Method and device for dimethylamine waste gas treatment through aeration cooling neutralization method

A technology of dimethylamine and dimethylamine sulfate, which is applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of insufficient pump head, easy wall flow, large operating resistance, etc., and improve turbulent flow The degree and contact area, the effect of increasing the installation depth and prolonging the contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

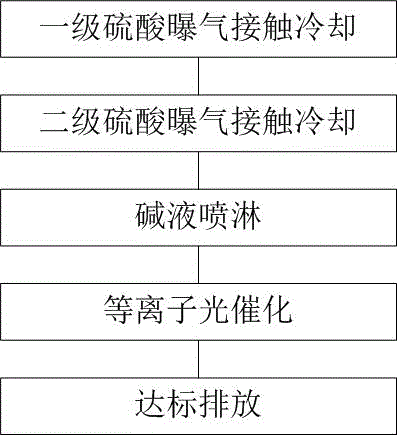

[0052] Such as figure 1 Shown, a kind of method for aeration cooling neutralization law treatment dimethylamine waste gas, comprises the steps:

[0053] (1) Primary sulfuric acid aeration contact cooling: Dimethylamine waste gas is blown by the first Roots blower into the aerator of the primary sulfuric acid aeration contact cooling tank to form dimethylamine bubbles and enters the primary sulfuric acid aeration contact cooling The tank is fully contacted with sulfuric acid, and at the same time, the sulfuric acid that is dissolving dimethylamine is cooled by the first-stage sulfuric acid aeration contact cooling coil in the tank, and the generated dimethylamine sulfate is obtained by distillation through three-effect distillation, and the remaining The exhaust gas is directed to the secondary sulfuric acid aeration contact cooling tank through the conduit;

[0054] (2) Secondary sulfuric acid aeration contact cooling: the dimethylamine waste gas that has been treated by prim...

Embodiment 2

[0059] The same as in Example 1, the difference is that the refrigerated coil is filled with circulating frozen brine, and the lye spray is a three-stage lye spray from bottom to top.

Embodiment 3

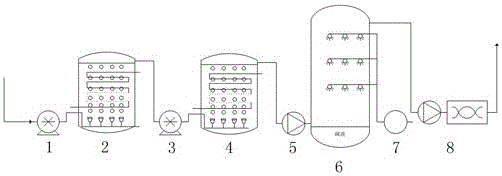

[0061] Such as figure 2 As shown, a device for aeration, cooling, neutralization and legal treatment of dimethylamine waste gas, including a primary sulfuric acid aeration contact cooling tank, a secondary sulfuric acid aeration contact cooling tank, a lye spray tower, a plasma photocatalytic integrated machine, The waste gas conveying pipe is connected to the aerator conveying pipe at the bottom of the primary sulfuric acid aeration contact cooling tank 2 through the first Roots blower 1. The top of the cooling tank is installed with the first exhaust gas conduit, which is connected to the aerator delivery pipe at the bottom of the secondary sulfuric acid aeration contact cooling tank 4 through the second Roots blower 3, and the secondary sulfuric acid aeration contact cooling tank is installed There is a circulating refrigeration coil, the top of the secondary sulfuric acid aeration contact cooling tank is equipped with a second waste gas conduit, the second waste gas condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com