Filtering membrane for endotoxin in water for dialyzate and manufacturing method of filtering membrane

A manufacturing method and dialysate technology, applied in the field of hemodialysis, can solve the problems of improvement, large liquid transmembrane resistance, unfavorable membrane permeability, etc., and achieve good liquid permeability, high mechanical strength and chemical stability, and interception. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

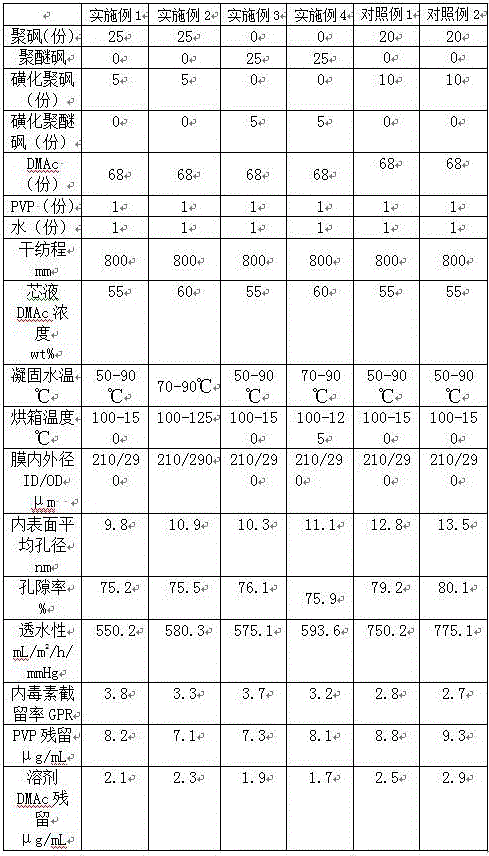

Embodiment 1

[0028] A membrane for filtering endotoxin in water for dialysate is processed from the following raw materials in proportion by mass: 25 parts of polysulfone, 5 parts of sulfonated polysulfone, 1 part of polyvinylpyrrolidone, and the solvent is selected from dimethylacetamide ( DMAc) 68 parts, water 1 part; the membrane structure of the polysulfone hollow fiber dialysis membrane is composed of a dense layer with a thickness of 3 μm on the inside and a loose layer with a thickness of 35 μm on the outside. The average pore diameter of the dense layer is 9.8 nm, and the average pore diameter of the loose layer is 95 nm. 28% of its mass in the dense layer is hydrophilic polymer, and 98% of its mass in the loose layer is polysulfone material. The surface of the dense layer is negatively charged, and the surface of the loose layer is positively charged. Among them, the sulfonated polysulfone adopts monomer sulfonation synthesis process known in the art, uses dichlorodiphenyl sulfone ...

Embodiment 2

[0031] A membrane for filtering endotoxin in water for dialysate is processed from the following raw materials in proportion by mass: 25 parts of polysulfone, 5 parts of sulfonated polysulfone, 1 part of polyvinylpyrrolidone, and the solvent is selected from dimethylacetamide ( DMAc) 68 parts, water 1 part; the membrane structure of the polysulfone hollow fiber dialysis membrane is composed of a dense layer with a thickness of 1.2 μm on the inside and a loose layer with a thickness of 31 μm on the outside. The average pore size of the dense layer is 10.9 nm, and the average pore size of the loose layer is 103 nm. 22% of the mass in the dense layer is hydrophilic polymer, and 91% of the mass in the loose layer is polysulfone material. The surface of the dense layer is negatively charged, and the surface of the loose layer is positively charged. Among them, the degree of sulfonation of sulfonated polysulfone is 20%. Its manufacturing method is as follows: select raw materials ac...

Embodiment 3

[0033] A filter membrane for endotoxin in water for dialysate, which is processed from the following raw materials in proportion by mass: 25 parts of polyethersulfone, 5 parts of sulfonated polyethersulfone, 1 part of polyvinylpyrrolidone, dimethyl ethyl ether as a solvent Amide (DMAc) 68 parts, water 1 part. The membrane structure of the polysulfone hollow fiber dialysis membrane consists of a dense layer with a thickness of 3.8 μm on the inside and a loose layer with a thickness of 36 μm on the outside. The average pore size of the dense layer is 10.3 nm, and the average pore size of the loose layer is 112 nm. In the dense layer, 25% of its mass is Hydrophilic polymer, 96% of its mass in the loose layer is polysulfone material, the surface of the dense layer is negatively charged, and the surface of the loose layer is positively charged. Among them, the degree of sulfonation of sulfonated polysulfone is 10%.

[0034] Its manufacturing method is as follows: select raw materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com