Cold-feeling composite material, preparation method thereof and application

A composite material, cold-feeling technology, applied in the application, fiber type, clothing and other directions, can solve the problems of unsuitable bra, rash, local stuffiness, etc., to achieve easy product production and circulation, reduce production costs, and moderate thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

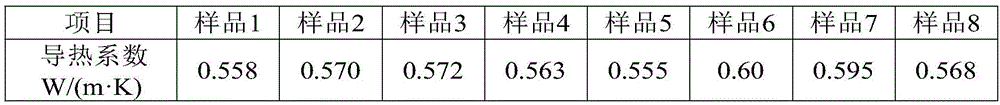

Examples

Embodiment 1

[0027] A cold-sensing composite material, the raw materials and parts by weight for preparing the cold-sensing composite material are: 60 parts of aloe liquid, 8 parts of ethylene glycol, 3.0 parts of peppermint, 2.0 parts of magnesium stearate, 1.0 parts of aluminum sulfate, coconut 1.0 parts of oleic acid diethanolamide, 1.0 parts of ferrous chloride, and 80 parts of ethanol solution with a mass fraction of 5%. Wherein the mint is in granular form with a particle size of 3 μm.

Embodiment 2

[0029] A cold-sensing composite material, the raw materials and parts by weight for preparing the cold-sensing composite material are: 80 parts of Polygonatum Polygonatum Liquid, 6 parts of ethylene glycol, 7 parts of sugar alcohol, 5 parts of raw land, 2 parts of sodium carbonate, stearin 3.0 parts of magnesium sulfate, 2.0 parts of aluminum sulfate, 2.0 parts of polyvinylpyrrolidone, 2.0 parts of sodium chloride, and 100 parts of ethanol solution with a mass fraction of 15%. Among them, the habitat is granular, with a particle size of 5 μm.

Embodiment 3

[0031] A cold-sensing composite material, the raw materials and parts by weight for preparing the cold-sensing composite material are: 70 parts of lily liquid, 5 parts of glycerin, 5 parts of ethylene glycol, 5.0 parts of viola chinensis, 2.5 parts of magnesium stearate, 1.5 parts of aluminum sulfate, 1 part of coconut acid diethanolamide, 0.5 parts of polyvinylpyrrolidone, 0.8 parts of ferrous chloride, 0.7 parts of sodium chloride, and 90 parts of ethanol solution with a mass fraction of 10%. Among them, Viola ditin is granular, with a particle size of 2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com