Method for improving heavy metal adsorption performance of biochar

A technology for adsorbing heavy metals and biochar, applied in the field of environmental pollution control, can solve the problems of human health and ecological environment hazards, long-term toxicity, etc., and achieve the effects of improving utilization efficiency, improving adsorption effect, and facilitating transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take the stems and leaves of sun-dried water hyacinth and crack them for 210s under the working condition of microwave cracking furnace power of 1100w to obtain the required powdered biochar. Mix 0.2g powdered biochar, 0.15g phenolic resin and 0.1g ammonium bicarbonate evenly, and then add Stir after 20 drops of 75wt% alcohol. After stirring evenly, put the mixture into a molding mold and apply a molding pressure of 0.05MPa to shape it. Then take out the shaped biochar from the mold, and place it in a microwave cracking furnace with power 700w for activation treatment for 150s.

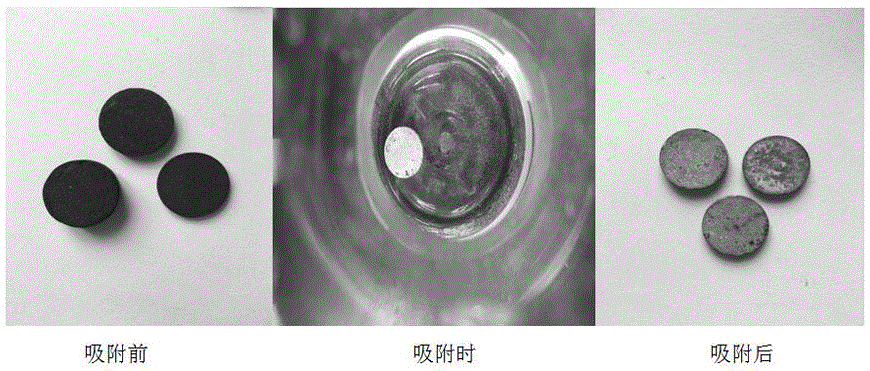

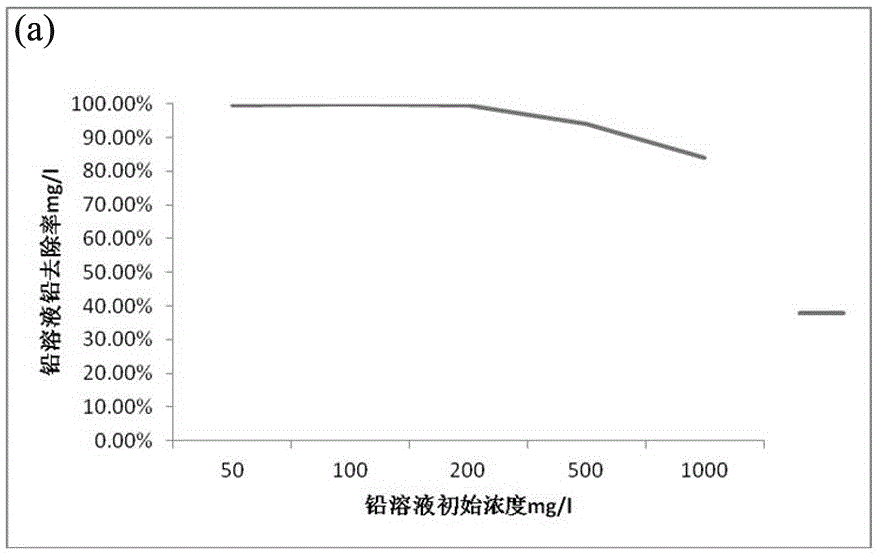

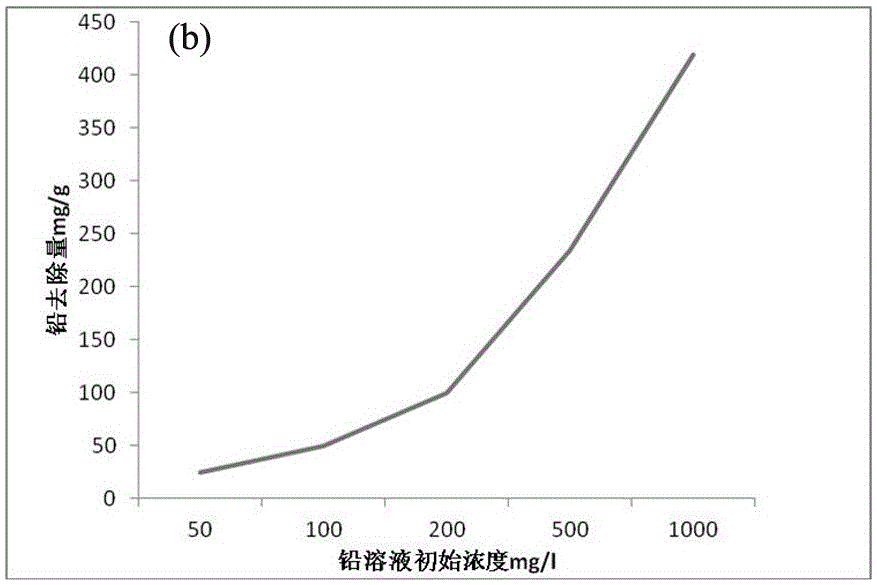

[0025] The prepared shaped activated carbon (such as figure 1 ) is used to adsorb lead ion solution with an initial concentration of 100mg / l, pH=3, place it on a shaking table with a rotation speed of 120r / min for 24h, take the lead solution after adsorption for lead ion concentration test, and the result is that the equilibrium concentration of lead ion solution is 0.02 mg / l, the removal amou...

Embodiment 2

[0027] Take the stems and leaves of sun-dried water hyacinth and crack them for 210s under the working condition of microwave cracking furnace power of 1100w to obtain the required powdered biochar. Mix 0.2g powdered biochar, 0.15g phenolic resin and 0.1g ammonium bicarbonate evenly, and then add Stir after 20 drops of 75wt% alcohol. After stirring evenly, put the mixture into a molding mold and apply a molding pressure of 0.05MPa. Then take out the shaped biochar from the mold and place it in a microwave cracking furnace with a power of 700w. Activation treatment 150s.

[0028] The prepared shaped activated carbon (such as figure 1 ) is used to adsorb lead ion solution with an initial concentration of 200mg / l, pH=3, place it on a shaking table with a rotation speed of 120r / min for 24h, take the lead solution after adsorption for lead ion concentration test, and the result is that the equilibrium concentration of lead ion solution is 0.13 mg / l, the removal amount is 99.935mg / ...

Embodiment 3

[0030] Take the stems and leaves of sun-dried water hyacinth and crack them for 210s under the working condition of microwave cracking furnace power of 1100w to obtain the required powdered biochar. Mix 0.2g powdered biochar, 0.15g phenolic resin and 0.1g ammonium bicarbonate evenly, and then add Stir after 20 drops of 75wt% alcohol. After stirring evenly, put the mixture into a molding mold and apply a molding pressure of 0.05MPa. Then take out the shaped biochar from the mold and place it in a microwave cracking furnace for activation with a power of 700w. Process 150s.

[0031] The prepared shaped activated carbon (such as figure 1 ) is used to adsorb lead ion solution with an initial concentration of 500mg / l, pH=3, placed on a shaking table with a rotation speed of 120r / min for 24 hours, and the lead solution after adsorption is taken for lead ion concentration test, and the result is that the equilibrium concentration of lead ion solution is 30.5 mg / l, the removal amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com