Low-acidity fruit juice fermented liquid and preparation method thereof

A fermented liquid and low-acidity technology, applied in food science and other fields, can solve problems such as poor palatability, limited effect, and low market sales, and achieve the effect of simple use, abundant resources, and easy multiplication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

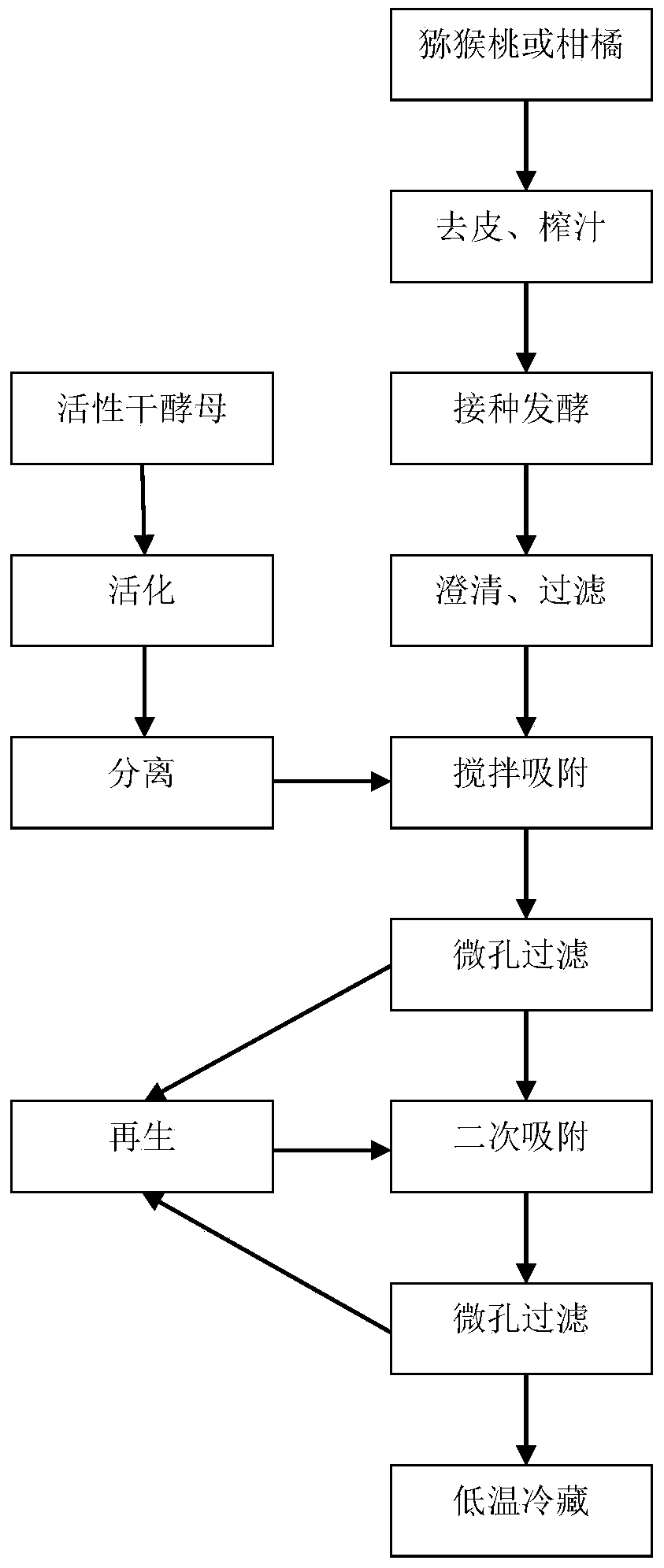

[0032] Following embodiment relates to the preparation method of low-acidity kiwi fruit or citrus fermented product, comprises the following steps:

[0033] (1) Fermentation: Inoculate kiwifruit or citrus raw materials after pretreatment such as peeling and squeezing, and ferment at constant temperature for 7-10 days, press filter and collect to obtain kiwifruit or citrus fermentation stock solution.

[0034] (2) Clarification: the fermented liquid described in step (1) is obtained by processes such as gumming and filtering to obtain a clarified fermented liquid for subsequent use.

[0035] (3) Activation: Insert the active dry yeast of brewing cerevisiae into the pre-prepared culture medium, carry out constant-temperature fermentation and expansion culture in a continuous ventilation type fermenter, and obtain yeast proliferation liquid, and set aside.

[0036] (4) Separation: After the yeast proliferation liquid described in step (3) is settled by centrifugation, the superna...

