A kind of microsphere with Raman activity and preparation method thereof

A technology of Raman activity and microspheres, which is applied in the fields of biological monitoring and medical treatment, and can solve the problems of low signal enhancement effect, unobtainable, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

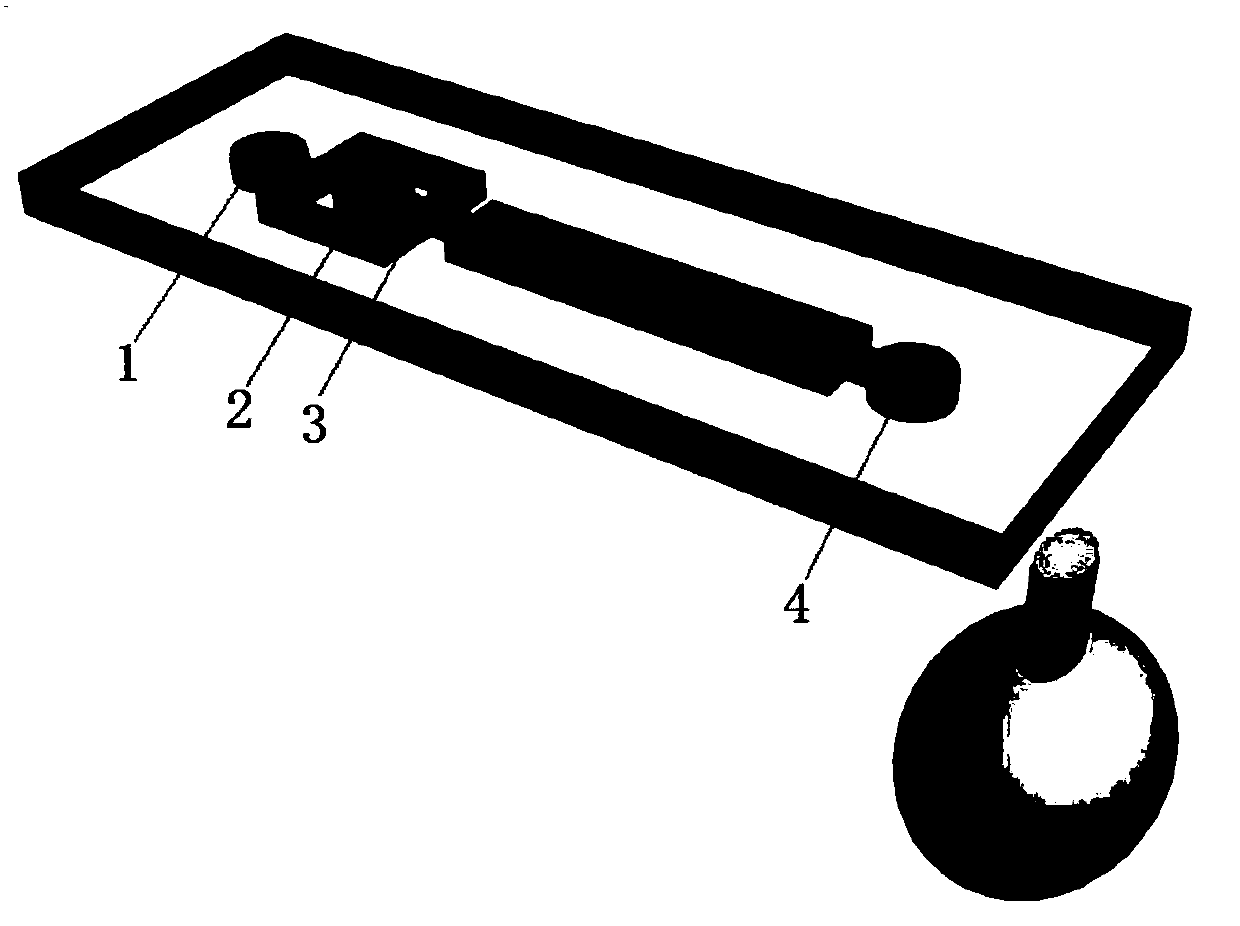

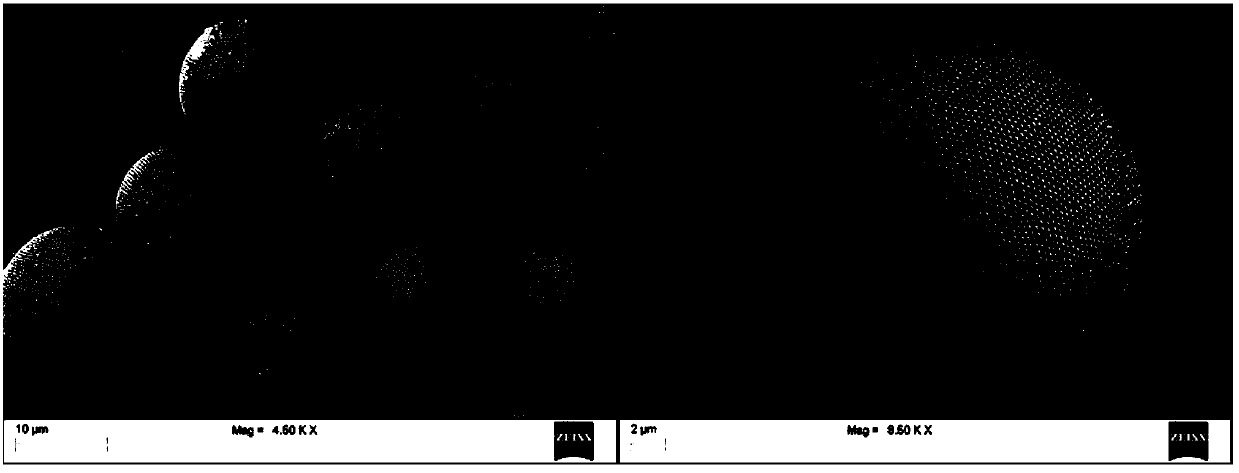

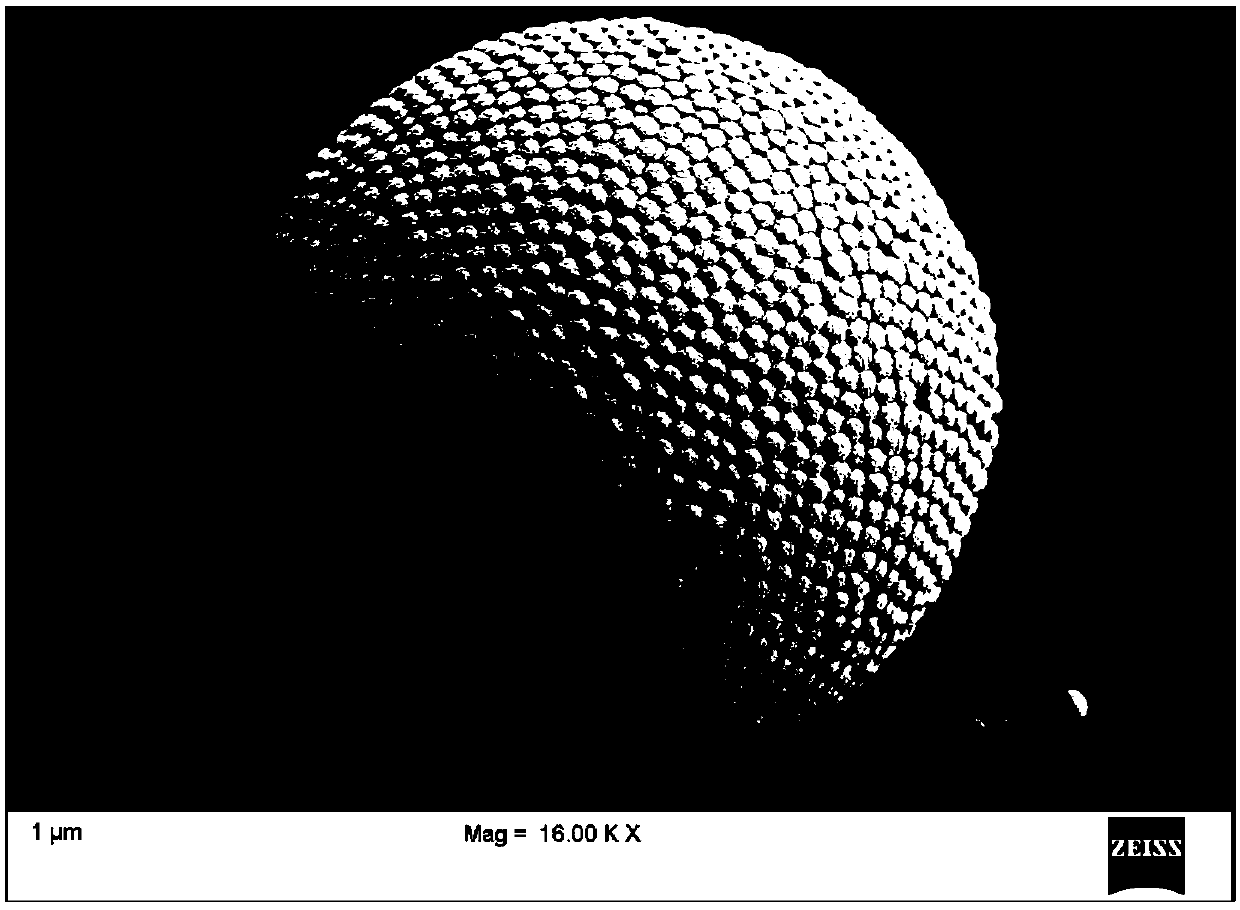

[0030] (1) Preparation of microspheres with nanoarray structure surface

[0031] Hexadecane containing 20 wt% surfactant Span80 and 5 wt% 2,2-diethoxyacetophenone initiator as the oil phase will contain 14 w / v% SiO 2 The aqueous solution of N,N isopropylacrylamide monomer of nanoparticles (with a particle size of 378 nm) was used as the aqueous phase, and the cross-linking agent N’N-methylenebisacrylamide was added thereto. The above-mentioned two-phase fluid is introduced into the flow-focused microfluidic chip of polydimethylsiloxane through a fluid pump to prepare monodisperse droplets. Since the droplets are wrapped with a certain concentration of nanoparticles, due to the influence of nanoparticles