Dimming function film, dimming function assembly and dimming function device

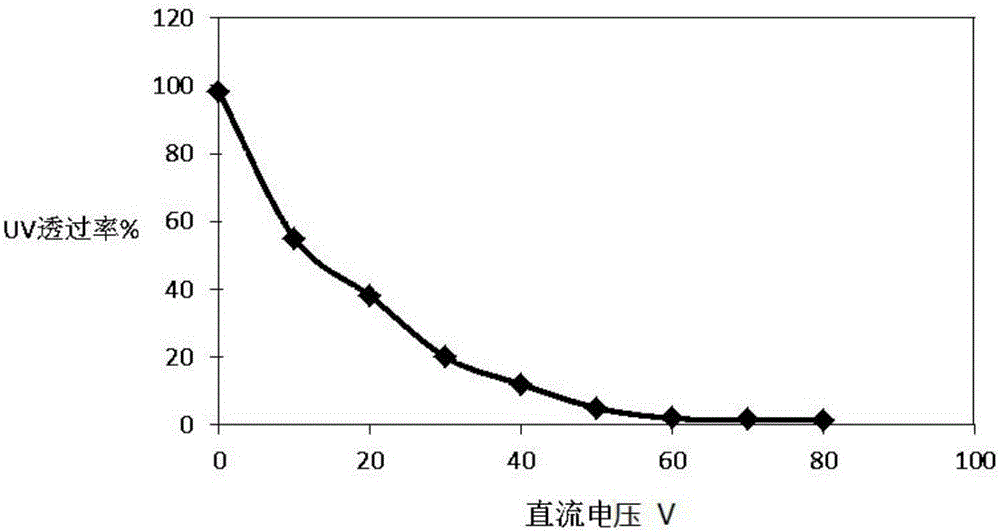

A technology of functional components and functional films, applied in optics, instruments, nonlinear optics, etc., can solve problems such as the inability to effectively control the passage of ultraviolet rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

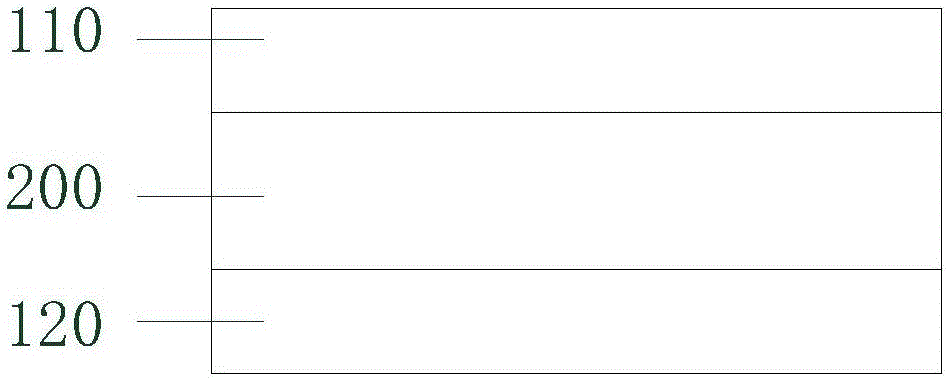

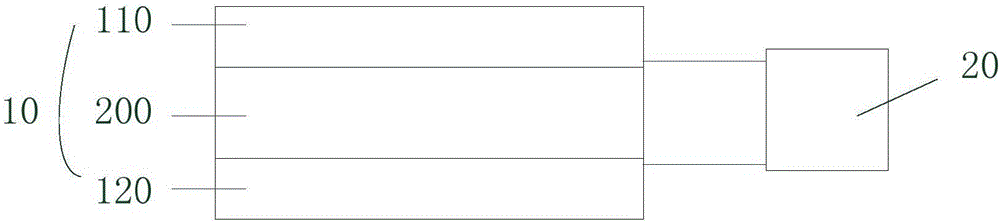

[0053] In this embodiment, a dimming functional film is prepared, and its preparation method is as follows:

[0054] Fix two rolls of ITO film on the coating machine; secondly, drop the pre-prepared polymer-dispersed liquid crystal substrate containing viologen compound to be cured slurry evenly between the two layers of ITO film, and adjust the roller pressure wheel Pressure value, at a speed of 1m / min, the coating is completed at a uniform speed, and finally passed through the UV curing machine, after the light intensity (100 ~ 500mj / cm 2 ) cured by ultraviolet radiation to form a dimming functional layer.

[0055] The raw material components and dosage of the dimming functional layer are as follows:

[0056]

[0057] The above-mentioned liquid crystal has a molecular weight of 280, a refractive index of 1.435, a dielectric coefficient of 10, a clearing point of 80°C, an optical anisotropy Δn of 0.261, and a viscosity of 53; the square resistance of the ITO film is 350Ω / ...

Embodiment 2

[0069] In this embodiment, a dimming functional film is prepared, and its preparation method is as follows:

[0070] Fix two rolls of ITO film on the coating machine; secondly, drop the pre-prepared polymer-dispersed liquid crystal substrate containing viologen compound to be cured slurry evenly between the two layers of ITO film, and adjust the roller pressure wheel Pressure value, at a speed of 1m / min, the coating is completed at a uniform speed, and finally passed through the UV curing machine, after the light intensity (100 ~ 500mj / cm 2 ) cured by ultraviolet radiation to form a dimming functional layer.

[0071] The raw material components and dosage of the dimming functional layer are as follows:

[0072]

[0073] The above-mentioned liquid crystal has a molecular weight of 280, a refractive index of 1.435, a dielectric coefficient of 10, a clearing point of 80°C, an optical anisotropy Δn of 0.261, and a viscosity of 53; the square resistance of the ITO film is 350Ω / ...

Embodiment 3

[0084] In this embodiment, a dimming functional film is prepared, and its preparation method is as follows:

[0085] Fix two rolls of ITO film on the coating machine; secondly, drop the pre-prepared polymer-dispersed liquid crystal substrate containing viologen compound to be cured slurry evenly between the two layers of ITO film, and adjust the roller pressure wheel Pressure value, at a speed of 1m / min, the coating is completed at a uniform speed, and finally passed through the UV curing machine, after the light intensity (100 ~ 500mj / cm 2 ) cured by ultraviolet radiation to form a dimming functional layer.

[0086] The raw material components and dosage of the dimming functional layer are as follows:

[0087]

[0088] The above-mentioned liquid crystal has a molecular weight of 280, a refractive index of 1.435, a dielectric coefficient of 10, a clearing point of 80°C, an optical anisotropy Δn of 0.261, and a viscosity of 53; the square resistance of the ITO film is 350Ω / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| isotropization temperature | aaaaa | aaaaa |

| isotropization temperature | aaaaa | aaaaa |

| isotropization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com