Impact-resistant and high-abrasion-resistant rubber stock bin lining plate with ultrastrong self-cleaning performance

A self-cleaning, impact-resistant technology, which is applied in the field of dock material transfer, reloading equipment, and mines, can solve problems such as impact resistance, maintenance and shutdown losses, and specific gravity, so as to improve impact resistance, reduce impact loads, and increase buffering effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

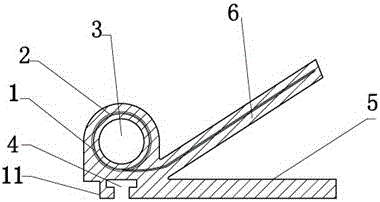

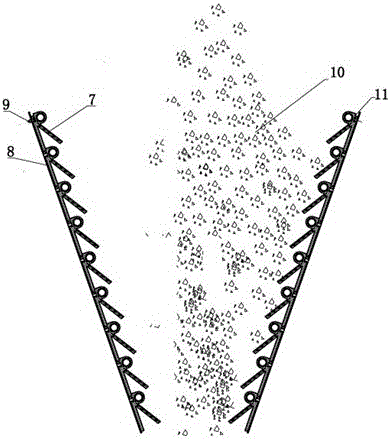

[0014] Such as figure 1 As shown, the rubber liner 7 is a whole, made of high-performance rubber and reinforced fabric skeleton composite vulcanization, the shape is R-shaped, including a semicircular stop 2, a fabric skeleton 1, a circular through hole 3, A flat liner 5 and a self-cleaning fin 6 are provided with a T-shaped lag bolt installation groove 4 . The outside of the semicircular block 2 is semicircular, which is used to change the impact angle of the material more effectively; a multi-layer polyester mesh fabric skeleton 1 is arranged inside, which is used to further enhance the overall impact resistance of the lining board and improve the impact resistance of the lining board. Life; there is a circular through hole 3 in the middle, which is used to increase the buffer capacity more effectively, reduce the material impulse, and protect the chute wall; the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com