Waterproof scratch-resistant waterborne polyurethane coating and preparation method thereof

A water-based polyurethane and scratch-resistant technology, applied in the field of transfer coatings, can solve the problems of poor water resistance, poor abrasion resistance of water-based coatings, easy moisture absorption, etc., and achieve high storage stability, good solvent resistance, and good compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

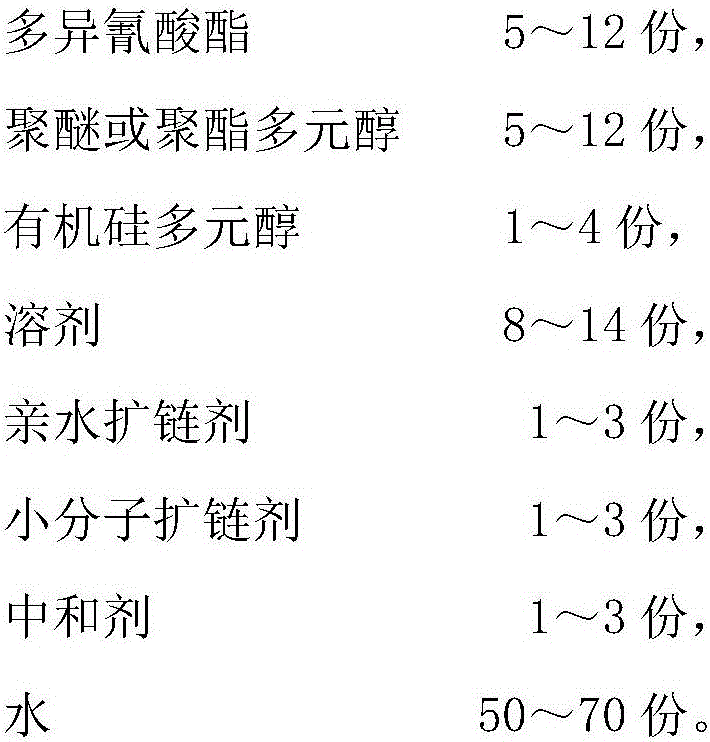

[0032] This embodiment relates to a waterproof and scratch-resistant water-based polyurethane coating, including the following components in parts by weight: 10 parts of polyisocyanate, 10 parts of polyether or polyester polyol, 1 part of silicone polyol, 12 parts of solvent, 3 parts of hydrophilic chain extender, 2 parts of small molecule chain extender, 2 parts of neutralizing agent, 60 parts of water.

[0033] Taking the preparation of 100kg waterproof and scratch-resistant waterborne polyurethane coating as an example, the preparation method of the coating in this embodiment specifically includes the following steps:

