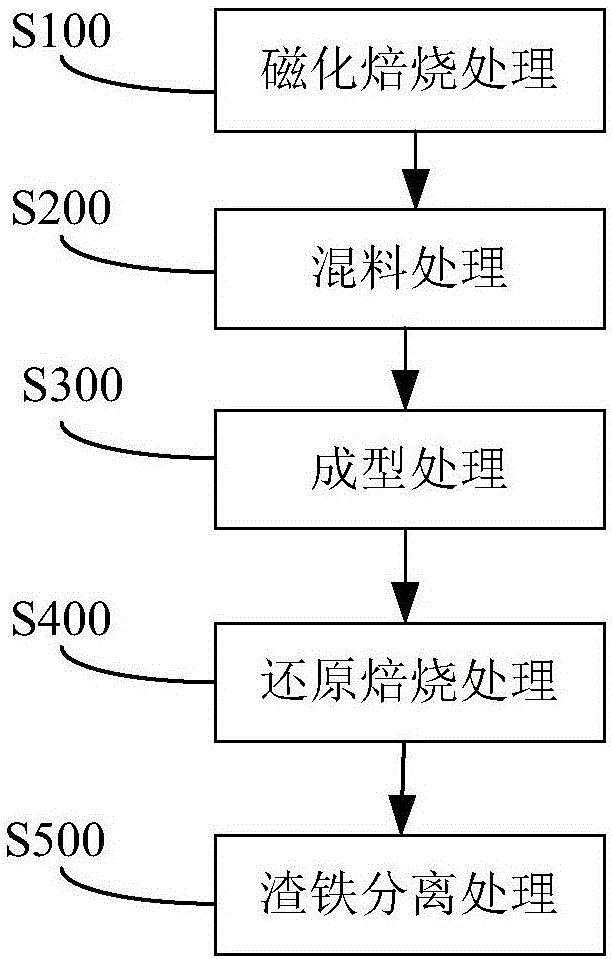

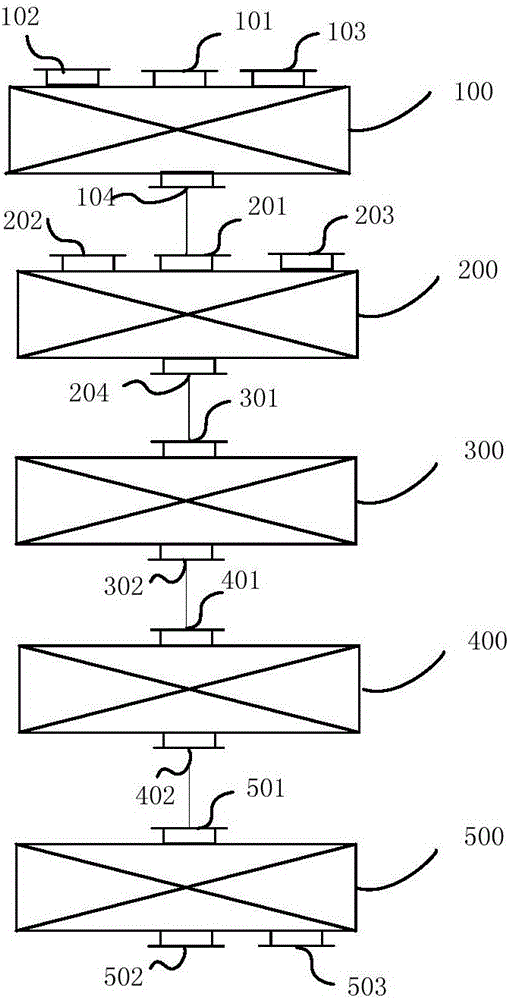

Iron preparation method and system

A vanadium titanomagnetite, inlet technology, applied in fluidized bed furnaces, furnaces, furnace types, etc., can solve the problems of easy pulverization of mineral pellets, poor reduction effect, low metal recovery rate, etc. The effect of expansion, good effect and high metallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Utilize the method of the embodiment of the present invention, take vanadium-titanium magnetite as raw material to prepare iron, wherein, the composition of vanadium-titanium magnetite: TFe59.49%, TiO 216.32%, V 2 o 5 1.04%, the specific method is as follows:

[0075] (1) Take 100 parts of vanadium-titanium magnetite ore powder, 100 mesh to 200 mesh account for 90%, and the carbon coordination coefficient is 1.05 to carry out magnetization roasting. The temperature of magnetization roasting is 900 ° C, and the roasting time is 1 hour. The whole process is under nitrogen gas. The method is carried out under the condition of protective atmosphere to obtain magnetized vanadium-titanium ore concentrate powder.

[0076] (2) Ningxia coal below 1mm is used as ingredients for mixing and pelletizing, wherein the ingredients of Ningxia coal are: 83.59% fixed carbon, 9.08% ash, 6.05% volatile matter, and 0.51% total sulfur. The material ratio is: magnetized vanadium-titanium or...

Embodiment 2

[0079] Utilize the method of the embodiment of the present invention, take vanadium titanomagnetite as raw material to prepare iron, wherein, vanadium titanomagnetite composition: TFe59.49%, TiO 2 16.32%, V 2 o 5 1.04%, the specific method is as follows:

[0080] (1) Take 100 parts of vanadium-titanium magnetite ore powder, 100 mesh to 200 mesh account for 90%, and the carbon coordination coefficient is 1.1 to carry out magnetization roasting. The temperature of magnetization roasting is 950 ° C, and the roasting time is 1.5h. The method is carried out under the condition of a nitrogen protective atmosphere to obtain magnetized vanadium-titanium ore concentrate powder.

[0081] (2) Ningxia coal below 1mm is used as ingredients for mixing and pelletizing. The ingredients of Ningxia coal are: fixed carbon 83.59%, ash content 9.08%, volatile matter 6.05%, and total sulfur 0.51%. The material ratio is: after magnetization Vanadium-titanium ore concentrate powder: coal powder: b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com