A kind of quaternary ammonium salt perrhenate ionic liquid and its synthesis method and application

A technology of ionic liquid and perrhenate, which is applied in the fields of application, chemical instruments and methods, sugar production, etc., and can solve problems such as catalysts that have not been prepared

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

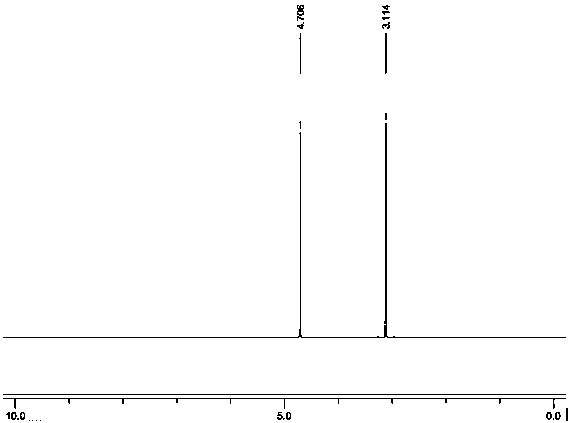

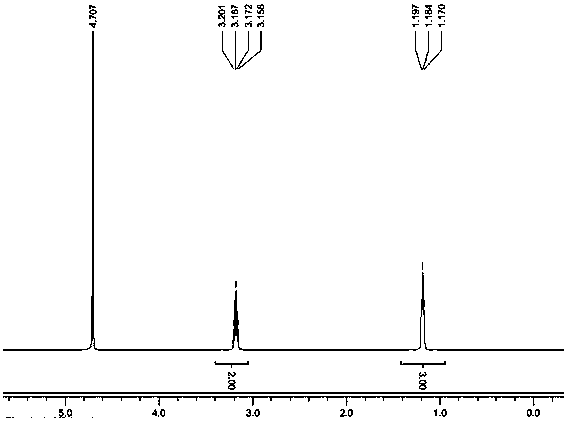

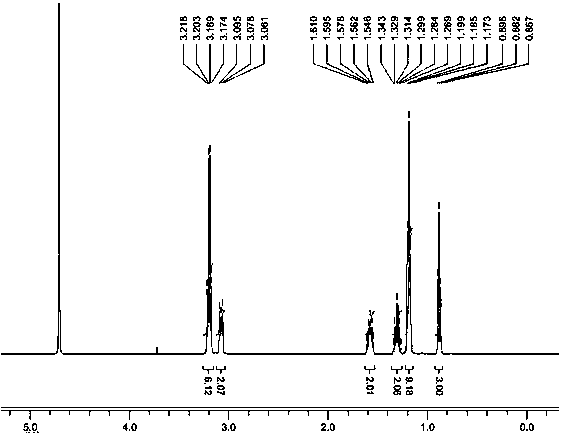

Image

Examples

Embodiment 1

[0027] Dissolve tetramethylammonium bromide and KOH in a certain amount of absolute ethanol solution respectively, wherein the molar ratio of tetramethylammonium bromide and KOH is 1:1.1, stir and react at room temperature for 12 hours, white potassium bromide Precipitation, filtration to remove potassium bromide precipitate, to obtain tetramethyl quaternary ammonium base ethanol solution. Add NH to the ethanol solution of the obtained tetramethylquaternary ammonium base 4 ReO 4 , where the quaternary ammonium base and NH 4 ReO 4 The molar ratio is 1:1.1, heated to 60°C for gentle reflux for 1h (use pH test paper to check whether ammonia gas is released), then lower the temperature to room temperature and stir for 24h, white solids (tetramethylperrhenic acid) are continuously precipitated Ammonium is insoluble in ethanol), after the reaction is completed, filter to obtain a white solid, wash with distilled water, and then dry in a vacuum oven at 40°C for 6 hours to obtain p...

Embodiment 2

[0029] Dissolve tetraethylammonium bromide and KOH in a certain amount of absolute ethanol solution respectively, wherein the molar ratio of tetraethylammonium bromide and KOH is 1:1.1, stir and react at room temperature for 10 h, white bromide Potassium is precipitated, and the potassium bromide precipitate is removed by filtration to obtain an ethanol solution of tetraethyl quaternary ammonium base. Add NH to the obtained ethanol solution of tetraethylammonium base 4 ReO 4 , where the quaternary ammonium base and NH 4 ReO 4 The molar ratio is 1:1.1, heated to 50°C for gentle reflux for 1.5h (use pH test paper to check whether ammonia gas is released), then lower the temperature to room temperature and stir for 24 h, filter after the reaction to remove excess perrhenium Ammonium perrhenate and potassium perrhenate produced by the reaction with KOH remaining in the solution, the filtrate was removed by a rotary evaporator to remove most of the ethanol solution, and then dri...

Embodiment 3

[0031] Dissolve 1-butyl(triethyl)ammonium bromide and KOH in a certain amount of absolute ethanol solution respectively, wherein the molar ratio of 1-butyl(triethyl)ammonium bromide to KOH is 1:1.1, The reaction was stirred at room temperature for 15 h, and the potassium bromide precipitate was removed by filtration to obtain an ethanol solution of butyl triethyl quaternary ammonium base. Add NH4ReO to the ethanol solution of the obtained butyltriethylammonium base 4 , where the quaternary ammonium base and NH 4 ReO 4 The molar ratio is 1:1.1, heated to 70 ℃ for gentle reflux for 0.5h (use pH test paper to check whether ammonia gas is released), then lower the temperature to room temperature and stir for 24h, filter after the reaction to remove excess perrhenic acid Ammonium and the potassium perrhenate produced by the reaction with KOH remaining in the solution, the filtrate was removed by a rotary evaporator to remove most of the ethanol solution, and then dried in a vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com