Semiconductor structure forming method

A semiconductor and nucleation layer technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems that the performance of aluminum-titanium work function layer needs to be improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

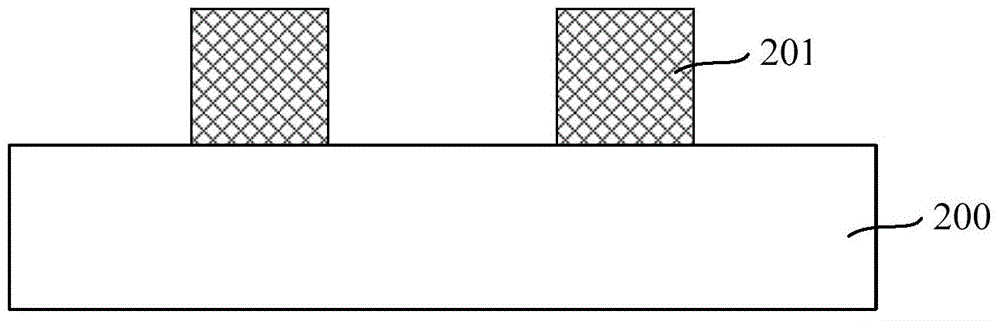

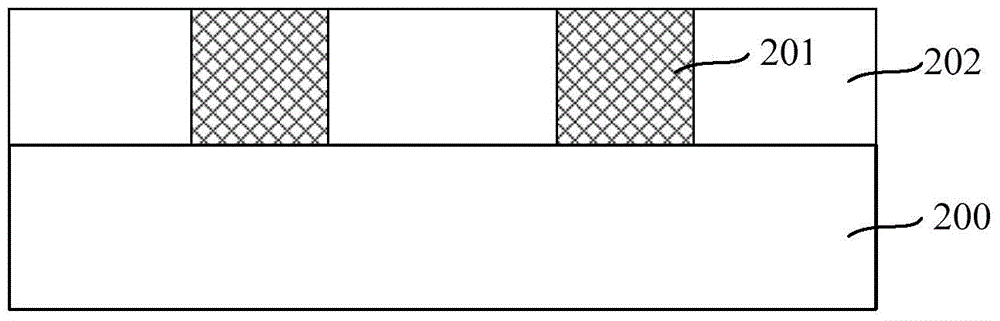

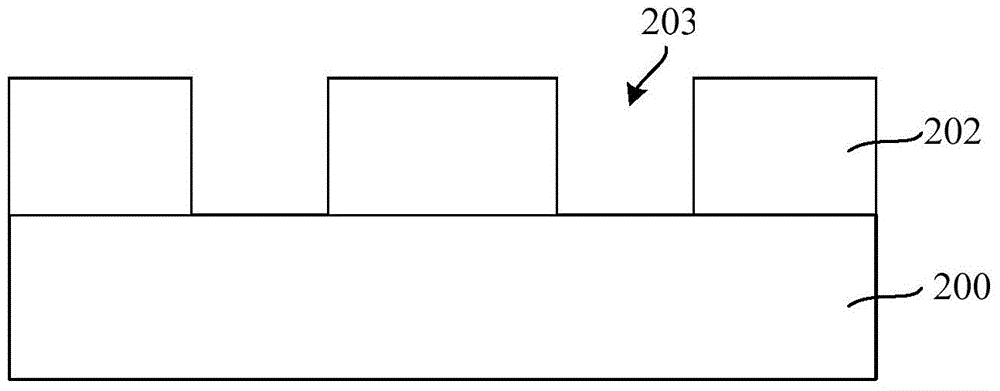

[0042] As mentioned in the background art, the performance of the aluminum-titanium work function layer formed in the existing metal gate process still needs to be improved. For example, the aluminum-titanium work function layer has problems of rough surface and poor thickness uniformity, which affects the electrical performance of the formed transistor.

[0043] Research has found that in the prior art, the aluminum-titanium work function layer is formed through a deposition process, and the aluminum-titanium work function layer is directly formed on the surface of the high-K gate dielectric layer or the diffusion barrier layer. The contact angle of the barrier layer material is relatively large. When the Al-Ti work function layer is formed by the deposition process, the nucleation on the surface of the high-K gate dielectric layer or the diffusion barrier layer is discontinuous, so that the surface of the finally formed Al-Ti work function layer will be larger. rough.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com