Receptor-modified and receptor-free titanium dioxide nano metal film Raman chips and manufacturing method

A nano-metal film and titanium dioxide technology, applied in Raman scattering, material excitation analysis, etc., can solve the problems of large absolute quantitative analysis error, poor consistency and stability, and harsh requirements for the production of silver particle film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

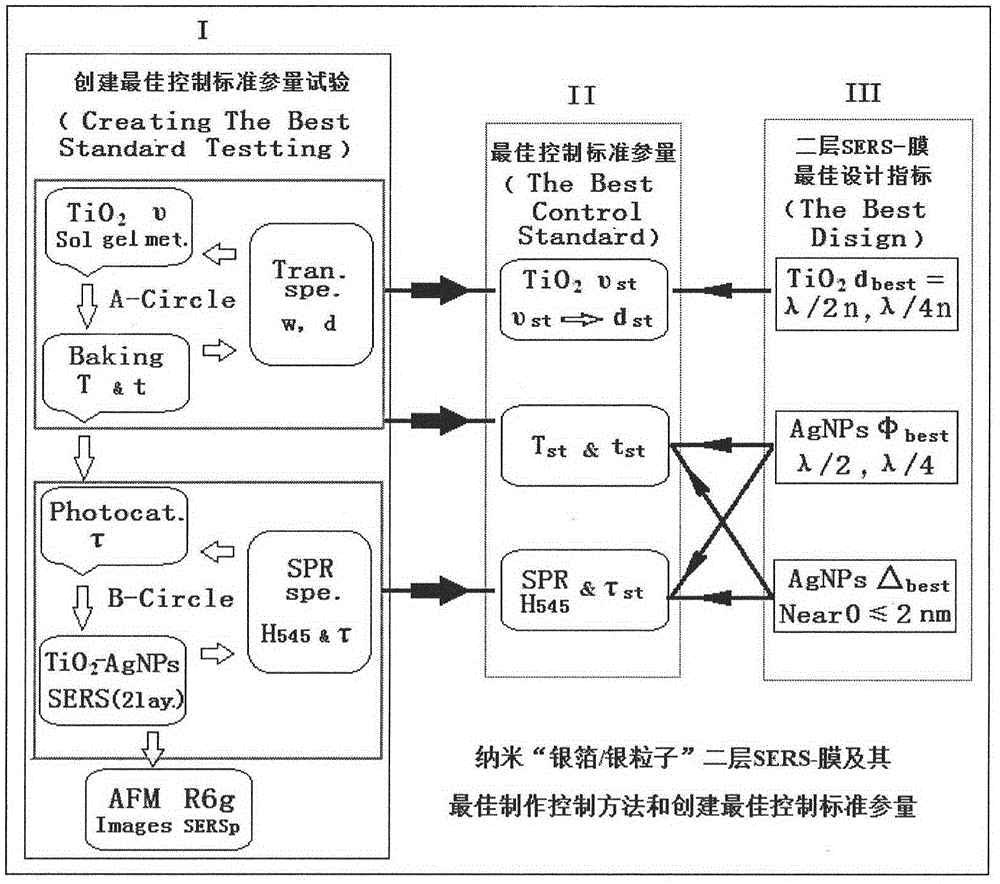

Method used

Image

Examples

Embodiment Construction

[0027] 1. The specific implementation method of the capillary-type titanium dioxide nano-metal film Raman chip with or without acceptors

[0028] For the structure of the capillary Raman chip see Figure 6 , coated with TiO in the capillary (1) 2 Membrane (2), TiO 2 Nano "silver foil / silver particles" film (3) is grown on the film, and the acceptor molecular film (4) is modified on the film, and there are very fine engravings near both ends of the capillary inlet and outlet sealing sections (5). Before using the chip, it can be conveniently broken, opened, and spared at the mark at this moment; the specific implementation method of the capillary Raman chip is as follows:

[0029]Step 1: Clean the hard neutral glass or quartz glass capillary, with an inner diameter of about 0.5mm, an outer diameter of 1.0mm, and a length of 100mm;

