45 steel transmission shaft quick ion nitriding method

A technology of ion nitriding and transmission shaft, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., to achieve the effect of accelerating ion nitriding speed, overcoming low nitriding efficiency and increasing surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

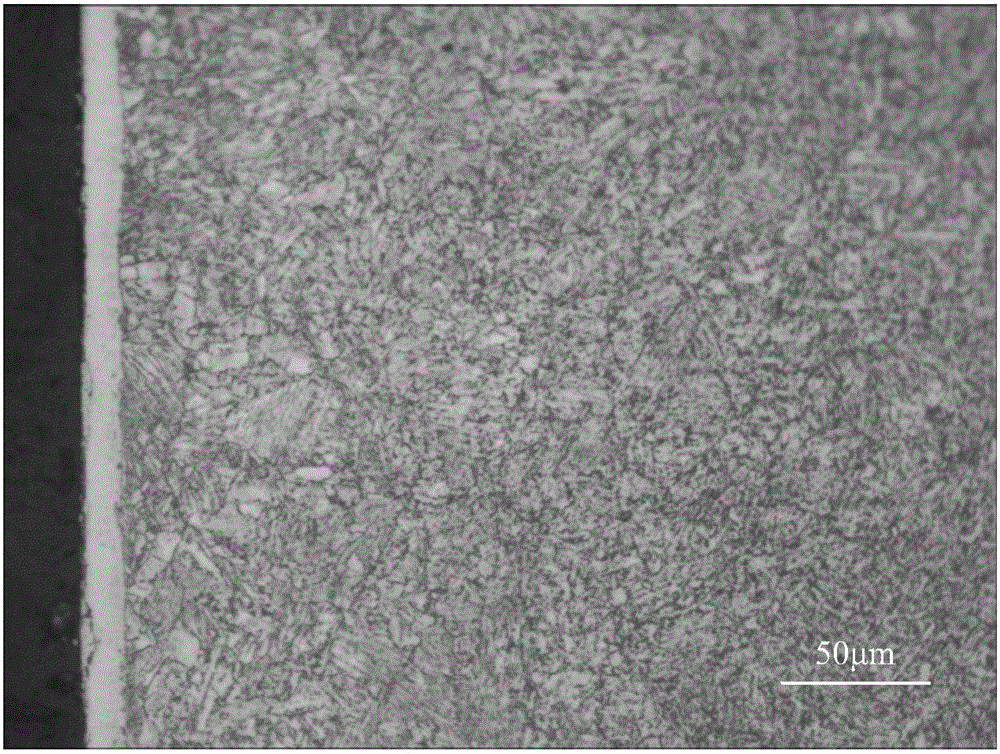

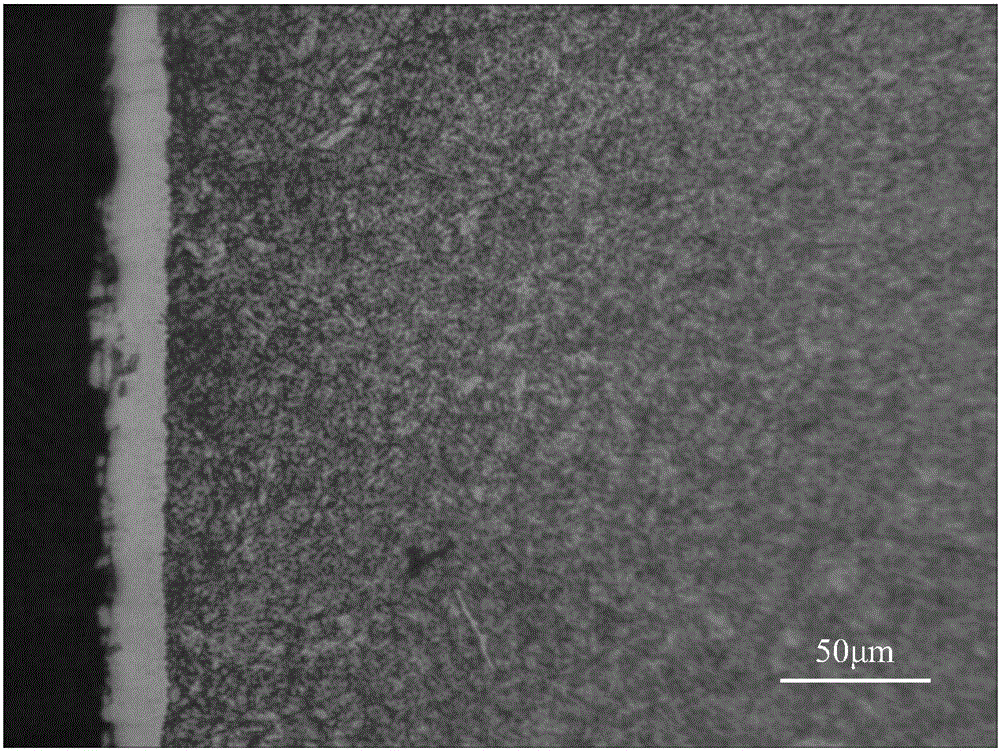

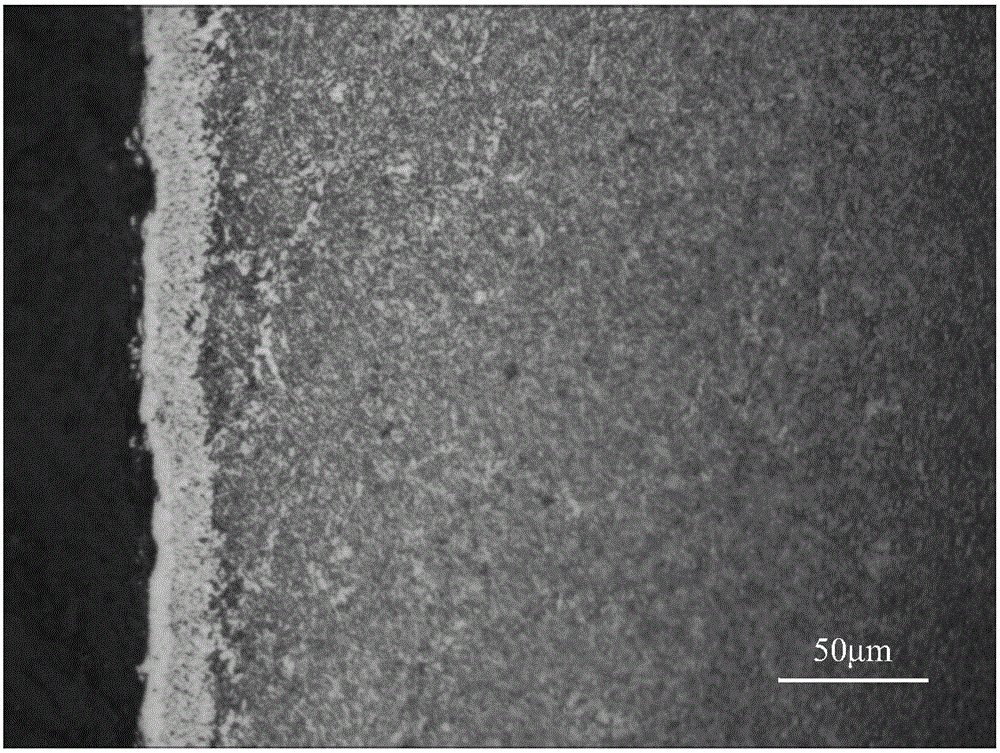

Image

Examples

Embodiment

[0056] 1) Take a sample from the 45 steel drive shaft, process and cut it into a sample, and the sample size is 10mm×10mm×5mm;

[0057] 2) Soak the sample in 50 mL of absolute ethanol for 12 hours to remove the oil on the surface of the sample;

[0058] 3) The sample is subjected to quenching and tempering treatment, first heating up to 840°C for 12 minutes, water cooling to room temperature, then heating up to 580°C for 30 minutes, water cooling to room temperature;

[0059] 4) Grind the samples to the mirror surface with 500#~2000# SiC sandpaper respectively;

[0060] 5) Soak the sample in 20mL of absolute ethanol and perform ultrasonic cleaning for 15 minutes to remove oxides and stains on the surface of the sample, blow dry with a hair dryer, and set aside;

[0061] 6) The sample is subjected to sandblasting treatment, using 46 mesh brown corundum sand for sandblasting. During sandblasting, the distance between the sample and the nozzle is 5cm, the angle is 45°, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com