Sewage treatment device capable of recovering methane and ammonia simultaneously

A sewage treatment device and ammonia recovery technology, applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low treatment efficiency, high energy consumption, complex structure, etc. , to achieve the effect of strong adaptability, avoiding blocking and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

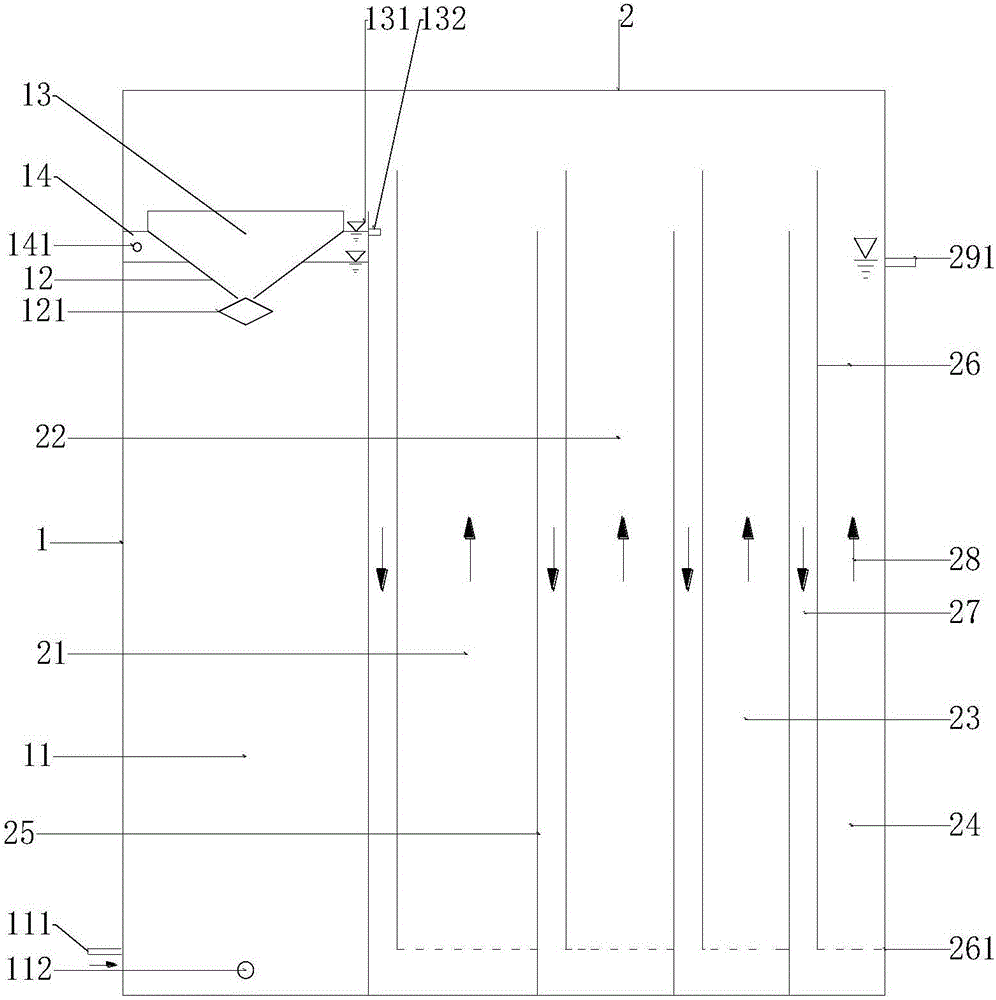

[0020] Embodiment 1 A sewage treatment device that simultaneously realizes the recovery of biogas and ammonia according to the present invention includes a reactor body, and the inner chamber of the reactor body is divided into sequentially connected up-flow exhaust chambers through vertical baffles. The oxygen sludge bed unit 1 and the baffle ion exchange unit 2, the upflow anaerobic sludge bed unit 1 communicates with the front compartment of the baffle ion exchange unit 2 through the water outlet, the The upflow anaerobic sludge bed unit 1 is, from bottom to top, a reaction zone 11 for filling anaerobic granular sludge, a three-phase separation zone equipped with a three-phase separator 12, a settling zone 13 and a set with an air outlet 141 Air chamber 14, the bottom of the reaction zone 11 is provided with a water inlet 111 and a mud discharge port 112; the gas collection chamber 14 is surrounded by the periphery of the three-phase separation zone, and the three-phase sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com