Pre-drying brown coal power generation system integrated with air heater and pre-drying brown coal power generation method

A technology of power generation system and air heater, which is applied in the direction of combustion method, dry solid material, dry gas arrangement, etc. It can solve the problems of power generation system efficiency decline, boiler exhaust temperature rise, steam turbine output reduction, etc., and achieve power regulation process The effect of continuous, efficient operation and shortened payback period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

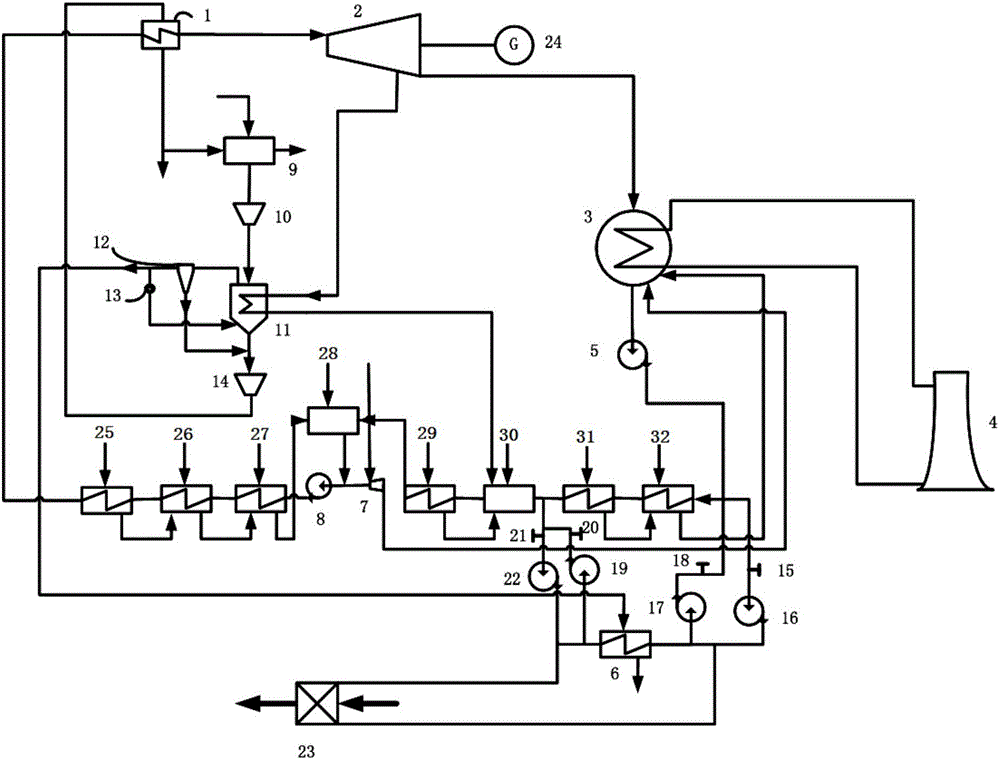

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings

[0027] like figure 1 As shown, the present invention is a pre-dried lignite power generation system with integrated air heater, including a boiler 1, a steam turbine 2, a generator 24, a condenser 3, a cooling tower 4, a condensate pump 5, a heat recovery system, a drying system and a heating system. The blower system, according to the water flow direction, the heat recovery system includes the first to third high pressure heaters 25-27, the deaerator 26 and the first to fourth low pressure heaters 29-32 connected in sequence, and the drying system includes raw coal preheating 9, coal crusher 10, fluidized bed dryer 11 with built-in heater, dust collector 12, fan 13, coal pulverizer 14, and the heater system includes a drying exhaust waste heat recovery device 6, a first valve 15, a first A pump 16 , a second pump 17 , a second valve 18 , a third pump 19 , a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com