A kind of reinforced and toughened polylactic acid composite material and preparation method thereof

A composite material, strengthening and toughening technology, applied in the field of biodegradable polymer materials, can solve the problems of reducing strength and rigidity, and achieve the effect that is conducive to wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the above-mentioned reinforced and toughened polylactic acid composite material is characterized in that it comprises the following steps:

[0024] (1) Melt blending polylactic acid and filler according to the above ratio to obtain a polylactic acid composite material; the mixing conditions for melt blending are: temperature 175°C, rotation speed 50 rpm, time 5-8 minutes. Before melt blending, the polylactic acid and the filler were placed in a vacuum oven and dried in vacuum at 80°C for 24h. After melting and blending, the composite material is directly cooled at room temperature and air, and cut into small pieces, pressed into 1mm thick sheets on a flat vulcanizer at 180°C under a pressure of 10MPa, and then quickly placed under the cold press for preservation. Cool to room temperature under pressure to obtain a polylactic acid composite material.

[0025] (2) The polylactic acid composite material is uniaxially stretched to obtain a reinfor...

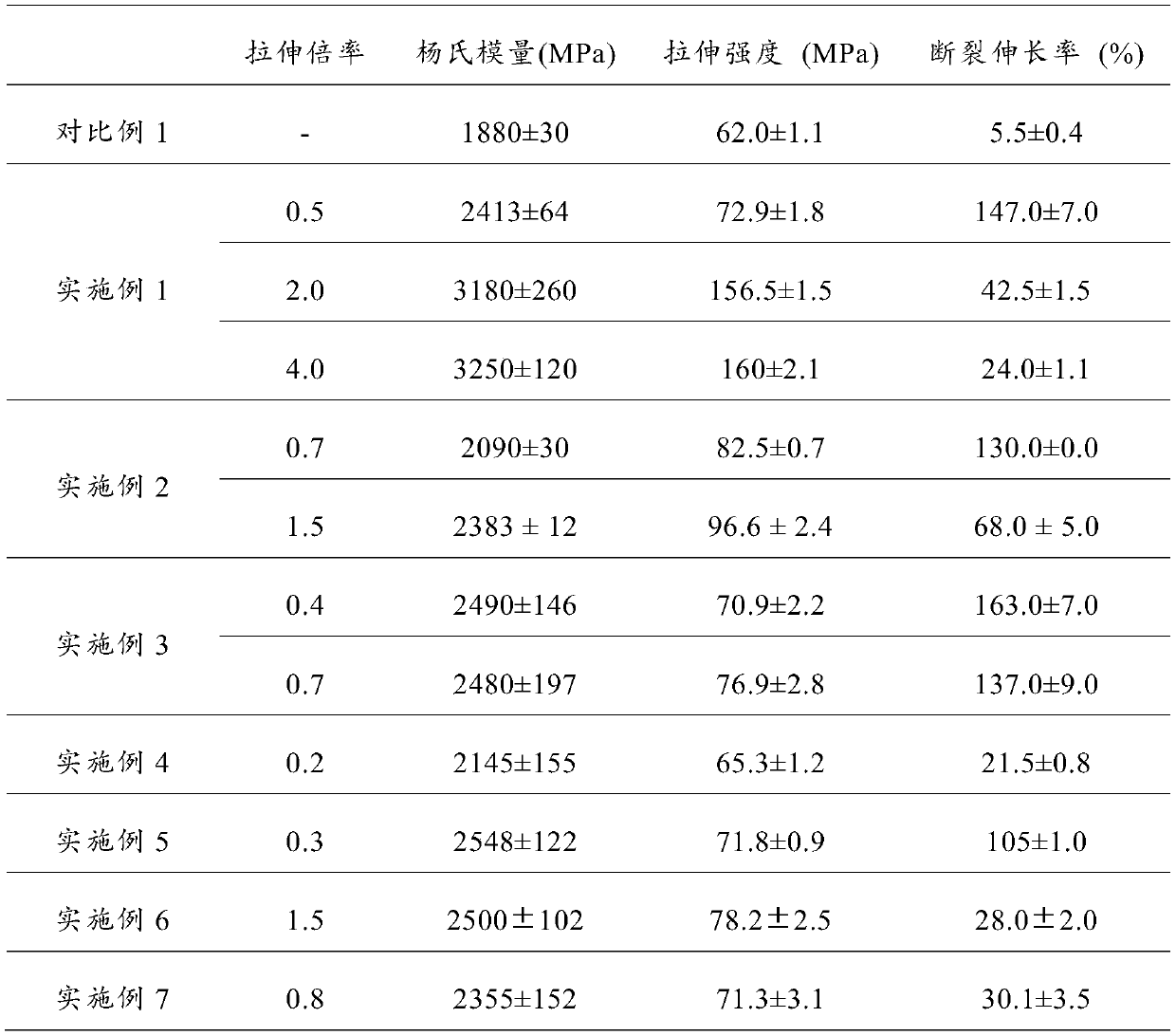

Embodiment 1

[0028] PLA (trade name is Natureworks 4032D, D-type lactic acid unit content is about 2%, weight average molecular weight is 207KDa) and nano silicon dioxide (primary particle average particle size is 15nm) are placed in a vacuum oven at 80 ℃ for vacuum drying 24h, the amount of filler added was 3wt%, weighed 58.2g PLA and 1.8g nano-silicon dioxide, and carried out melt blending in an internal mixer, the mixing conditions were: temperature 175°C, speed 50 rpm, time 5 minutes , until it is mixed evenly, the mixed sample is directly cooled at room temperature and air, and cut into small pieces, pressed into a 1mm thick sheet on a flat vulcanizer at 180 ° C under a pressure of 10 MPa, and then quickly placed in a cold Keep the pressure under the press and cool to room temperature. The pressed sheet was stretched on a universal tensile testing machine at 60°C at a tensile rate of 5mm / min to deformation ratios of 0.5 times, 2.0 times and 4.0 times, respectively, to obtain reinforce...

Embodiment 2

[0030] PLA (trade name is Natureworks 4032D, D-type lactic acid unit content is about 2%, weight average molecular weight is 207KDa) and nano-titanium dioxide (primary particle average particle size is 30nm) are placed in a vacuum oven at 80°C for 24h in vacuum, The amount of filler added is 2wt%. Weigh 58.8g PLA and 1.2g nano-titanium dioxide, and carry out melt blending in an internal mixer. Evenly, the mixed sample is directly cooled at room temperature and air, and cut into small pieces, pressed into a 1mm thick sheet on a flat vulcanizing machine at 180°C under a pressure of 10MPa, and then quickly placed under the cold press for preservation Cool to room temperature under pressure. The pressed sheet was stretched on a universal tensile testing machine at 60°C at a tensile rate of 5mm / min to a deformation ratio of 0.7 times and 1.5 times respectively to obtain a reinforced and toughened PLA composite material, and the enhanced and toughened PLA composite material was meas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com