Transverse and longitudinal wave nondestructive detection method of corrugated tube internal surface and external surface longitudinal cracks

A technology of longitudinal cracks, inner and outer surfaces, used in the analysis of solids, instruments, and materials using sonic/ultrasonic/infrasonic waves. It can only detect surface and near-surface defects, and eddy current testing has low detection efficiency and is not suitable for batch testing. and other problems, to achieve the effect of short detection period, high sensitivity and great practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

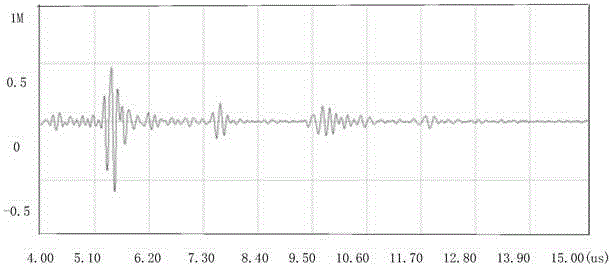

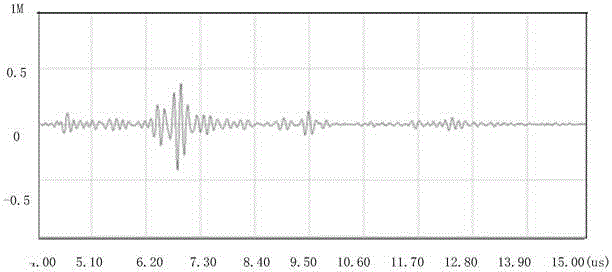

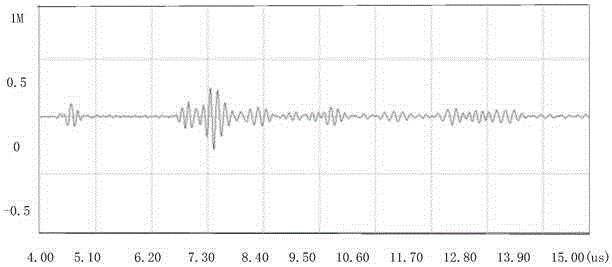

[0025] The invention provides a transverse and longitudinal wave nondestructive testing method for longitudinal cracks on the inner and outer surfaces of threaded pipes, such as figure 1 As shown, the test device used for this measurement includes a surface wave probe 2 and an industrial computer 3; the industrial computer 3 includes a data acquisition card, an ultrasonic transceiver card, a main control computer and a waveform display module; The display module is connected to the industrial computer 3; the device is used to carry out a non-destructive detection method for transverse and longitudinal waves of longitudinal cracks on the inner and outer surfaces of a threaded pipe, which is characterized in that the specific steps are as follows:

[0026] Step 1. Place the surface wave probe 2 on the preset position on the outer wall of the threaded pipe 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com