Mildew-resistant dry powder coating

A dry powder coating and anti-mildew technology, applied in the field of coatings, can solve problems such as environmental pollution and reproduction, and achieve the effects of convenient production and use, improved antibacterial properties, and improved anti-mildew properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

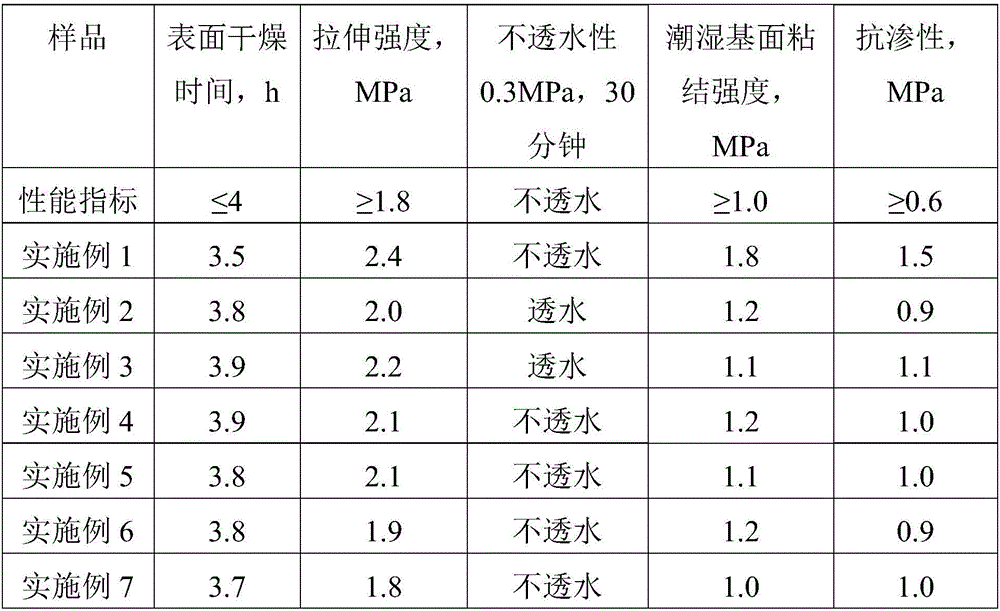

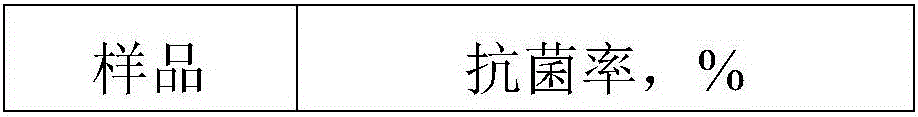

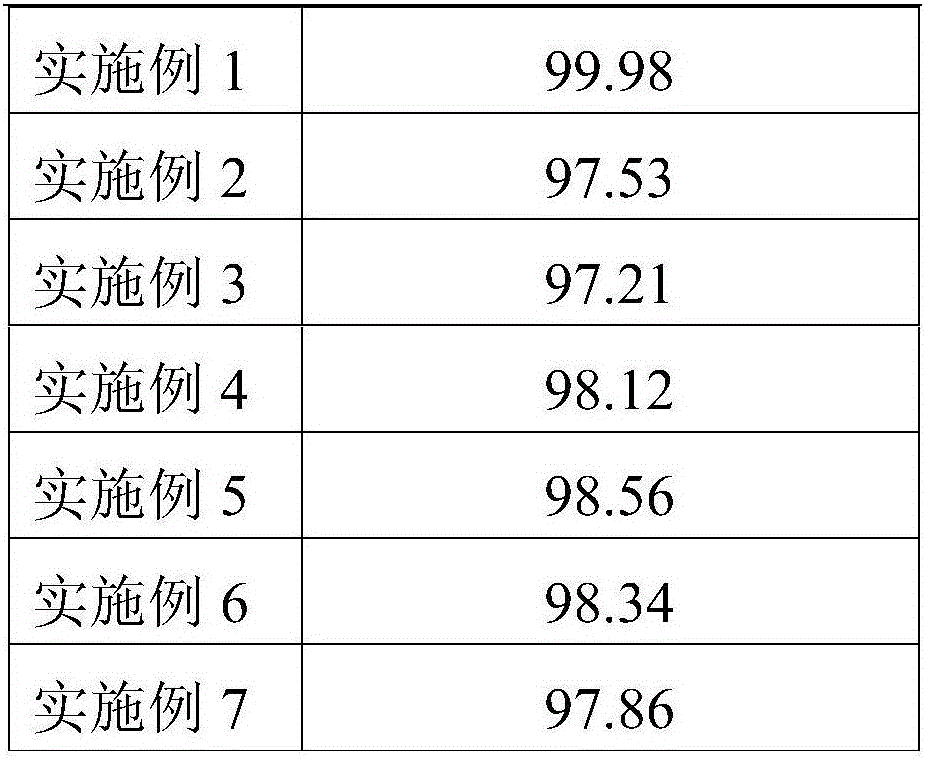

Examples

Embodiment 1

[0028] Anti-mildew dry powder coating raw materials (parts by weight):

[0029] 50 parts of cement, 40 parts of redispersible rubber powder, 20 parts of titanium dioxide, 2.5 parts of silver oxide, 5 parts of cetylpyridinium chloride, 15 parts of accelerator, 6 parts of anti-mold additive.

[0030] The anti-mildew additive is obtained by uniformly stirring and mixing zinc oxide, magnesium oxide and zirconium carbonate in a mass ratio of 1:1:1.

[0031] The quick-setting agent is obtained by stirring and mixing potassium silicate, potassium sulfate and strontium carbonate in a mass ratio of 1:1:1.

[0032] The preparation method of anti-mildew dry powder coating: mix cement, redispersible rubber powder, titanium dioxide, silver oxide, cetylpyridinium chloride, quick-setting agent, and anti-mold additives for 15 minutes with a cantilever double-helix conical mixer and mix them evenly. .

Embodiment 2

[0034] It is basically the same as in Example 1, except that the anti-mold additive is obtained by stirring and mixing zinc oxide and magnesium oxide in a mass ratio of 1:1. Obtain the anti-mildew dry powder coating of embodiment 2.

Embodiment 3

[0036] It is basically the same as in Example 1, except that the anti-mold additive is obtained by stirring and mixing zinc oxide and zirconium carbonate at a mass ratio of 1:1. Obtain the anti-mildew dry powder coating of embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com