The electrostatic repulsion between them and the reduction of the free energy on the surface of the droplet make the nanoparticles arranged in an orderly manner on the surface of the micron droplet to form a nano-hexagonal array pattern, and irradiate with UV light to obtain a ...

Embodiment 2

[0037] This example is basically the same as Example 1, except that in this example, the preparation of the microspheres with nano-array structure surface is to use the method of interfacial self-assembly to prepare monodisperse microspheres with nanoparticle arrays on the surface.

[0038] The specific steps of the method of interfacial self-assembly are as follows: first, put the above-mentioned oil-water two-phase fluid in a beaker according to a certain volume ratio, stir at room temperature, emulsify to obtain a large number of droplets, and then the droplets are wrapped Driven by the liquid-liquid interfacial tension and electrostatic interaction, the nanoparticles are arranged on the surface of the droplet, forming a droplet whose surface is modified by the nanoarray structure. Then ultraviolet light irradiates the liquid droplets, solidifies, and obtains monodisperse microspheres with nanoparticle arrays on the surface, and then deposits a layer of metal layer on the su...

Embodiment 3

[0040] Hexadecane containing 20 wt% surfactant Span80 and 5 wt% 2,2-diethoxyacetophenone initiator as the oil phase will contain 14 w / v% SiO 2 The aqueous solution of N,N isopropylacrylamide monomer of nanoparticles (with a particle size of 378 nm) was used as the aqueous phase, and the cross-linking agent N’N-methylenebisacrylamide was added thereto. The above-mentioned two-phase fluid is introduced into the flow-focused microfluidic chip of polydimethylsiloxane through a fluid pump to produce a monodisperse emulsion, followed by UV curing to obtain microspheres with nano-arrays on the surface, and then used The magnetron sputtering method precisely controls the deposition time and deposits metal layers of different thicknesses on the surface of the microspheres to adjust the size of the slit between the metal and nanoparticles. Figure 5 The surface topography of the nano-arrays deposited on the surface of the microsphere at 103 nm, 205 nm, and 351 nm is shown, from Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com