Embodiment 1

[0049] The present embodiment provides a kind of preparation method of low-acidity kiwi fruit juice fermented liquid (flow process sees figure 1 ), specifically include the following steps:

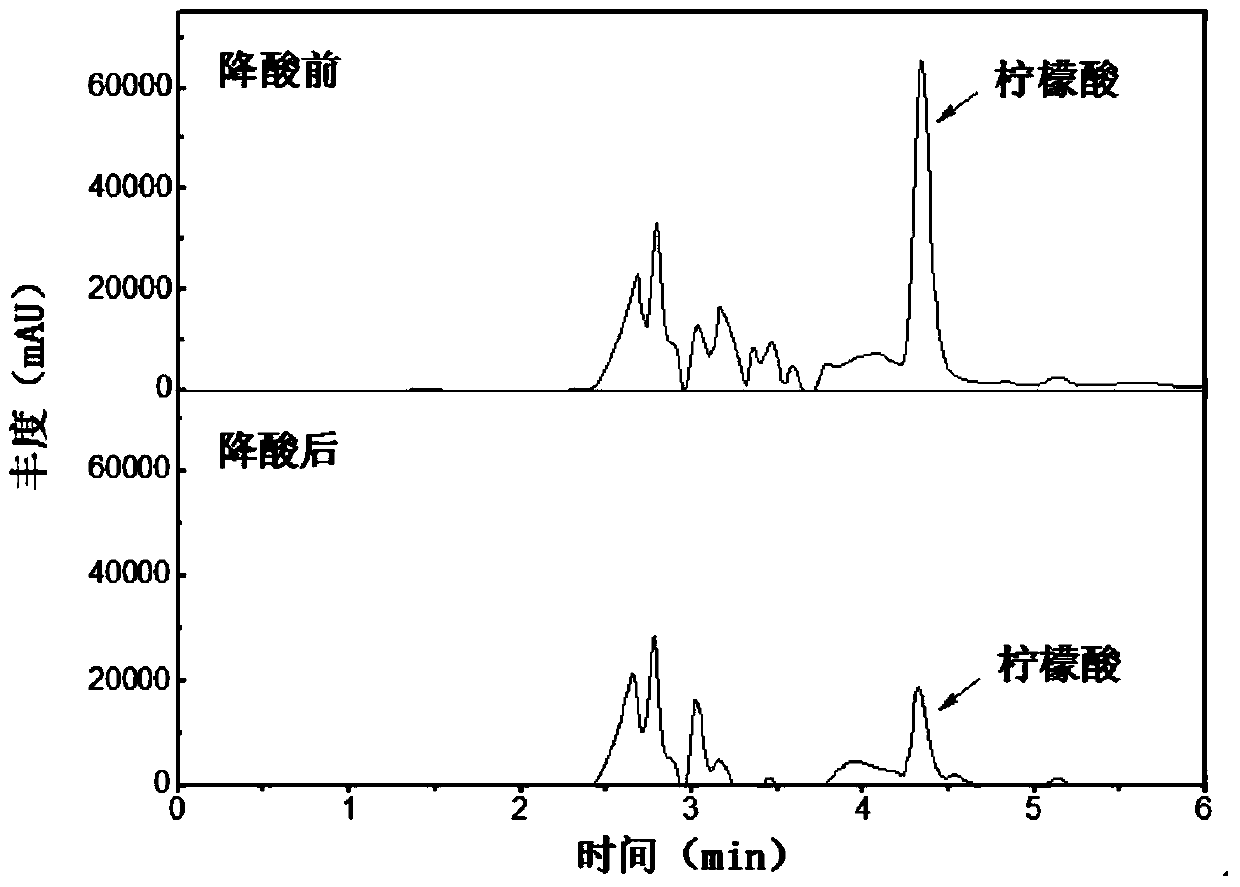

[0050] Weigh 100kg of fresh kiwi fruit, after peeling and beating, filter 75kg of kiwi fruit juice with 80-mesh gauze, add 15g of fruit wine active dry yeast, ferment at 24°C for 7 days, and filter through 200-mesh gauze to obtain kiwi fruit fermentation stock solution 58kg, add bentonite 29g and glue down and get 51kg of kiwifruit clarified fermented liquid through plate and frame filter fine filtration, record citric acid content through high performance liquid chromatography (HPLC) and be 15.16g / L (as figure 2 shown), and refrigerated at 8°C for later use.

[0051] Weigh 3.0kg of wort juice, 1.0kg of kiwi fruit fermentation stock solution, add 6.0kg of distilled water and stir well, add 0.10kg of brewing active dry yeast, activate and proliferate at 37°C for 8h, centrifuge at 3500rpm...

