Film forming solution of aluminum material surface collaborative optimization type chromium-free yellow conversion film and method for preparing conversion film

A technology of collaborative optimization and conversion coating, applied in the direction of metal material coating process, etc., can solve the problems of difficult promotion of chromium-free chemical conversion treatment technology, inability to discover product quality problems in time, and difficulty in real-time online judgment, etc., and achieve a wide processing time range. , Excellent protective performance, stable effect of film-forming solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

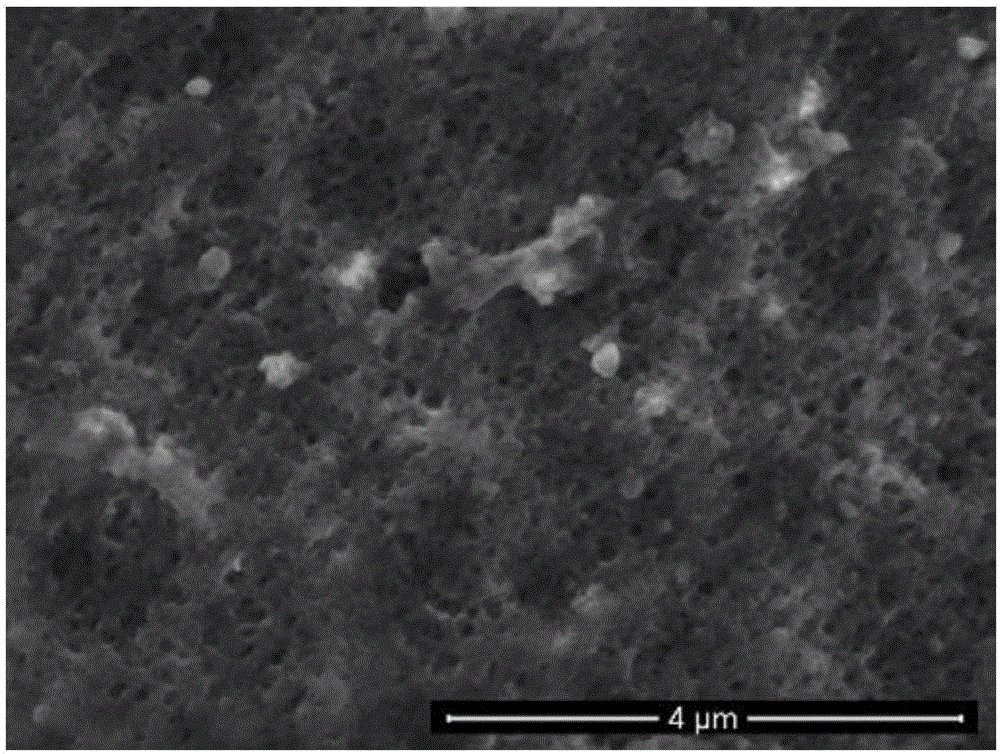

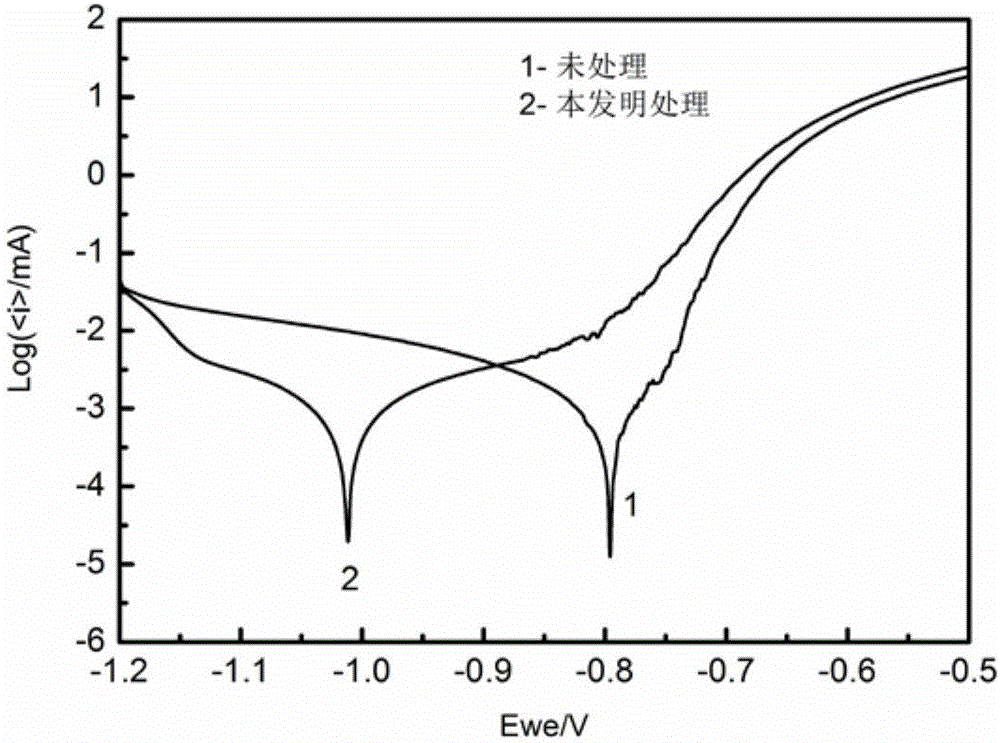

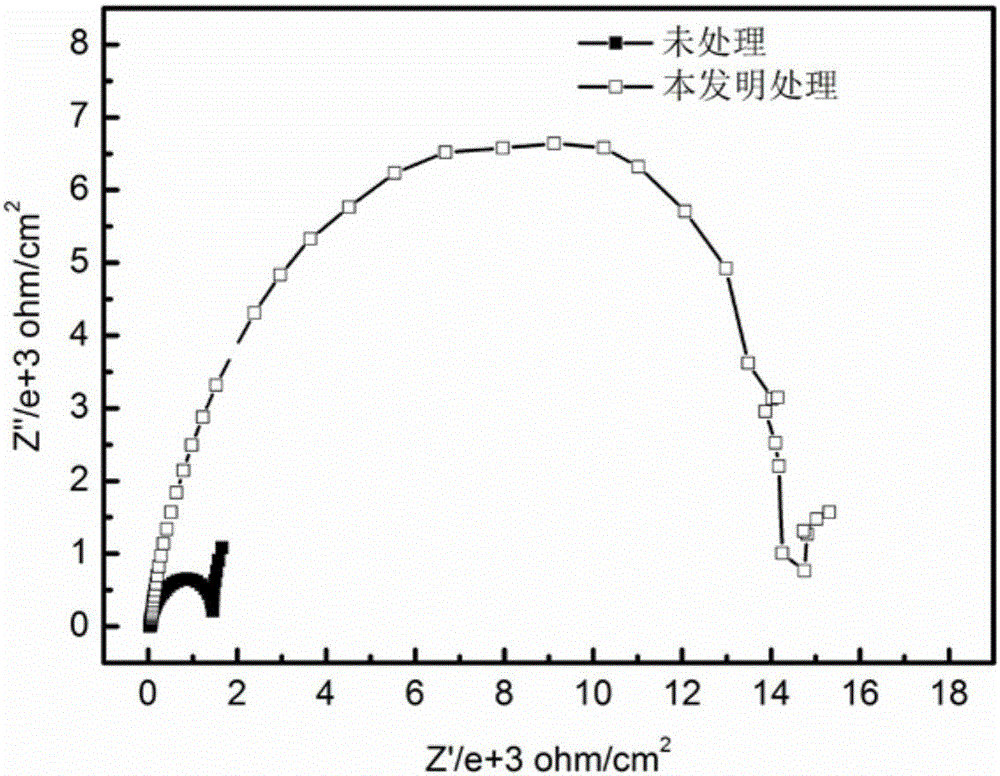

Image

Examples

Embodiment 1

[0047] An embodiment of the film-forming solution of the synergistically optimized chromium-free yellow conversion film on the surface of aluminum-based materials described in the present invention, the film-forming solution contains components at the following concentrations:

[0048] Potassium molybdate 25ppm, fluotitanic acid 25ppm, tannic acid 50ppm, hydrofluoric acid 50ppm, disodium edetate 10ppm, sodium borate 20ppm, fatty alcohol polyoxyethylene ethers 5ppm.

[0049] Stir and dissolve each component in water, adjust the pH value of the solution to 3.0, add tap water until the volume of the film-forming solution is 1000 mL, and obtain the film-forming solution described in this example.

[0050] The method for preparing a chromium-free yellow conversion coating on the surface of aluminum-based materials by using the film-forming solution described in this embodiment includes the following steps:

[0051] (1) Pretreatment: ① Take a 50mm×100mm sample of aluminum-based mate...

Embodiment 2

