Better-durability concrete

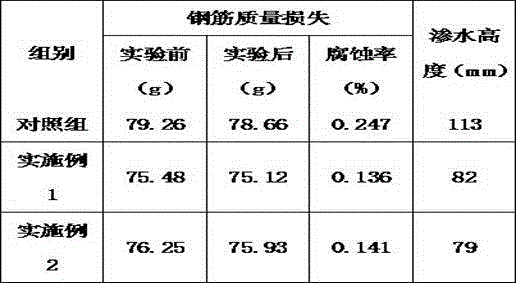

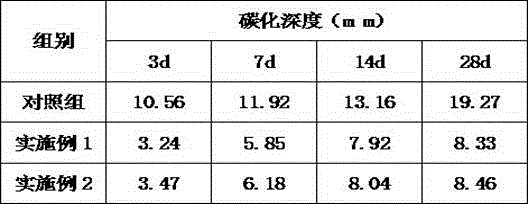

A concrete and durability technology, applied in the field of concrete, can solve the problems of limited natural river sand sources and less durability research, and achieve the effects of reduced maintenance work, excellent carbonation performance, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A kind of concrete with better durability is made of the following raw materials in parts by weight: 27 parts of cement, 15 parts of fly ash, 3 parts of modified ultrafine quartz powder, 15 parts of illite, 6 parts of tire powder, chlorite 3 parts, 14 parts of coal gangue, 4 parts of alkalized rice husk, 2 parts of polycarbonate resin, 0.3 part of tristyrylphenol polyoxyethylene ether, 0.3 part of chlorinated paraffin, 0.4 part of polyisobutylene, 10 parts of water;

[0014] Wherein, the modification method of the ultrafine quartz powder is: take the ultrafine quartz powder and soak it in calcium sulfate with a mass concentration of 12-15% for 40-60 minutes, rinse it with deionized water, and then use a mass concentration of 10-15% Soak in 12% hydrochloric acid solution for 1-1.5 hours, rinse with deionized water until neutral, dry until the moisture is lower than 15%, add polyisobutylene equivalent to 1-2% by weight, 2-3% dioxane Iron and 2-3% chlorinated paraffin, sti...

Embodiment 2

[0019] A kind of concrete with good durability is made of the following raw materials in parts by weight: 30 parts of cement, 12 parts of fly ash, 4 parts of modified ultrafine quartz powder, 14 parts of illite, 4 parts of tire powder, chlorite 4 parts, 16 parts of coal gangue, 5 parts of alkalized rice husk, 2 parts of polycarbonate resin, 0.2 part of tristyrylphenol polyoxyethylene ether, 0.3 part of chlorinated paraffin, 0.5 part of polyisobutylene, 8 parts of water;

[0020] Wherein, the modification method of the ultrafine quartz powder is: take the ultrafine quartz powder and soak it in calcium sulfate with a mass concentration of 12-15% for 40-60 minutes, rinse it with deionized water, and then use a mass concentration of 10-15% Soak in 12% hydrochloric acid solution for 1-1.5 hours, rinse with deionized water until neutral, dry until the moisture is lower than 15%, add polyisobutylene equivalent to 1-2% by weight, 2-3% dioxane Iron and 2-3% chlorinated paraffin, stirre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com