Method of taking micro-emulsion as precursor to rapidly prepare aerogel

A microemulsion and aerogel technology, applied in chemical instruments and methods, ceramic products, inorganic chemistry, etc., can solve the problems of large amount of organic solvent and long process, and achieve good compatibility, low cost, and reduced impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

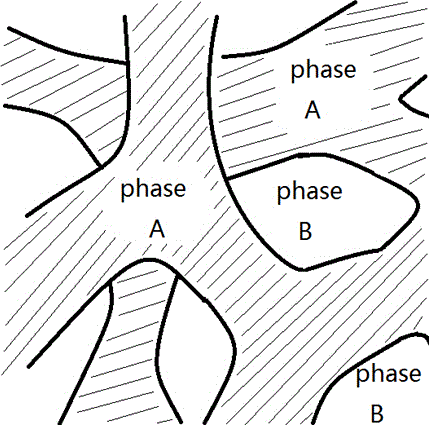

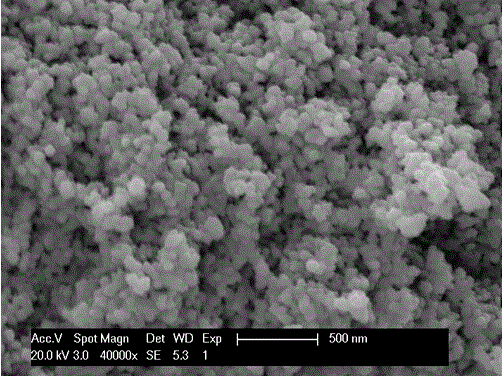

[0027] 1. Prepare 500ml airgel alkaline silica sol by microemulsion method and normal pressure drying. While stirring at high speed, add water 650ml, dioctyl sodium sulfosuccinate 30g, acetone 20g, n-hexane 350g, methyl triethoxy 150g of base silane, stir at high speed until a translucent and uniform microemulsion is obtained, add a small amount of sulfuric acid aqueous solution, adjust the pH to 8, stir at high speed for 10min, then pour into the mold and let it stand for 40 minutes, the microemulsion turns into a translucent blue-white gel ; Place the gel in ethanol at 60°C for 1 hour. During the aging process, effectively seal and add a small amount of ethanol to prevent the gel from breaking due to solvent volatilization. After aging, put the gel in a blast drying oven at 150°C and dry for 2 hours to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com