Use of sulfur compounds and selenium compounds as precursors for nanostructured materials

A technology of sulfur compounds and selenium compounds, applied in the direction of binary selenium/tellurium compounds, metal selenide/telluride, lead sulfide, etc., can solve problems such as poor conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0110] Scheme 3. Preparation of Selenium Precursor Compounds

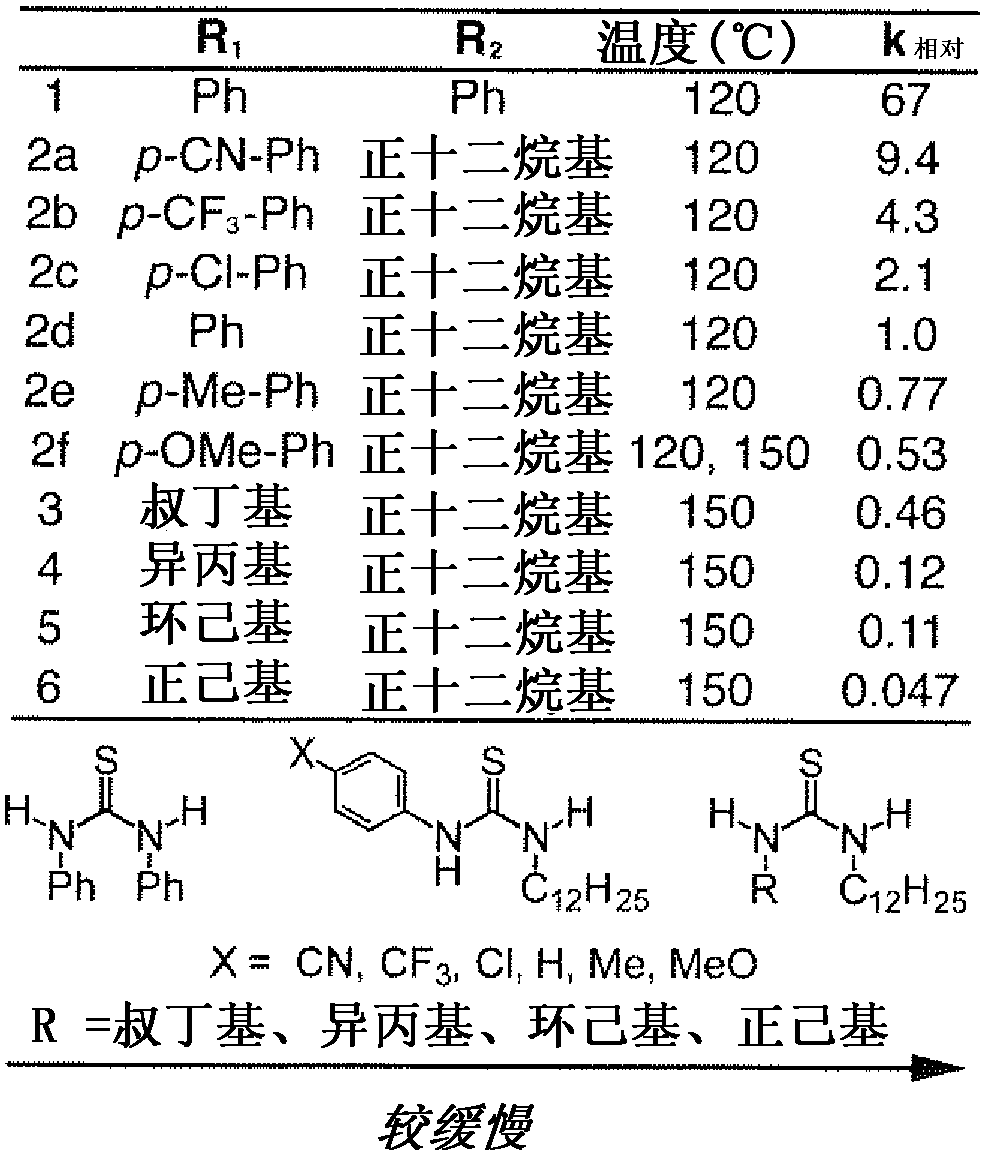

[0111] As a non-limiting example, in compounds of Scheme 3, R 1 Can be substituted or unsubstituted alkyl, substituted or unsubstituted cycloalkyl, substituted or unsubstituted alkenyl, substituted or unsubstituted cycloalkenyl, or substituted or unsubstituted Substituted aryl; R 2 and R 3 can be independently H, substituted or unsubstituted alkyl, substituted or unsubstituted cycloalkyl, substituted or unsubstituted alkenyl, substituted or unsubstituted cycloalkenyl, or substituted or unsubstituted aryl; and X can be N, O, S, Se or P, with the proviso that when X is O, S or Se, R 2 does not exist. In certain embodiments, X can be N, and selenourea can be prepared. In some embodiments, R 1 Can be an unsubstituted alkyl or unsubstituted cycloalkyl group, eg, n-butyl, isopropyl, cyclohexyl or tert-butyl. In some embodiments, R 2 and R 3 can independently be H, unsubstituted alkyl, or unsubstituted alkenyl (e...

Embodiment 1

[0147] Example 1: Precursor Synthesis

[0148] Embodiment 1 (a): zinc oleate (Zn(oleate) 2 )Synthesis

[0149] Dissolve 9.54 mmol (0.382 g) of sodium hydroxide in 90 mL of methanol. 9.54 mmol (2.694 g) of oleic acid were added and the solution was stirred for five minutes. A solution of 3.18 mmol (0.947 g) of zinc nitrate hexahydrate was prepared in 15 mL of methanol and added dropwise, forming a white precipitate. After the addition, the white solid was collected by vacuum filtration, washed with excess methanol, and dried under vacuum for two days before being stored in a glove box.

[0150] Embodiment 1 (b): lead oleate (Pb (oleate) 2 )Synthesis

[0151] Using conventional methods, dissolve 90 mmol sodium hydroxide in 2 L methanol. Once dissolved, 90 mmol oleic acid was added and stirred for about 5 minutes. Then add 40mmol of Pb(NO 3 ) 3 With another 500 mL of methanol, and heat the whole solution until everything is dissolved. Once a clear solution was obtaine...

Embodiment 2

[0177] Example 2: Nanocrystal Synthesis

[0178] Embodiment 2 (a): the synthesis of copper sulfide nanocrystal

[0179] Copper acetylacetonate (.2616 g, 1 mmol), 1-octadecene (7.89 g, 10 mL), oleamide (1.605 g, 6 mmol), and oleic acid (.2825 g, 1 mmol) were combined in a vial and degassed for 30 minute. The mixture was heated to 160 °C, turned dark blue, and a solution of phenyl-hexylthiourea (.1182 g, .5 mmol) in diphenyl ether (ca. 2 mL) was injected. After 15 minutes, the now dark brown sample was removed from the heat and allowed to cool to room temperature. Nanocrystals were washed by precipitation in methyl acetate, centrifuged at 7000 rpm for 10 minutes, and redispersed in hexane. This process was repeated two more times to thoroughly clean the nanocrystals.

[0180] Example 2(b): Large-Scale Synthesis of PbS Nanocrystals

[0181] 53 mmol (40.815 g) of lead oleate and 220 mL of 1-octadecene were charged into a 500 mL three-neck round bottom flask. After degassin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com