Alprostadil freeze-dried microemulsion, raw material composition and preparation method of alprostadil freeze-dried microemulsion

A raw material composition, the technology of alprostadil is applied in the directions of pharmaceutical formulations, emulsion delivery, medical preparations containing active ingredients, etc. problems, to achieve the effect of reducing the risk of blood embolism, convenient storage and transportation, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

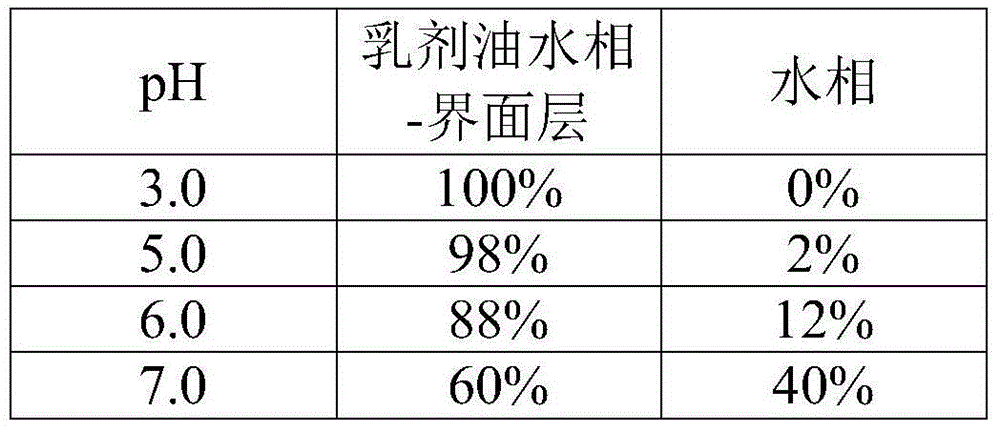

Image

Examples

Embodiment 1

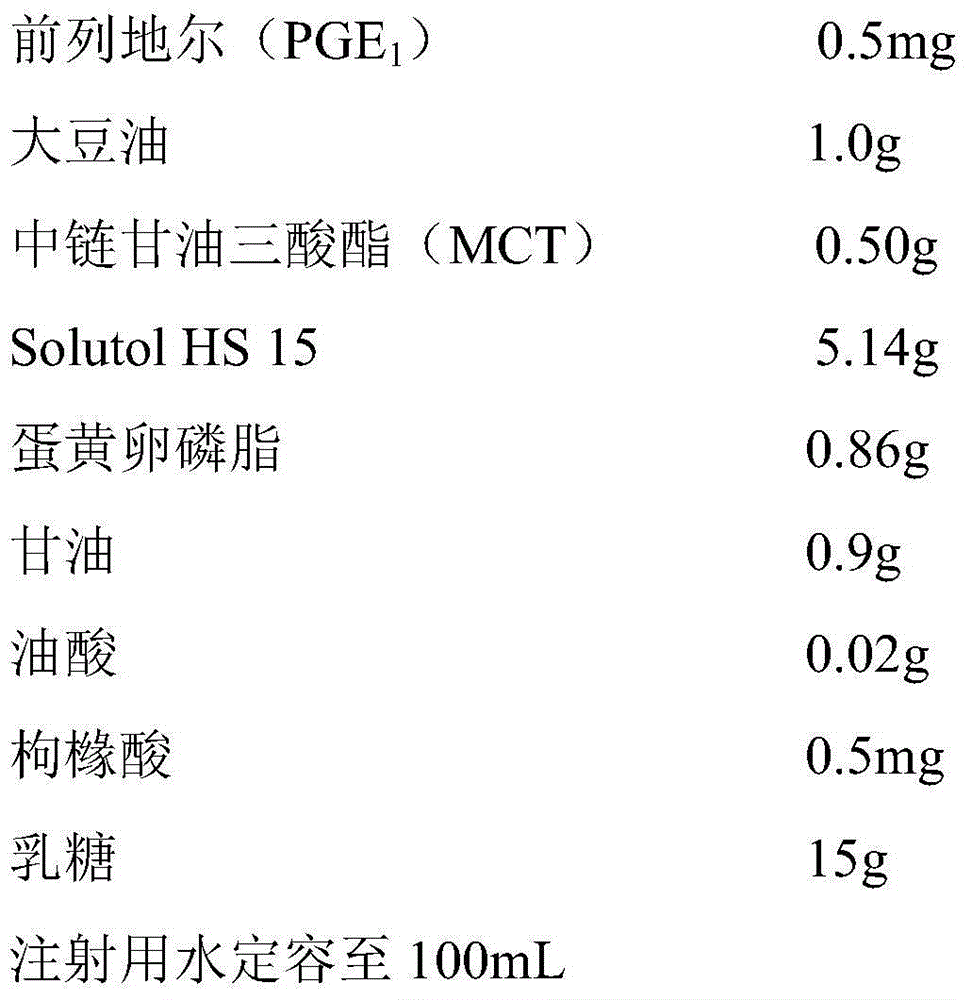

[0051] A kind of raw material composition of alprostadil freeze-dried microemulsion, its component and content are as follows:

[0052]

[0053] The preparation method of the alprostadil freeze-dried microemulsion of the present embodiment comprises the steps:

[0054] (1) Under nitrogen atmosphere, mix soybean oil, MCT, Solutol HS 15, egg yolk lecithin, glycerin and oleic acid according to the above formula, heat and dissolve at 40°C, then add alprostadil to it, dissolve and mix to obtain oil phase; mix lactose with 80mL water for injection, stir and dissolve to obtain the water phase;

[0055] (2) Under a nitrogen atmosphere, add the obtained water phase dropwise into the oil phase at a rate of 0.5 mL / min, and emulsify at 50-60° C. using Fluko shear conditions to obtain a microemulsion;

[0056] (3) Under a nitrogen atmosphere, adjust the pH of the obtained microemulsion to 4.5 with citric acid, then dilute it to 100 mL with water for injection, then perform sterile filt...

