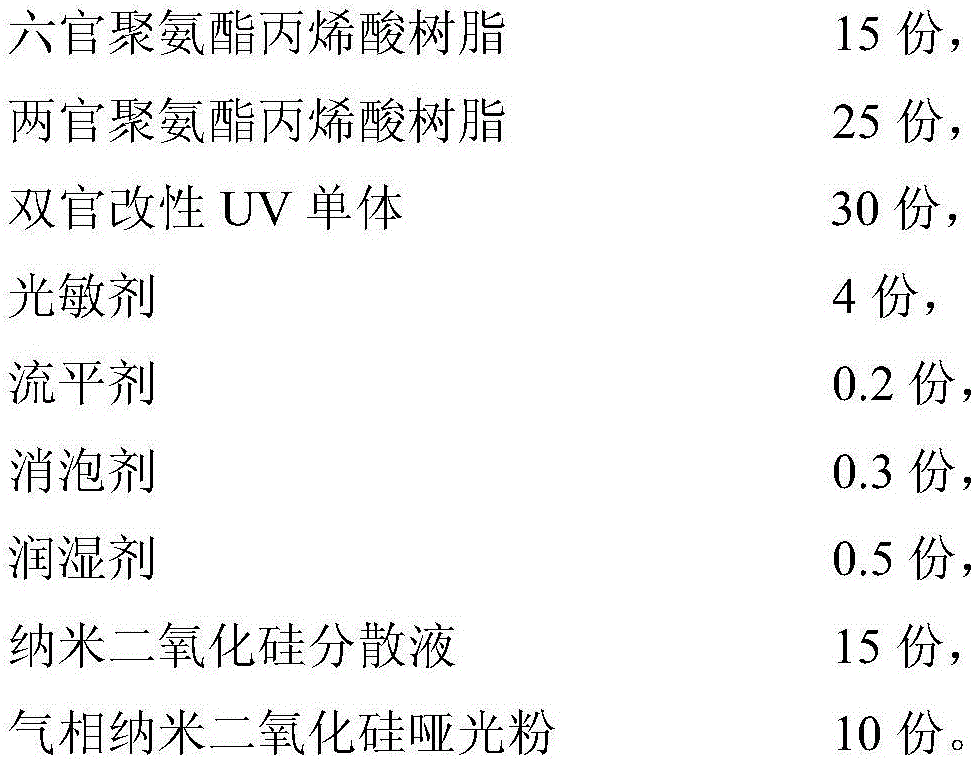

[0064] A kind of UV wooden original paint, comprises the component of following parts by weight:

[0065]

[0066] Raw materials adopt the above proportions by weight, and the method of Example 1 is used to prepare UV wood original paint.

[0067] A construction method for wood product surface paint, comprising the steps of:

[0068] (1) Surface sanding treatment to ensure that the surface of the plain board is smooth and burr-free;

[0069] (2) Primer treatment and UV drying: Coat the treated plain board with UV wood original paint, and ensure that the coating amount is 6g / m 2 , and then dried with a UV dryer, the drying energy is 110mJ / cm 2 ;

[0070] (3) Coloring and drying: the dried plain board is coated with water-based wood lacquer, and the coating amount is guaranteed to be 12g / m 2 , let the water-based original wood paint enter the fiber tube hole, and then place the plain board in a 10-20-meter-long infrared leveling channel to dry, and the drying condition is...

Embodiment 3

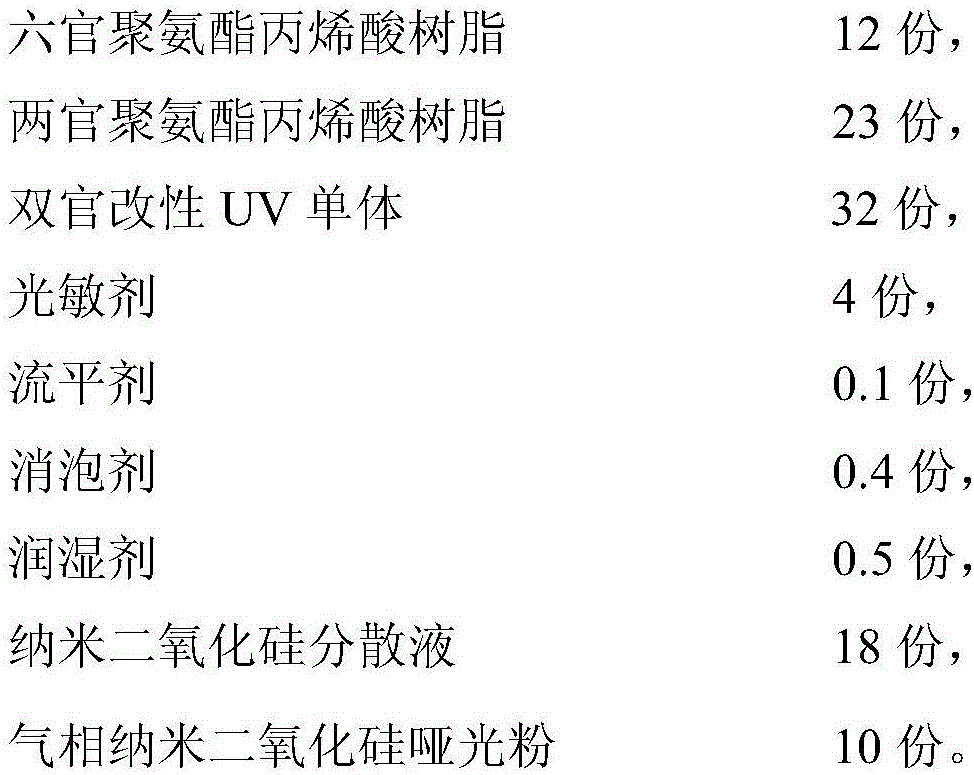

[0076] A kind of UV wooden original paint, comprises the component of following parts by weight:

[0077]

[0078]

[0079] Raw materials adopt the above proportions by weight, and the method of Example 1 is used to prepare UV wood original paint.

[0080] A construction method for wood product surface paint, comprising the steps of:

[0081] (1) Surface sanding treatment to ensure that the surface of the plain board is smooth and burr-free;

[0082] (2) Primer treatment and UV drying: Coat the treated plain board with UV wood original paint, and ensure that the coating amount is 5g / m 2 , and then dried with a UV dryer, the drying energy is 100mJ / cm 2 ;

[0083] (3) Coloring and drying: the dried plain board is coated with water-based wood lacquer, and the coating amount is guaranteed to be 10g / m 2 , let the water-based original wood paint enter the fiber tube hole, and then place the plain board in a 10-20-meter-long infrared leveling channel to dry, and the drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com