High brightness AlGaInP light emitting diode with copper substrate and manufacture method thereof

A technology for light-emitting diodes and a manufacturing method, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of reduced light-emitting diode light-emitting efficiency, low current injection efficiency, limited expansion capability, etc., and achieves excellent heat dissipation function, low cost, and increased The effect of light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

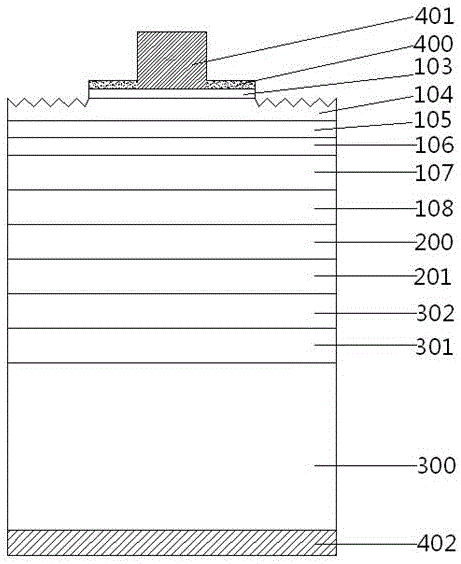

[0028] One, concrete implementation steps of the present invention:

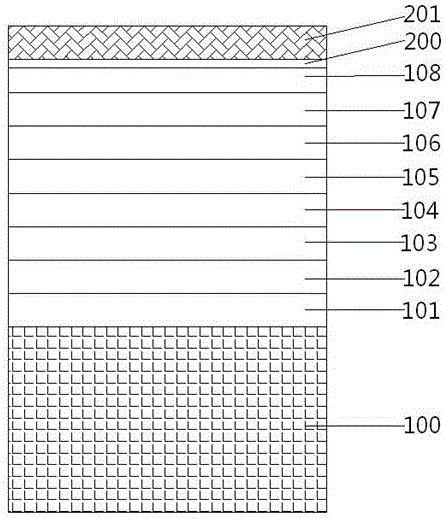

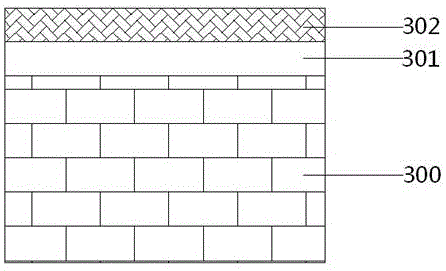

[0029] 1. On the GaAs temporary substrate 100 as the epitaxial layer, the n-GaAs buffer layer 101, the GaInP barrier layer 102, the n-GaAs ohmic contact layer 103, and the roughened n- AlGaInP layer 104, n-AlGaInP confinement layer 105, MQW active layer 106, p-AlGaInP confinement layer 107, p-GaP current spreading layer 108.

[0030] Wherein the GaAs temporary substrate 100 has a thickness of 250-350 μm.

[0031] The n-GaAs ohmic contact layer 103 has a thickness of 30-500nm, preferably 45nm, and a silicon doping concentration of 1×10 18 cm -3 ~3×10 18 cm -3 (in this example, preferably 1×10 18 cm -3 above).

[0032] The thickness of the roughenable n-AlGaInP layer 104 is 0.5-3 μm.

[0033] The thickness of the P-GaP current spreading layer 108 is 2-5 μm, and the magnesium doping concentration is 8×10 17 cm -3 ~1×10 19 cm -3 .

[0034] Clean the p-GaP current spreading layer 108 with 511 soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com