Gas separation film based on carbon nanotube/graphene oxide-polyether block amide

A polyether block amide and gas separation membrane technology, applied in the field of membrane separation, can solve problems such as unfavorable gas separation performance, graphene oxide is easy to wrinkle, etc., and achieves the effects of high gas permeability coefficient and separation coefficient, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

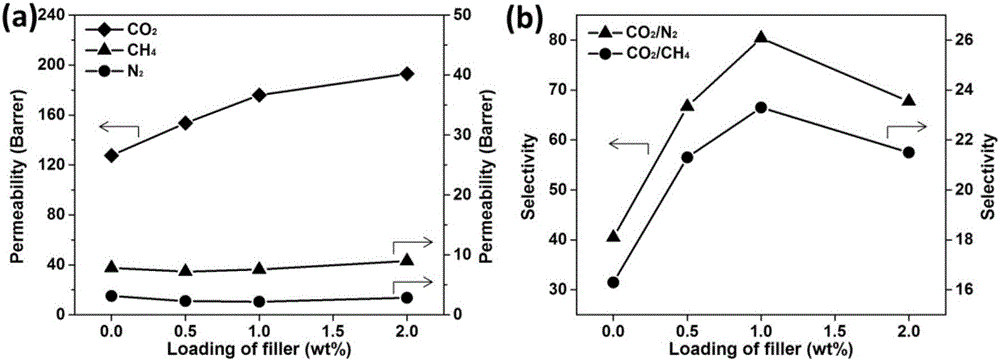

[0017] Embodiment 1, disperse 300 milligrams of oxidized carbon nanotubes in 80 milliliters of concentrated sulfuric acid with a concentration of 16mol / L, after stirring evenly, add 8 milliliters of phosphoric acid, and stir for 20 minutes; 1 gram of potassium permanganate is added to step (1 ) in the mixed solution described in ), stirred for 1 hour, then stirred at 60 ° C for 2 hours; dissolved in (2) was added to 100 ml of ice containing 5% hydrogen peroxide, and after standing for 24 hours, remove the above clear liquid; the solution in (3) is cleaned with 30% hydrochloric acid, then the product is dissolved in 60 milliliters of 30% hydrochloric acid, and after standing for 12 hours, it is cleaned to neutral by suction filtration to obtain carbon nanotube / graphene oxide; A certain amount of carbon nanotubes / graphene oxide prepared in a certain amount of steps (1)-(4) is ultrasonically dispersed in a mixed solution of ethanol and water (mass ratio 7:3), to obtain a uniform d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com