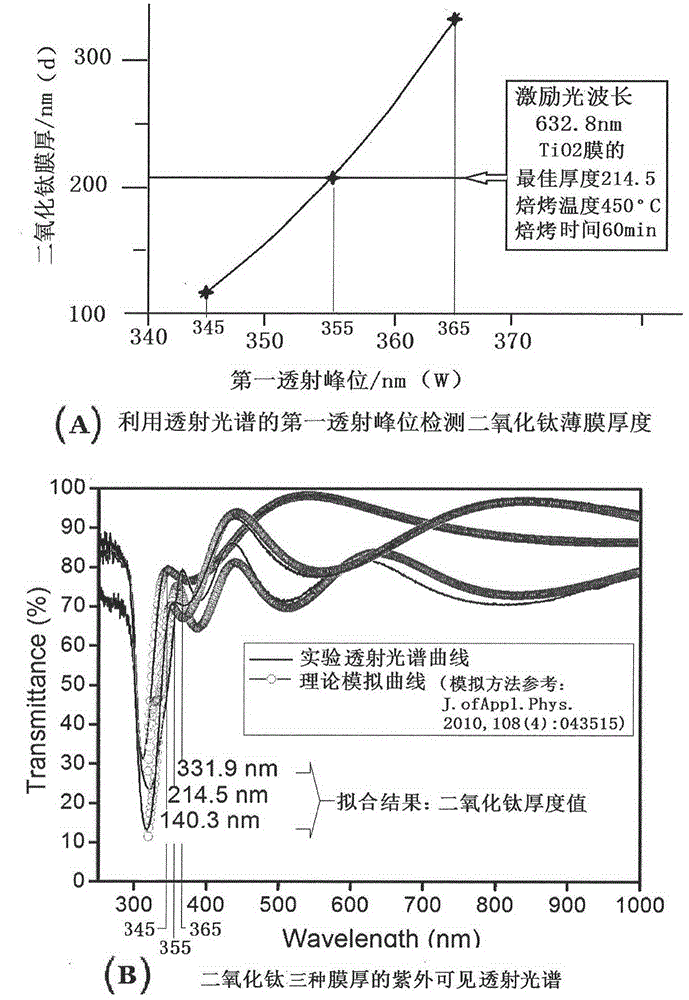

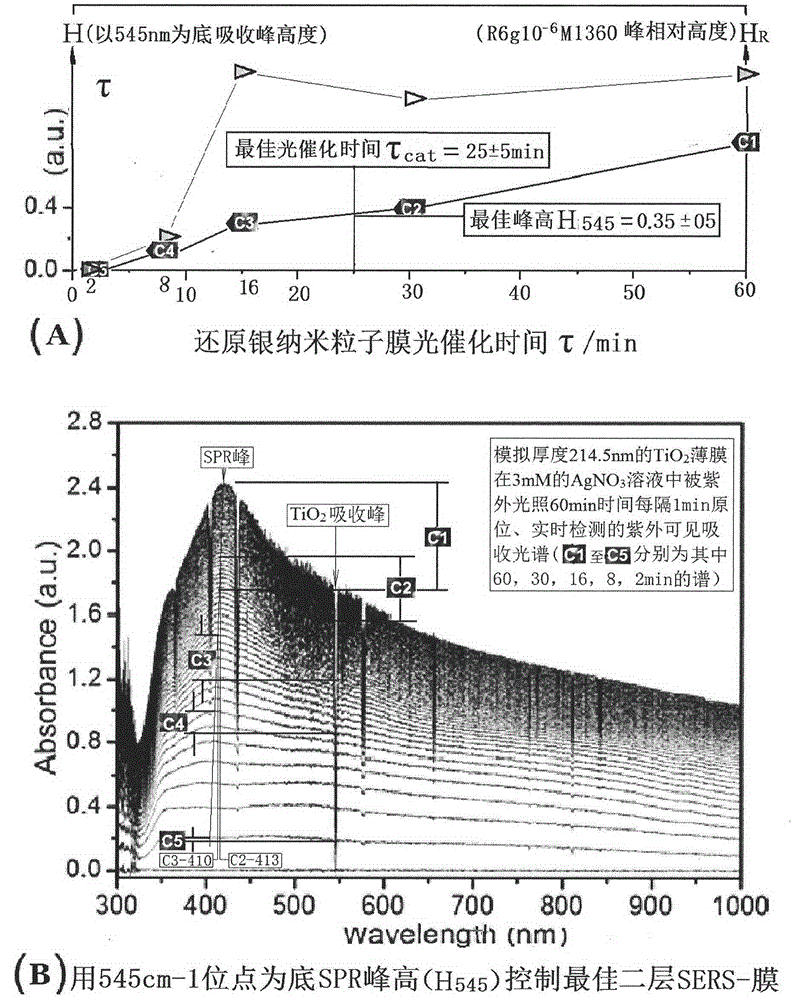

[0030] Step 2: Preparation of TiO 2 Sol: 50mL of butyl titanate and 3mL of acetylacetone were mixed and stirred for 10min (referred to as solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com