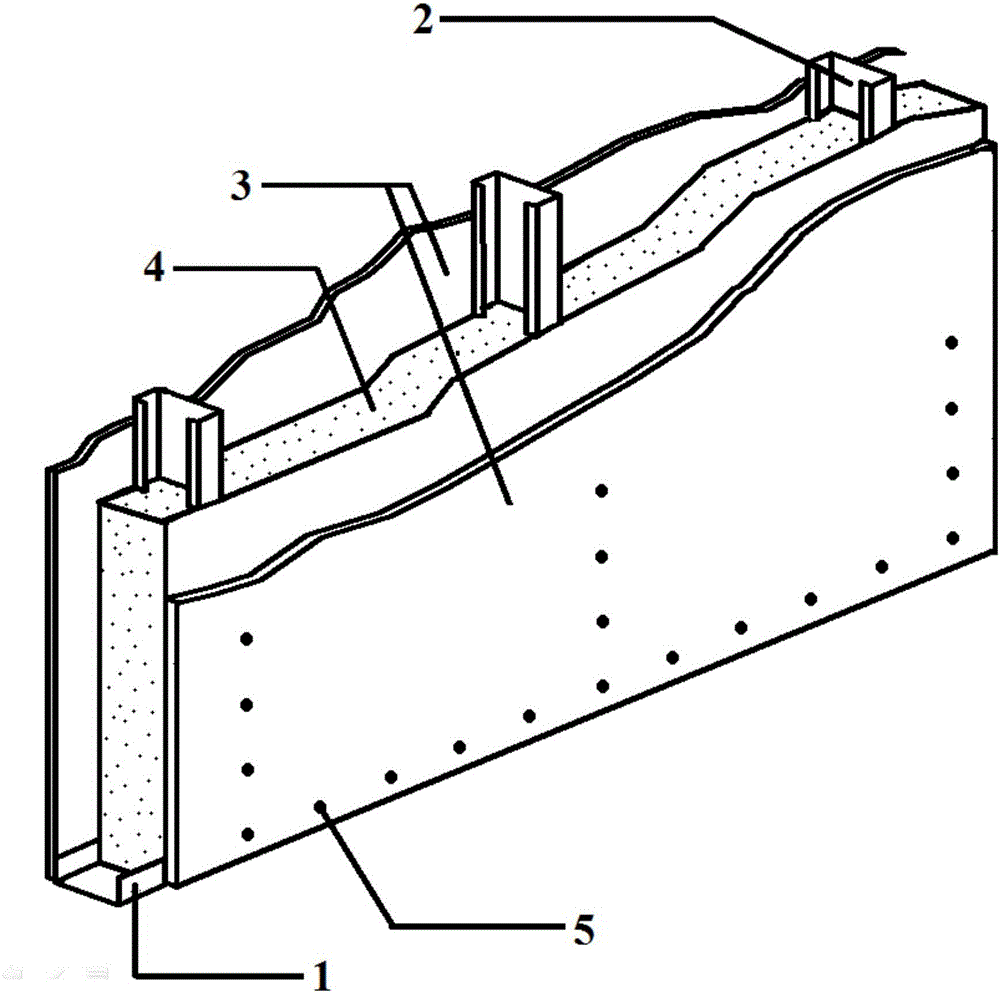

Flue gas desulfurization gypsum-based thermal insulation mortar and lightweight cold-bending thin-wall type steel composite wall

A technology of cold-formed thin-walled steel and desulfurized gypsum, which is applied to walls, building components, buildings, etc., can solve the problems of no contribution to the bearing capacity of thermal insulation cotton, no increase in utilization, and inability to share the force of the wall. Achieve the effect of ensuring volume stability, good thermal insulation performance and good construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: lightweight aggregate is polystyrene particle

[0037] This embodiment provides a desulfurized gypsum-based thermal insulation slurry, which is composed of the following raw materials in terms of weight fraction: 52.69kg of desulfurized gypsum, 9.88kg of cement, 3.29kg of fly ash, and 0.78kg of lightweight aggregate. The water agent is 0.99kg, the retarder is 0.15kg, the air-entraining agent is 0.33kg, the thickener is 0.03kg, the fiber is 2.58kg, the balance is water, and the weight percentage sum of the raw materials is 100%.

[0038] in:

[0039] The lightweight aggregate is polystyrene particles.

[0040] The setting retarder is citric acid, sodium tripolyphosphate, sodium polyphosphate or borax, preferably citric acid.

[0041] The thickener is hydroxypropylmethylcellulose, hydroxyethylcellulose, hydroxypropylcellulose or carboxymethylcellulose, preferably hydroxypropylmethylcellulose.

[0042] The water reducer is a polycarboxylate high performanc...

Embodiment 2

[0047] Example 2: The lightweight aggregate is polystyrene particles without air-entraining agent

[0048] This embodiment provides a desulfurized gypsum-based thermal insulation slurry, which is composed of the following raw materials in terms of weight fraction: 53.78 kg of desulfurized gypsum, 10.00 kg of cement, 3.26 kg of fly ash, and 0.52 kg of lightweight aggregate. The water agent is 1.01kg, the retarder is 0.16kg, the thickener is 0.04kg, the fiber is 3.76kg, the balance is water, and the weight percentage sum of raw materials is 100%.

[0049] in:

[0050] The lightweight aggregate is polystyrene particles.

[0051] The retarder is a composition of citric acid and sodium tripolyphosphate according to the mass ratio of 1:1, or a composition of sodium polyphosphate and borax according to the mass ratio of 1:1, preferably citric acid and sodium tripolyphosphate according to the mass ratio of 1 :1 composition.

[0052] The thickener is a composition of hydroxypropyl met...

Embodiment 3

[0057] Example 3: The lightweight aggregate is polystyrene particles without fibers

[0058] This embodiment provides a desulfurized gypsum-based thermal insulation slurry, which is composed of the following raw materials in terms of weight fractions: 51.64 kg of desulfurized gypsum, 9.68 kg of cement, 3.23 kg of fly ash, and 0.99 kg of lightweight aggregate. The water agent is 0.97kg, the retarder is 0.17kg, the air-entraining agent is 0.51kg, the thickener is 0.05kg, the balance is water, and the weight percentage sum of raw materials is 100%.

[0059] in:

[0060] The lightweight aggregate is polystyrene particles.

[0061] The retarder is a combination of citric acid, sodium tripolyphosphate, sodium polyphosphate and borax in a mass ratio of 1:1:1:1.

[0062] The thickener is a combination of hydroxypropyl methylcellulose, hydroxyethyl cellulose, hydroxypropyl cellulose and carboxymethyl cellulose in a mass ratio of 1:1:1:1.

[0063] The water reducer is a polycarboxyla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com