System for separating oxygen and oxygen from air based on variable-frequency negative-pressure method

A technology of nitrogen and oxygen separation and negative pressure method, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of pressure redundancy, energy waste, affecting separation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

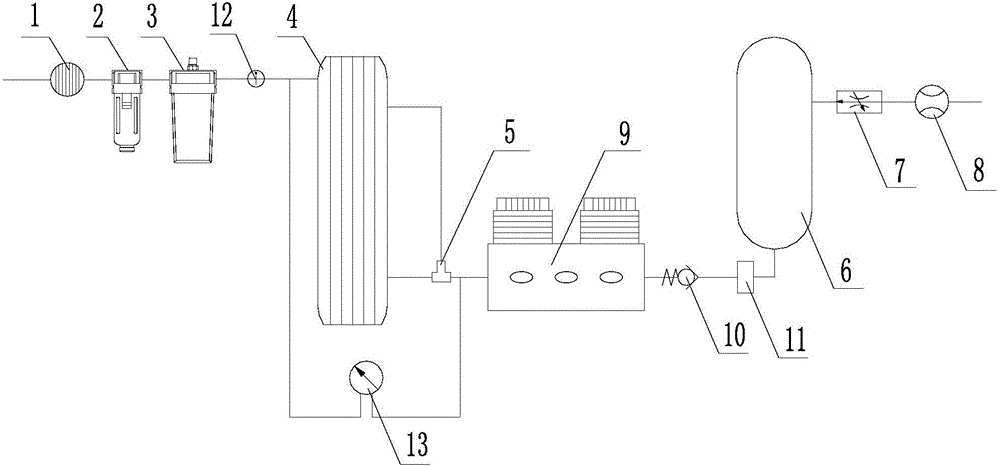

[0021] Such as figure 1 as shown, figure 1 The invention proposes a system for realizing the separation of air nitrogen and oxygen based on the frequency conversion negative pressure method.

[0022] refer to figure 1 , the system proposed by the present invention based on the frequency conversion negative pressure method to realize the separation of air, nitrogen and oxygen includes: a gas processing unit, a gas separation unit, and a main control unit;

[0023] The gas processing unit comprises a primary filter device 1, a fine filter device 2, and a drying device 3; the air inlet of the primary filter device 1 communicates with the air outlet, and the gas outlet of the primary filter device 1 communicates with the air inlet of the fine filter device 2, The air outlet of the fine filter device 2 communicates with the air inlet of the drying device 3;

[0024]The gas separation unit comprises a hollow fiber membrane 4, a gas storage tank 6, an electronically controlled thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com