Embodiment 2

[0053] The present embodiment provides a kind of preparation method of low-acidity citrus juice fermented liquid (flow process sees figure 1 ), specifically include the following steps:

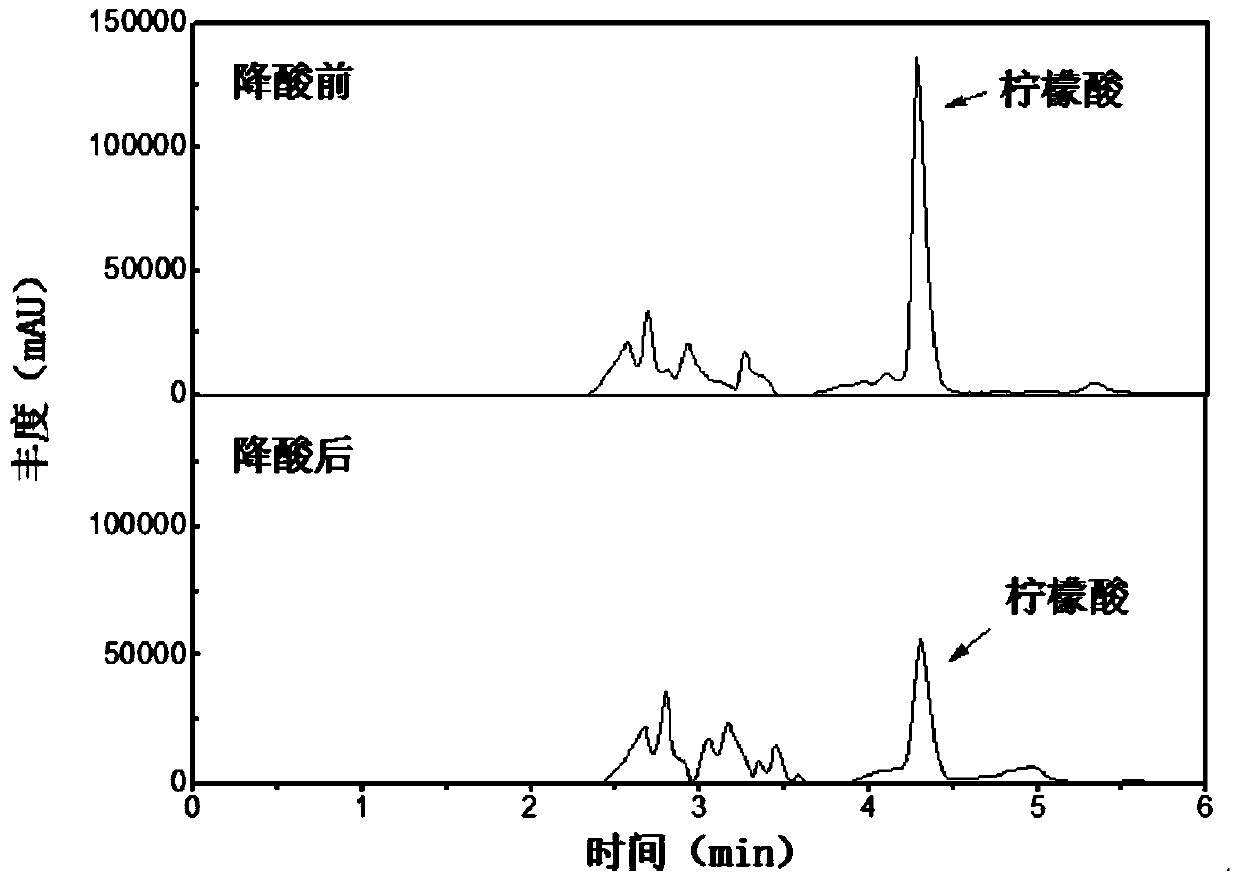

[0054] Weigh 100kg of fresh citrus fruit, after peeling and beating, filter 68kg of citrus juice with 80-mesh gauze, insert 6.8g of freeze-dried active lactic acid bacteria, ferment at 34°C for 10 days, and filter through 200-mesh gauze to obtain citrus fermentation Stock solution 60kg, after leaving standstill 48h at 4 DEG C, obtain clarification fermented liquid 54kg through plate and frame filter fine filtration, record citric acid content through high performance liquid chromatography and be 18.07g / L (as image 3 shown), and refrigerated at 8°C for later use.

[0055] Weigh 3.5kg of wort juice, 0.5kg of fermentation stock solution, add 6.0kg of distilled water and stir well, then add 0.20kg of active dry yeast for brewing wine, activate and proliferate at 37°C for 8h, centrifuge at 3500r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com