Custard cream with modified starch, and preparation method thereof

A starch and modification technology, which is applied in the field of custard sauce and its preparation with modified starch, can solve the problems of hard taste, lower binding force, poor water retention, etc., achieve mild smell and improve texture performance , Improve the effect of water retention capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

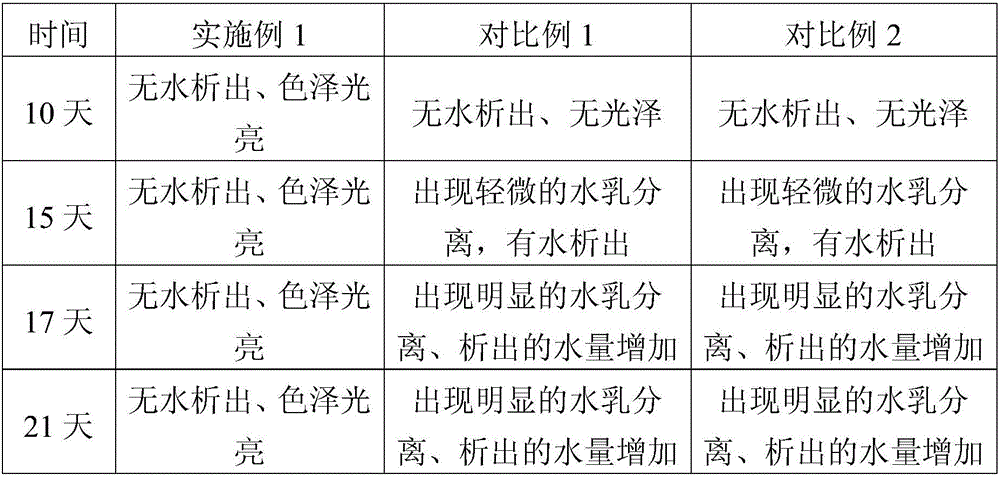

Examples

Embodiment 1

[0028] The custard sauce added with modified starch in this example is prepared from the following raw materials in parts by weight: 43 parts of water, 16 parts of white sugar, 10 parts of fresh egg yolk, 7 parts of whole milk powder, 10 parts of fructose syrup, 8 parts of butter, 6 parts of hydroxypropyl distarch phosphate, 0.15 parts of sucrose fatty acid lipid, 0.1 part of citric acid, and 0.1 part of potassium sorbate.

[0029] The preparation method of the custard sauce added with modified starch in this embodiment, the specific operation steps are:

[0030] 1) Mix white sugar and fresh egg yolk in an egg beater until fluffy and fine, and obtain material 1;

[0031] 2) Mix whole milk powder, fructose syrup, hydroxypropyl distarch phosphate, sucrose fatty acid ester, and water evenly, add to the material 1 prepared in step 1), heat to 92°C in a jacketed pot, heat and stir for 25 minutes, Stir until there are no solid particles to obtain material 2;

[0032] 3) Cool the m...

Embodiment 2

[0034] The custard sauce added with modified starch in this example is prepared from the following raw materials in parts by weight: 36 parts of water, 15 parts of white sugar, 11 parts of fresh egg yolk, 6 parts of whole milk powder, 8 parts of fructose syrup, 6 parts of butter, 5 parts of hydroxypropyl distarch phosphate, 0.1 part of monoglyceride, 0.15 part of citric acid, 0.15 part of sodium dehydroacetate.

[0035] The preparation method of the custard sauce added with modified starch in this embodiment, the specific operation steps are:

[0036] 1) Mix white sugar and fresh egg yolk in an egg beater until fluffy and fine, and obtain material 1;

[0037] 2) Mix whole milk powder, fructose syrup, hydroxypropyl distarch phosphate, sucrose fatty acid ester, and water evenly, add to the material 1 prepared in step 1), heat to 90°C in a sandwich pot, heat and stir for 30 minutes, Stir until there are no solid particles to obtain material 2;

[0038] 3) Cool the material 2 pr...

Embodiment 3

[0040] The custard sauce added with modified starch in this example is prepared from the following raw materials in parts by weight: 50 parts of water, 18 parts of white sugar, 12 parts of fresh egg yolk, 8 parts of whole milk powder, 9 parts of fructose syrup, 7 parts of butter, 8 parts of hydroxypropyl distarch phosphate, 0.2 part of sucrose fatty acid lipid, 0.2 part of citric acid, and 0.2 part of benzoic acid.

[0041] The preparation method of the custard sauce added with modified starch in this embodiment, the specific operation steps are:

[0042] 1) Mix white sugar and fresh egg yolk in an egg beater until fluffy and fine, and obtain material 1;

[0043] 2) Mix whole milk powder, fructose syrup, hydroxypropyl distarch phosphate, sucrose fatty acid ester, and water evenly, add to the material 1 prepared in step 1), heat and stir in a sandwich pot to 95°C for 20 minutes, Stir until there are no solid particles to obtain material 2;

[0044] 3) Cool the material 2 prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com