[0057] An embodiment of the film-forming solution of the synergistically optimized chromium-free yellow conversion film on the surface of aluminum-based materials described in the present invention, the film-forming solution contains components at the following concentrations:

[0058] Sodium molybdate 50ppm, tannic acid 50ppm, hydrofluoric acid 60ppm, disodium edetate 20ppm, sodium silicate 40ppm, fatty alcohol polyoxyethylene ether 5ppm.

[0059] Stir and dissolve each component in water, adjust the pH value of the solution to 3.5, and add tap water until the volume of the film-forming solution is 1000 mL.

[0060] The method for preparing a chromium-free yellow conversion coating on the surface of aluminum-based materials by using the film-forming solution described in this embodiment includes the following steps:

[0061] (1) Pretreatment: ① Take a 50mm×100mm sample of aluminum-based material and punch a hole, and connect the aluminum wire at the hole; The erosion amount ...

Embodiment 3

[0066] An embodiment of the film-forming solution of the synergistically optimized chromium-free yellow conversion film on the surface of aluminum-based materials described in the present invention, the film-forming solution contains components at the following concentrations:

[0067] Sodium vanadate 25ppm, fluotitanic acid 75ppm, tannic acid 100ppm, hydrofluoric acid 100ppm, disodium edetate 50ppm, sodium borate 40ppm, sodium dodecylbenzenesulfonate 5ppm.

[0068] Stir and dissolve each component in water, adjust the pH value of the solution to 3.5, and add tap water until the volume of the film-forming solution is 1000 mL.

[0069] The method for preparing a chromium-free yellow conversion coating on the surface of aluminum-based materials by using the film-forming solution described in this embodiment includes the following steps:

[0070] (1) Pretreatment: ① Take a 50mm×100mm sample of aluminum-based material and punch a hole, and connect the aluminum wire at the hole; ② ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com