Embodiment 2

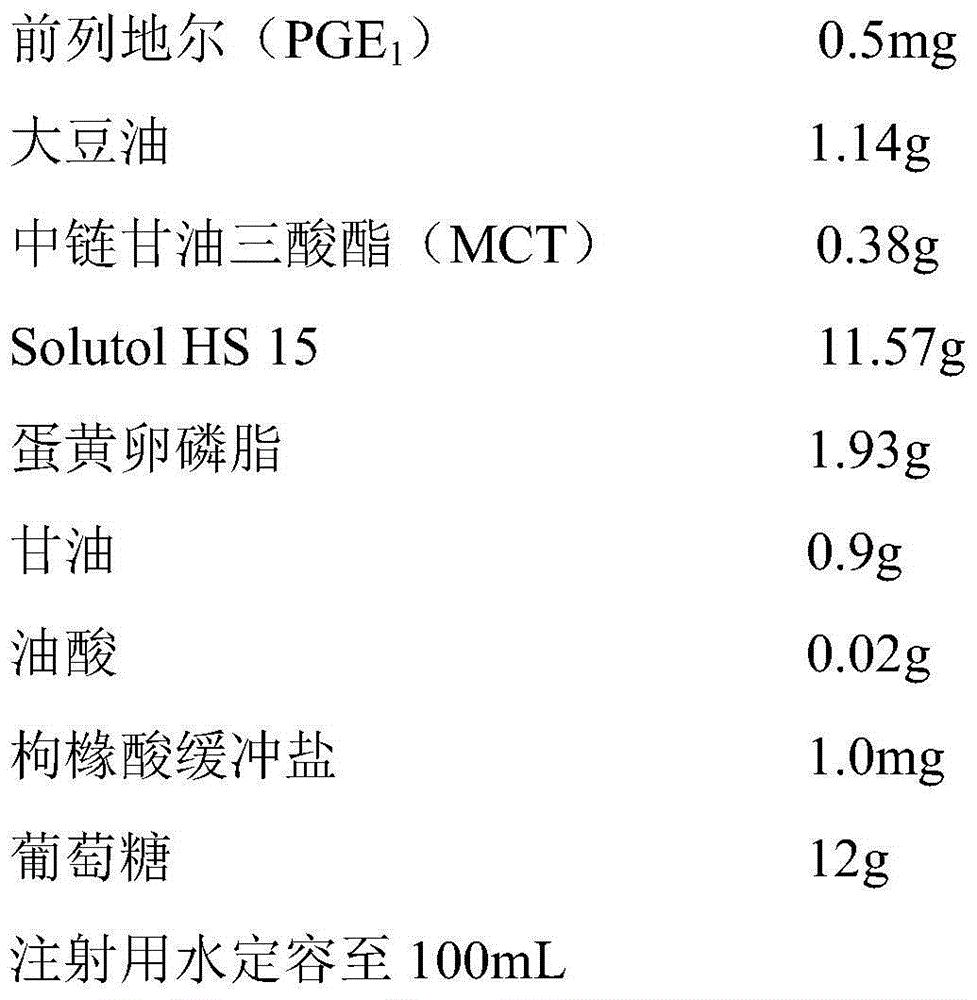

[0058] A kind of raw material composition of alprostadil freeze-dried microemulsion, its component and content are as follows:

[0059]

[0060] The preparation method of the alprostadil freeze-dried microemulsion of the present embodiment comprises the steps:

[0061] (1) Under nitrogen atmosphere, mix soybean oil, MCT, Solutol HS 15, egg yolk lecithin, glycerin and oleic acid according to the above formula, heat and dissolve at 25°C, then add alprostadil to it, dissolve and mix to obtain oil phase; glucose was mixed with 60mL water for injection, stirred and dissolved to obtain the aqueous phase;

[0062] (2) Under a nitrogen atmosphere, add the obtained water phase dropwise into the oil phase at a rate of 1.0 mL / min, emulsify at 40-45° C. using Fluko shear conditions to obtain a microemulsion;

[0063] (3) Under a nitrogen atmosphere, adjust the pH of the obtained microemulsion to 5.0 with citrate buffered salt, then dilute it to 100 mL with water for injection, and the...

Embodiment 3

[0065] A kind of raw material composition of alprostadil freeze-dried microemulsion, its component and content are as follows:

[0066]

[0067] The preparation method of the alprostadil freeze-dried microemulsion of the present embodiment comprises the steps:

[0068] (1) Under a nitrogen atmosphere, mix soybean oil, MCT, Solutol HS 15, egg yolk lecithin, glycerin and sodium oleate according to the above formula, heat and dissolve at 50°C, then add alprostadil to it, dissolve and mix to obtain Oil phase; mix sucrose with 80mL water for injection, stir and dissolve to obtain the water phase;

[0069] (2) Under a nitrogen atmosphere, the obtained water phase was added dropwise to the oil phase at a rate of 1.5 mL / min, and emulsified at 30-50° C. using Fluko shear conditions to obtain a microemulsion;

[0070] (3) Under a nitrogen atmosphere, adjust the pH of the obtained microemulsion to 5.2 with citrate buffered salt, then dilute it to 100 mL with water for injection, then p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com