Preparation method for two-dimensional laminar heterojunction based on graphene

A two-dimensional layered and graphene technology is applied in the field of preparation of two-dimensional layered heterojunctions, which can solve the problems of poor material uniformity and complicated steps, and achieve the effects of reducing impurities, improving growth efficiency, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1, prepare graphene / boron nitride heterojunction on Pt sheet

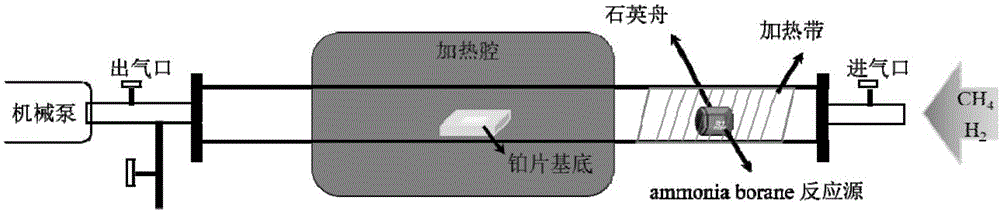

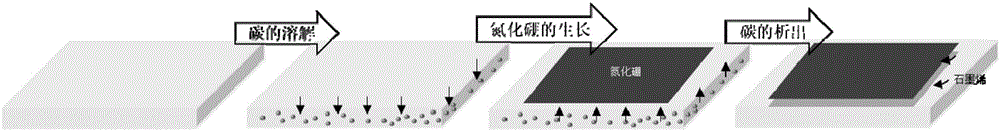

[0049] The method of the present invention prepares the CVD growth schematic diagram and the growth schematic diagram of graphene / boron nitride heterojunction respectively as follows figure 1 with figure 2 shown.

[0050] Base preparation:

[0051] Cut a Pt sheet of appropriate size as a substrate, and use acetone, alcohol, and deionized water for ultrasonic cleaning in order to remove impurities and organic matter on the surface.

[0052] Fabrication of graphene / boron nitride heterojunction:

[0053] First, weigh 3 mg of ammonia borane and place it in a U-shaped quartz boat with one end closed; put the prepared Pt sheet (3cm×3cm) and ammonia borane reaction source into the CVD quartz tube, and the position of the Pt sheet is for heating In the middle of the area, the position of the ammonia borane source is 35cm away from the Pt sheet at the inlet end; secondly, vacuumize the quartz tube to ...

Embodiment 2

[0063] Embodiment 2, prepare graphene / boron nitride heterojunction on Cu-Ni alloy

[0064] Because the carbon solubility of Cu-Ni alloy and Pt is different, the preparation parameters are adjusted, mainly the flow rate of methane and the cooling process.

[0065] According to the preparation method in Example 1, the same preparation process is adopted, except that in the process of carbon dissolution, CH 4 :H 2 The ratio is 5sccm: 10sccm; in addition, in the final carbonization step, the temperature is slowly lowered to 900°C at a rate of 26°C / min and then rapidly lowered.

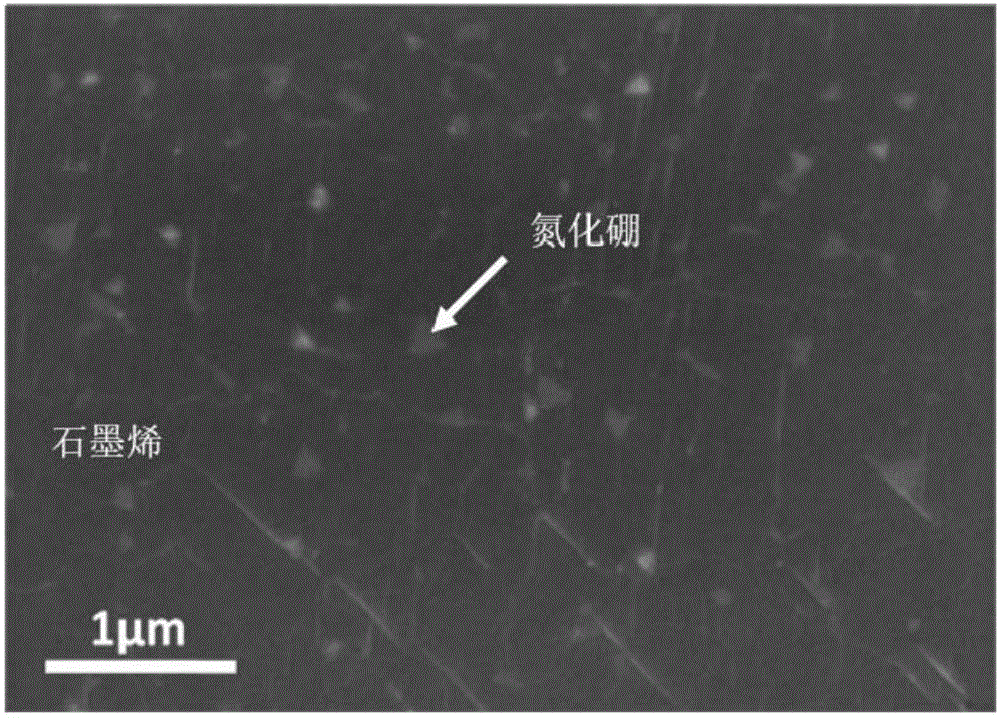

[0066] The SEM image of the graphene / boron nitride heterojunction prepared in this embodiment is as follows Figure 10 Shown, as can be seen from this figure, are sub-monolayer boron nitride (dark quadrilaterals) and monolayer graphene.

[0067] The optical picture of the graphene / boron nitride heterojunction prepared in this embodiment is as follows Figure 11 As shown, it can be seen from the figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com