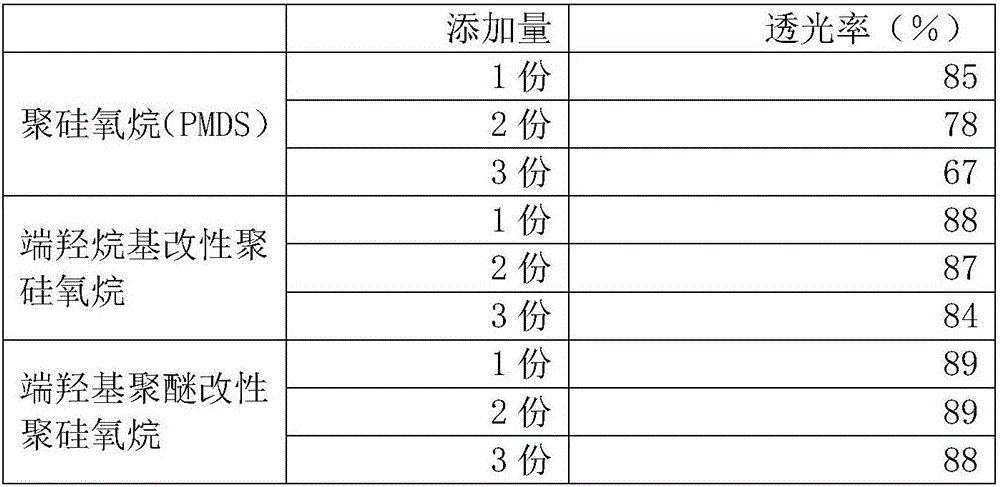

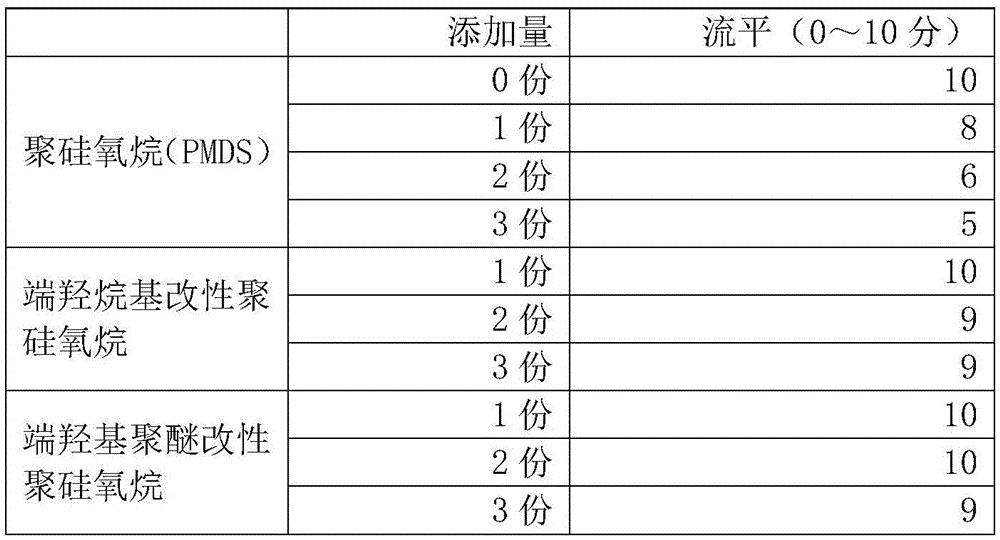

[0034] (1) Mix 10kg of polyester polyol (hydroxyl-terminated polyester polyol with a functionality greater than or equal to 2, with a molecular weight of 2000 to 2500), 1kg of silicone polyol (polysiloxane organosilicon compound modified with hydroxyalkyl groups) ) at 120°C, stirring and dehydrating under vacuum conditions for 0.5 hours, until the water cont...

Embodiment 2

[0049] This embodiment relates to a waterproof and scratch-resistant water-based polyurethane coating, including the following components in parts by weight: 12 parts of polyisocyanate, 10 parts of polyether or polyester polyol, 2 parts of silicone polyol, 10 parts of solvent, 3 parts of hydrophilic chain extender, 3 parts of small molecule chain extender, 2 parts of neutralizer, 58 parts of water.

[0050] Taking the preparation of 100kg waterproof and scratch-resistant waterborne polyurethane coating as an example, the preparation method of the coating in this embodiment specifically includes the following steps:

[0051] (1) 10kg of polyester polyol (hydroxyl-terminated polyester polyol with a functionality greater than 2, molecular weight 3500-4000), 2kg of silicone polyol (hydroxyl-terminated polyether modified polysiloxane organosilicon compound) Stir and dehydrate at 120°C for 0.5 hours under vacuum until the water content in polyester polyol and silicone polyol is less...

Embodiment 3

[0059] This embodiment relates to a waterproof and scratch-resistant water-based polyurethane coating, including the following components in parts by weight: 8 parts of polyisocyanate, 12 parts of polyether or polyester polyol, 3 parts of silicone polyol, 10 parts of solvent, 3 parts of hydrophilic chain extender, 2 parts of small molecule chain extender, 2 parts of neutralizing agent, 60 parts of water.

[0060] Taking the preparation of 100kg waterproof and scratch-resistant waterborne polyurethane coating as an example, the preparation method of the coating in this embodiment specifically includes the following steps:

[0061] (1) 12kg of polyether polyol (hydroxyl-terminated polyoxyalkylene polyol with a functionality of 3, molecular weight of 3000-3500), 3kg of silicone polyol (polysiloxane organosilicon compound modified with hydroxyalkyl group) ) at 120°C, stirring and dehydrating under vacuum conditions for 0.5 hours, until the water content in polyether polyol and sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com