A kind of heat-conducting plastic and preparation method thereof

A technology of thermally conductive plastics and thermally conductive additives, applied in the field of polymer materials, can solve the problems of decreased mechanical properties of materials, high price, easy combustion, etc., and achieve the effects of improving crystallization performance, accelerating crystallization rate, and small mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

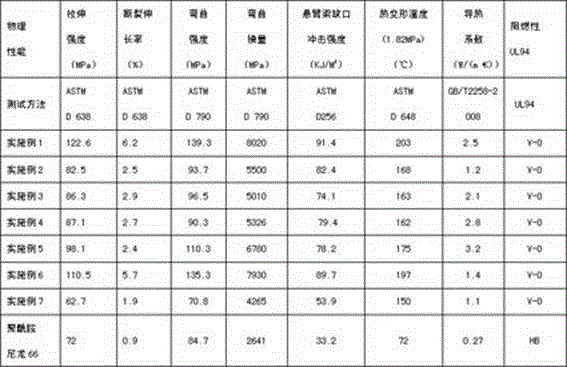

Embodiment 1

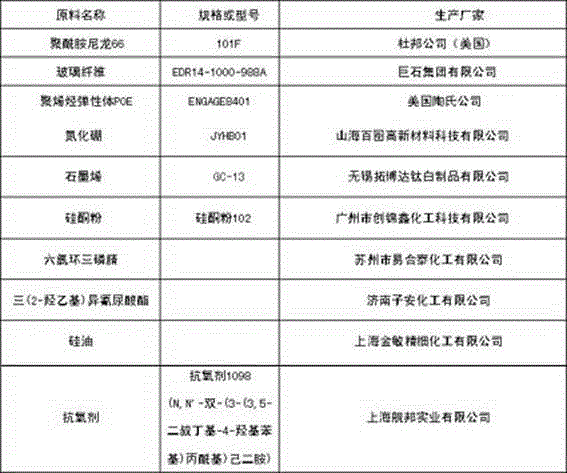

[0075] A heat-conducting plastic, calculated by weight percentage, its composition and content are as follows:

[0076] Thermoplastic resin 40%

[0077] Fiberglass 30%

[0078] Toughener 5%

[0079] Flame retardant 10%

[0080] Thermal conductivity additive 10%

[0081] Lubricant 2%

[0082] Dispersant 2.7%

[0083] Antioxidant 0.3%;

[0084] Wherein, the thermoplastic resin is polyamide nylon 66;

[0085] The glass fiber is an alkali-free long glass fiber whose surface is treated with a silane coupling agent;

[0086] The thermal conductivity aid boron nitride;

[0087] Described toughening agent is polyolefin elastomer POE;

[0088] The flame retardant is a mixture of polyaminocyclotriphosphazene and three (2-hydroxyethyl) isocyanurate in a mass ratio of 1:1;

[0089] Described lubricant is silicone powder;

[0090] Described dispersant is silicone oil;

[0091] Described antioxidant is antioxidant 1098.

[0092] The preparation method of the above-mentioned the...

Embodiment 2

[0099] A heat-conducting plastic, calculated by weight percentage, its composition and content are as follows:

[0100] Thermoplastic resin 55%

[0101] Fiberglass 20%

[0102] Toughener 5%

[0103] Flame retardant 10%

[0104] Thermal conductivity additive 5%

[0105] Lubricant 2%

[0106] Dispersant 2.7%;

[0107] Antioxidant 0.3%;

[0108] Wherein said thermoplastic resin is polyamide nylon 66;

[0109] The glass fiber is an alkali-free long glass fiber whose surface is treated with a silane coupling agent;

[0110] Described toughening agent is polyolefin elastomer POE;

[0111] The flame retardant is a mixture of polyaminocyclotriphosphazene and tris(2-hydroxyethyl)isocyanurate in a mass ratio of 1:1;

[0112] Described heat conduction aid is boron nitride;

[0113] Described lubricant is silicone powder;

[0114] Described dispersant is silicone oil;

[0115] Described antioxidant is antioxidant 1098.

[0116] The preparation method of the above-mentioned th...

Embodiment 3

[0118] A heat-conducting plastic, calculated by weight percentage, its composition and content are as follows:

[0119] Thermoplastic resin 50%

[0120] Fiberglass 20%

[0121] Toughener 5%

[0122] Thermal conductivity additive 10%

[0123] Flame retardant 10%

[0124] Lubricant 2%

[0125] Dispersant 2.7%

[0126]Antioxidant 0.3%;

[0127] Wherein said thermoplastic resin is polyamide nylon 66;

[0128] The glass fiber is an alkali-free long glass fiber whose surface is treated with a silane coupling agent;

[0129] Described toughening agent is polyolefin elastomer POE;

[0130] The flame retardant is a mixture of polyaminocyclotriphosphazene and tris(2-hydroxyethyl)isocyanurate in a mass ratio of 1:1;

[0131] Described heat conduction aid is boron nitride;

[0132] Described lubricant is silicone powder;

[0133] Described dispersant is silicone oil;

[0134] Described antioxidant is antioxidant 1098.

[0135] The preparation method of the above-mentioned the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com