Modified biocarbon composite material and preparation and application thereof

A composite material, biochar technology, applied in water pollutants, other chemical processes, chemical instruments and methods, etc., can solve the problems of single type of biochar surface groups, uneven structure, restricted development, etc., and achieve industrial application The effect of high prospect, stable physical and chemical properties, and low comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

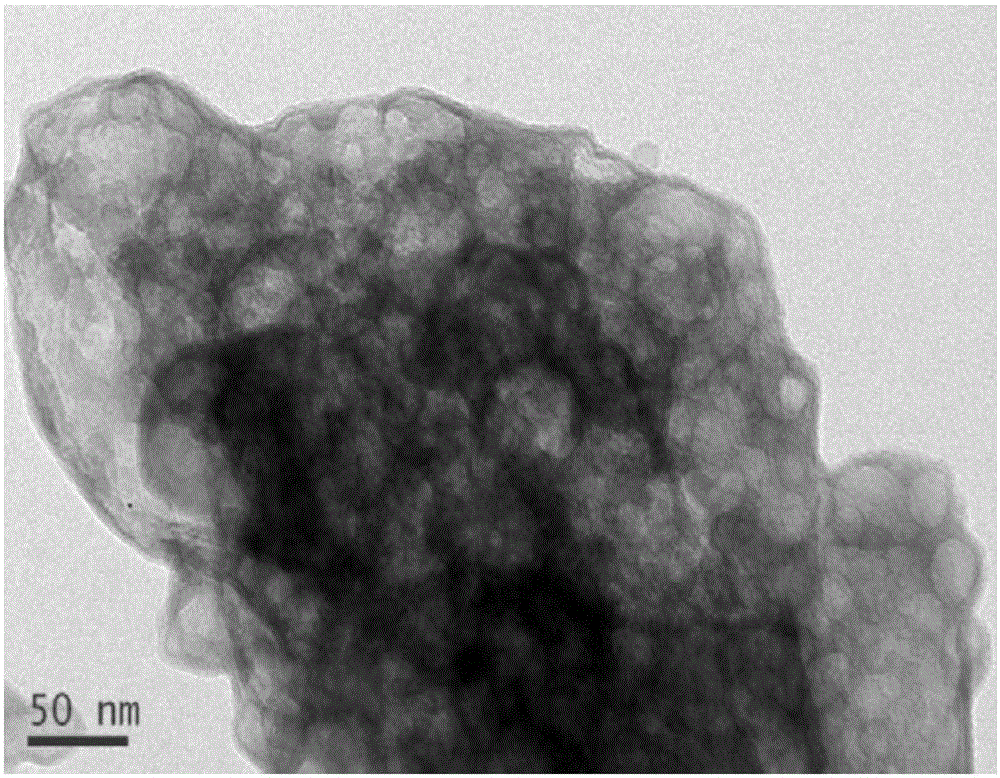

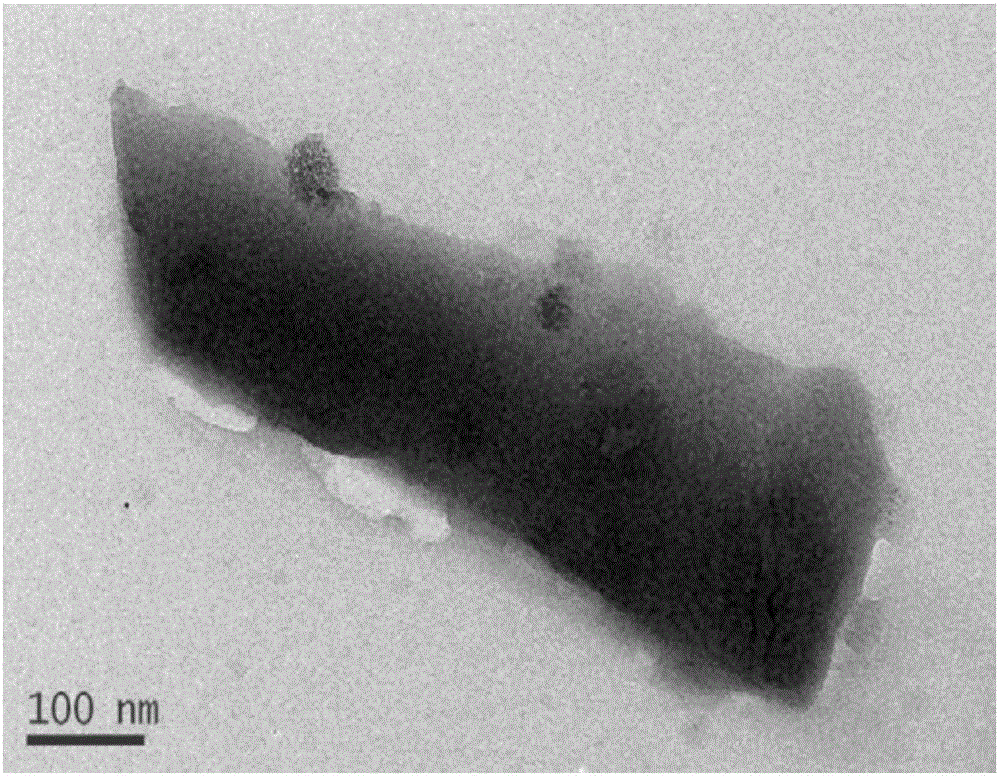

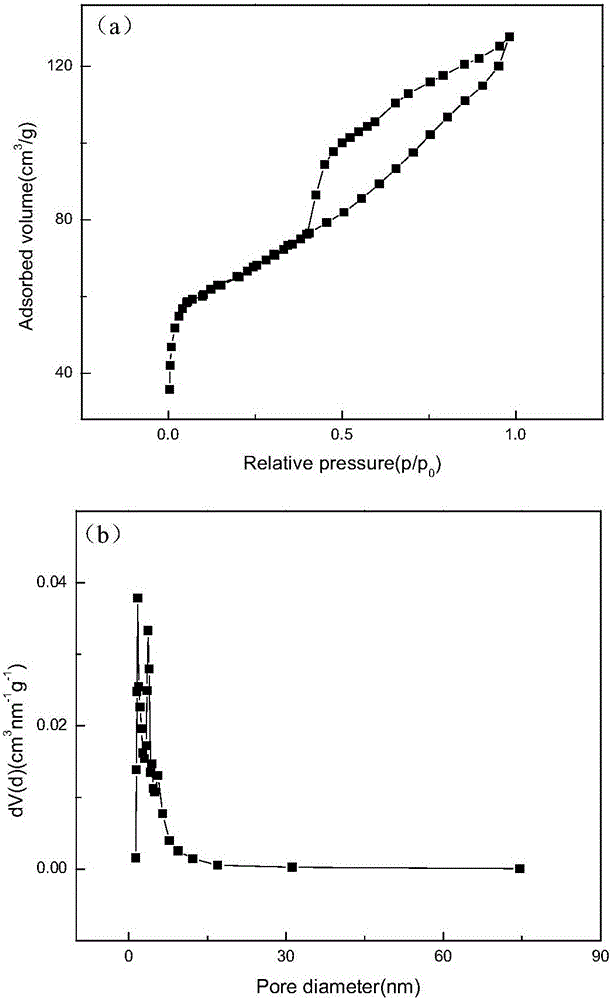

[0021] Adjust the pH of 500mL of 0.01mol / L aluminum sulfate solution to 5.5 with sodium hydroxide solution, boil and stir for 10min. Grind the sawdust with a vibrating mill, take 5g of the sawdust obtained through a 140-mesh sieve, add it to the boiled aluminum sulfate solution, stir it magnetically for 30 minutes, then stir it at room temperature for 5 hours, filter it with suction, and put it in a constant temperature drying oven at 60°C After drying for 12 hours, carbonize the dried samples. The final temperature of carbonization is 300°C, the heating rate is 5°C / min, and nitrogen is protected. Cool naturally to room temperature to obtain the modified biochar composite material.

Embodiment 2

[0023] Adjust the pH of 500mL of 0.02mol / L aluminum sulfate solution to 6.0 with sodium hydroxide solution, boil and stir for 10min. Grind the sawdust with a vibrating mill, take 5g of the sawdust obtained through a 140-mesh sieve, add it to the boiled aluminum sulfate solution, stir it magnetically for 30 minutes, then stir it at room temperature for 5 hours, filter it with suction, and put it in a constant temperature drying oven at 60°C After drying for 12 hours, carbonize the dried sample. The final temperature of carbonization is 400°C, the heating rate is 5°C / min, and nitrogen is protected. Cool naturally to room temperature to obtain the modified biochar composite material.

Embodiment 3

[0025] Under room temperature conditions, the lead-containing solution that is 80mg / L, 200mg / L and 500mg / L is carried out adsorption reaction with the material prepared by 0.02g embodiment 1 respectively to 20mL concentration, wherein reaction time is 6 hours, the lead ion concentration in the filtrate Measured by an inductively coupled plasma emission spectrometer, the adsorption amounts of lead ions are 76.3mg / g, 190.9mg / g and 453.5mg / g respectively, and the removal rates all reach more than 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com